Slab continuous casting online roll gap measuring instrument

A technology of slab continuous casting and roll gap meter, applied in casting equipment, configuration of indicating equipment/measuring equipment, manufacturing tools, etc. The effect of prolonging the service life and improving the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

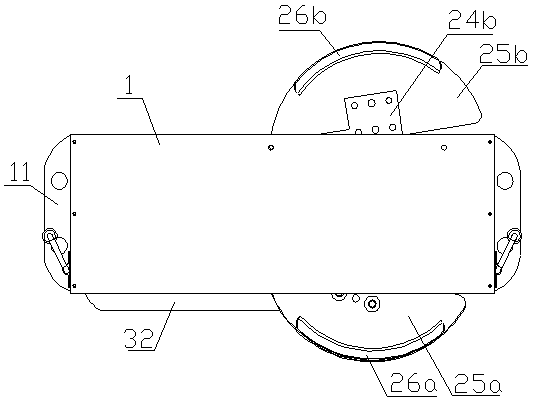

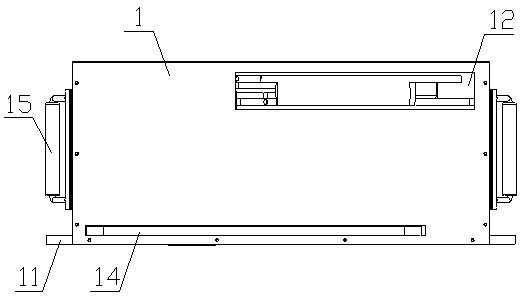

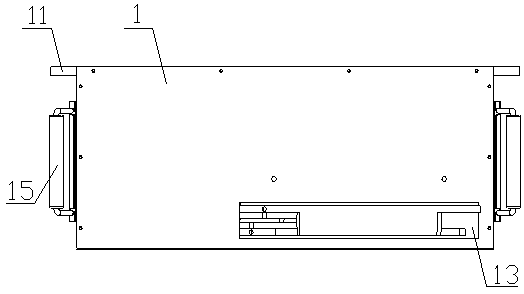

[0032] Example Figure 1 to Figure 6 As shown, a slab continuous casting online roll gap meter of the present invention includes a box body 1, a roll gap detection mechanism 2, a horizontal position switch 4, a vertical position switch 5 and a controller 6;

[0033] The bottom surface of the box body 1 is provided with an installation base plate 11, and the upper parts of the left and right sides are provided with long slots 12 and 13 for measuring seams. The controller 6 is arranged in the box body 1, and the horizontal position switch 4 and the vertical position switch 5 is arranged in the box body 1 and installed vertically, and the signal output ends of the horizontal position switch 4 and the vertical position switch 5 are respectively connected to the controller 6;

[0034] The roll gap detection mechanism 2 includes a rotating shaft 21, a rotating shaft sleeve 22, a left measuring arm 23a, a right measuring arm 23b, a left connecting plate 24a, a right connecting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com