Temperature-resistant anti-corrosion color-changing paint and preparation method thereof

A technology of color-changing coatings and color-changing pigments, which is applied in anti-corrosion coatings, polyamide coatings, coatings, etc. Monitoring effect and other issues, to achieve the effect of bright color, strong tinting strength and sensitive color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The invention also discloses a method for preparing a temperature-resistant, anti-corrosion and color-changing coating, which includes the following steps:

[0058] (1) Add part of carboxyl-terminated hyperbranched polyamide resin, dispersant, defoamer, titanium dioxide, anti-rust pigment, hollow microspheres, color-changing pigment and active nano-calcium into deionized water in sequence, and stir evenly to make a mixed slurry ;

[0059] (2) adding the above-mentioned mixed slurry into a grinder and grinding until a uniform slurry with good fluidity is formed;

[0060] (3) Add the remaining carboxyl-terminated hyperbranched polyamide resin, graphene, anti-flash rust additive and substrate wetting agent to the slurry in turn, stir evenly, and adjust to the specified viscosity with a thickener to obtain the product Invented heat-resistant anti-corrosion discoloration paint.

[0061] In order to further optimize the above technical solution, in step (1), the stirring sp...

Embodiment 1

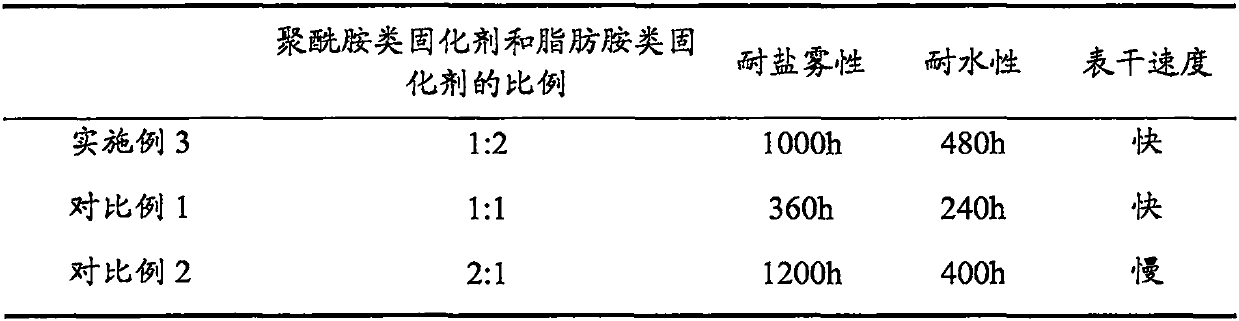

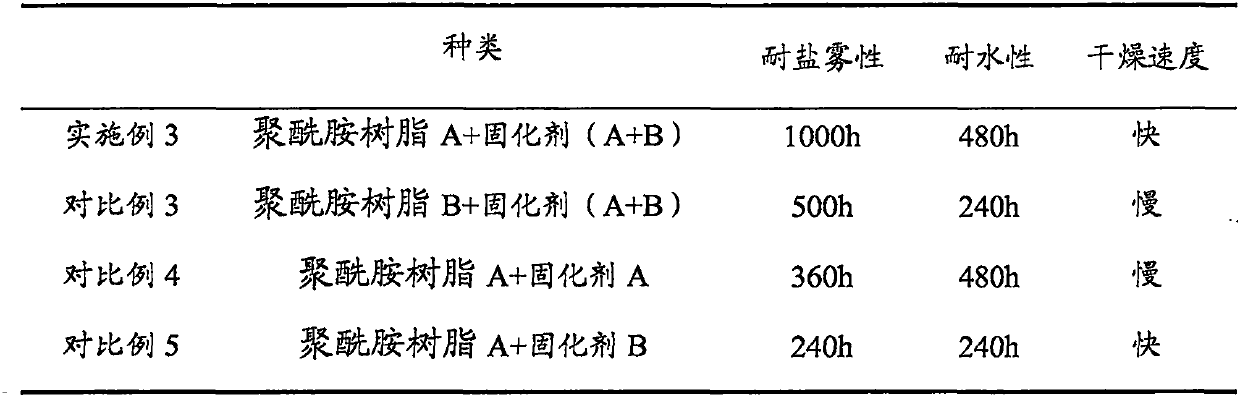

[0066] A temperature-resistant, anti-corrosion and color-changing paint, which is prepared by the following raw material ratio in terms of weight percentage: 57% of carboxyl-terminated hyperbranched polyamide resin, 10% of titanium dioxide, 5% of hollow microspheres, 5% of aluminum tripolyphosphate, active Nano-calcium 5%, graphene 0.1%, dispersant 2%, defoamer 0.1%, organic-inorganic compound anti-flash rust additive 1%, substrate wetting agent 0.5%, thickener 0.5%, deionization 20% of water, 3% of curing agent, 12% of phthalocyanine blue, wherein the carboxyl-terminated hyperbranched polyamide resin is prepared by reacting diamine, tribasic acid and amino-terminated silicone oil, and the curing agent is a polymer with a mass ratio of 1:2. A mixture of amide curing agent and aliphatic amine curing agent, the dispersant is a copolymer type dispersant with pigment affinity groups, the defoamer is a polyether siloxane copolymer type defoamer, the substrate is wet The agent is a ...

Embodiment 2

[0068] A temperature-resistant, anti-corrosion and color-changing paint, which is prepared by the following raw material ratio by weight percentage: 55% carboxyl-terminated hyperbranched polyamide resin, 12% titanium dioxide, 7% hollow microspheres, 8% aluminum tripolyphosphate, active Nano-calcium 7%, graphene 0.15%, dispersant 2.2%, defoamer 0.2%, organic-inorganic compound anti-flash rust additive 1.5%, substrate wetting agent 0.7%, thickener 0.8%, deionization 25% of water, 3.5% of curing agent, 12% of phthalocyanine blue, wherein the carboxyl-terminated hyperbranched polyamide resin is prepared by reacting diamine, tribasic acid and amino-terminated silicone oil, and the curing agent is a polymer with a mass ratio of 1:2. A mixture of amide curing agent and aliphatic amine curing agent, the dispersant is a copolymer type dispersant with pigment affinity groups, the defoamer is a polyether siloxane copolymer type defoamer, the substrate is wet The agent is a polyether silo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com