Load-bearing car body and car body covering part for light passenger car

A technology of load-bearing body and body cover, which is applied in the field of light-weight passenger car load-bearing body and body cover, which can solve the problems of poor strength and rigidity, large self-weight, high strength and rigidity, etc., and achieve good mechanical properties, Excellent anti-corrosion performance, simple and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

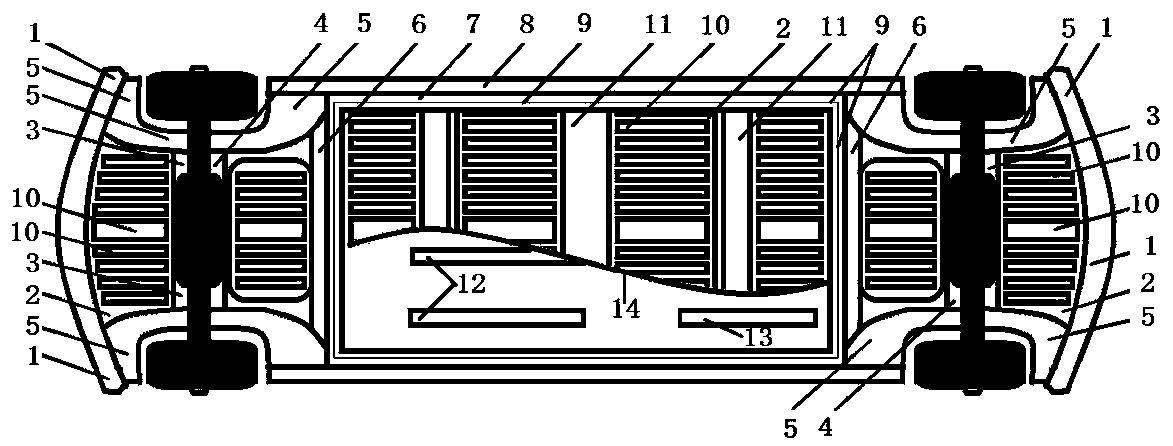

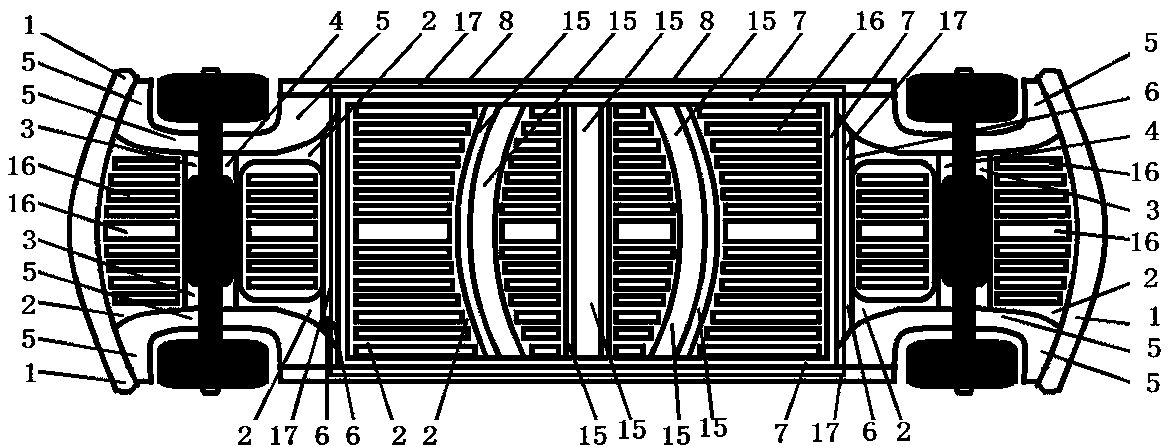

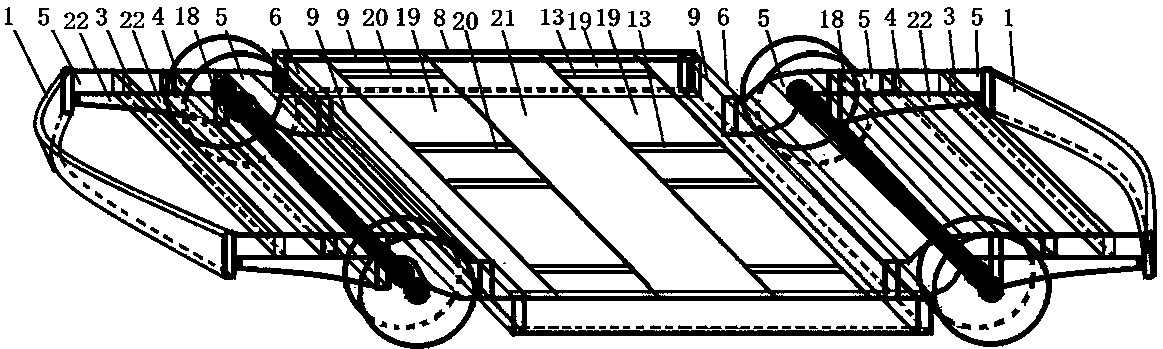

[0025] The principle and effect of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as Figures 1 to 10As shown, the wavy line 14 is exploded. The load-bearing body includes the main body and decorative parts, opening parts, mechanism parts, accessories and other detachable structural parts, and the overall body structure without an independent frame. The main body is composed of integral beams and plates, including the body of the driver's cabin in the middle, the body of the front and rear power reserve compartments of the driver's cabin, and the overall beam and plate structure is formed to ensure the strength and rigidity of the body. The body of the driver's cabin includes the front and rear reinforced main beams 6 of the driver's cabin, the left and right reinforced main longitudinal beams of the driver's cabin 8, the structural beams of the driver's cabin 19, the front driver's seat bracket and slideway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com