Aluminum diethylphosphinate with high solid-solid phase transition temperature and preparation method thereof

A technology of aluminum diethylphosphinate and diethylphosphinic acid is applied in the field of aluminum diethylphosphinate and its preparation, and can solve problems such as methods that do not involve product removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

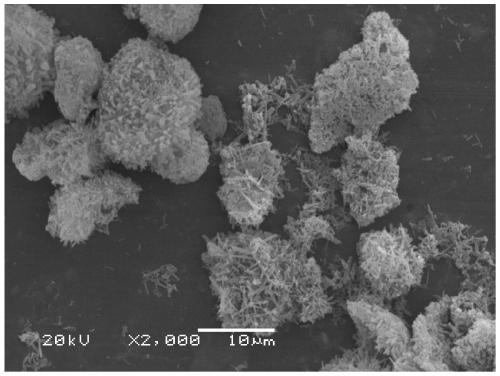

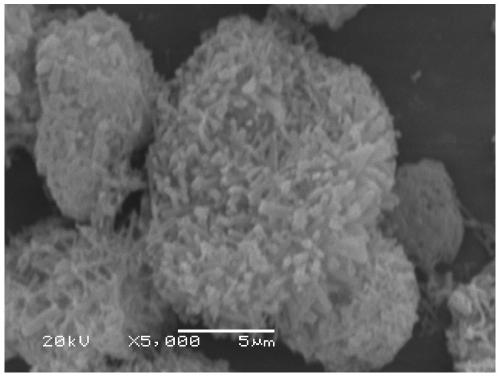

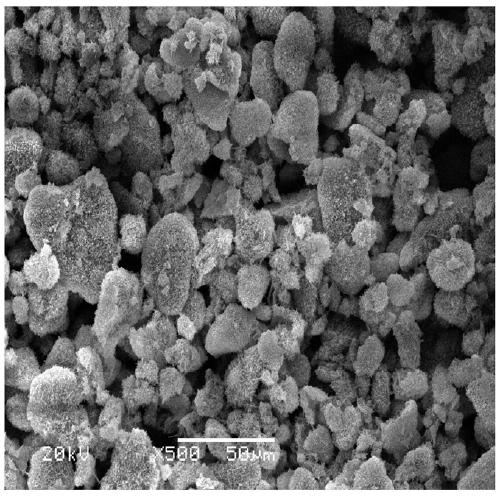

Image

Examples

preparation example Construction

[0063] In the second embodiment of the present invention, the present invention provides a method for preparing a high solid-solid phase transition temperature compound, comprising:

[0064] S1: heating the sodium diethylphosphinate solution to the first temperature, adjusting the pH, adding potassium permanganate solution dropwise, continuing the reaction and filtering to obtain a filtrate; and

[0065] S2: heat the filtrate described in S1 at a second temperature, add aluminum sulfate solution dropwise to react, and filter to obtain a precipitate; and

[0066] S3: washing and drying the precipitate described in S2 to obtain the compound.

[0067] The raw material sodium diethylphosphinate solution in the present invention is commercially available, and because of the limitation of its preparation process, all contains impurity. According to a preferred embodiment of the present invention, the concentration of the sodium diethylphosphinate solution in the sodium diethylphosp...

Embodiment 1

[0090] Sodium diethylphosphinate solution, configured as 100 liters of 12.5wt% solution, adjust the pH of the solution to 7.0 with 5% sodium hydroxide solution, then heat to 85°C, slowly add 10 g / L potassium permanganate dropwise solution, when just beginning to drop in, the purple color of potassium permanganate disappeared quickly; with the continuous addition of potassium permanganate, the fading became slower and slower, and when the added potassium permanganate solution no longer faded within 30s, Stop the dropwise addition and consume a total of 25.2L of potassium permanganate solution. Filter the mixture to obtain a treated sodium diethylphosphinate solution; in addition, dissolve 10Kg of aluminum sulfate octadecahydrate in 60Kg of water to configure an aluminum sulfate solution, and in the treated sodium diethylphosphinate solution Slowly drop into the aluminum sulfate solution filtered by activated carbon to obtain a large amount of white precipitate, filter, and wash...

Embodiment 2

[0092] Sodium diethylphosphinate solution, configured as 100 liters of 12.5wt% solution, adjusted the pH of the solution to 7.0 with 5% sodium hydroxide solution, then heated to 85°C, and slowly added dropwise 20 g / L of potassium permanganate solution, when just beginning to drop in, the purple color of potassium permanganate disappeared quickly; with the continuous addition of potassium permanganate, the fading became slower and slower, and when the added potassium permanganate solution no longer faded within 30s, Stop the dropwise addition and consume a total of 13L of potassium permanganate solution. The mixture was filtered, and the pH of the solution was adjusted to 3.0-3.8 with 5wt% dilute sulfuric acid to obtain a treated sodium diethylphosphinate solution; in addition, 10Kg of aluminum sulfate octadecadecahydrate was dissolved in 60Kg of water to form an aluminum sulfate solution. Slowly drop the aluminum sulfate solution filtered by activated carbon into the treated s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com