A kind of high-strength and high-toughness polyimide resin-based composite material and preparation method thereof

A high-toughness polyimide resin and polyimide resin technology are applied in the preparation of high-strength and high-toughness polyimide resin-based composite materials, and in the field of high-strength and high-toughness polyimide resin-based composite materials, which can solve the problem of toughness. , processing performance, temperature resistance and excellent mechanical properties cannot be combined, so as to achieve the effect of improving mechanical strength, improving high temperature performance and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] On the one hand, the present invention provides a kind of preparation method of high-strength and high-toughness polyimide resin-based composite material, and the method comprises:

[0029] (1) prepare polyimide resin solution;

[0030] (2) carrying out surface treatment to polyimide fiber;

[0031] (3) disperse the product obtained in step (2) in the polyimide resin solution obtained in step (1) under stirring conditions;

[0032] (4) the mixed slurry that step (3) obtains is carried out heating treatment;

[0033] (5) subjecting the product obtained in step (4) to thermocompression molding;

[0034] The polyimide fibers are at least one of polyimide fiber pulp, polyimide chopped fibers and polyimide fibrids.

[0035] According to the method of the present invention, in step (1), preferably, the solid content of the polyimide resin solution is 5-40% by weight, and the solvent used is ethanol.

[0036] More preferably, the polyimide resin is a polyimide resin contai...

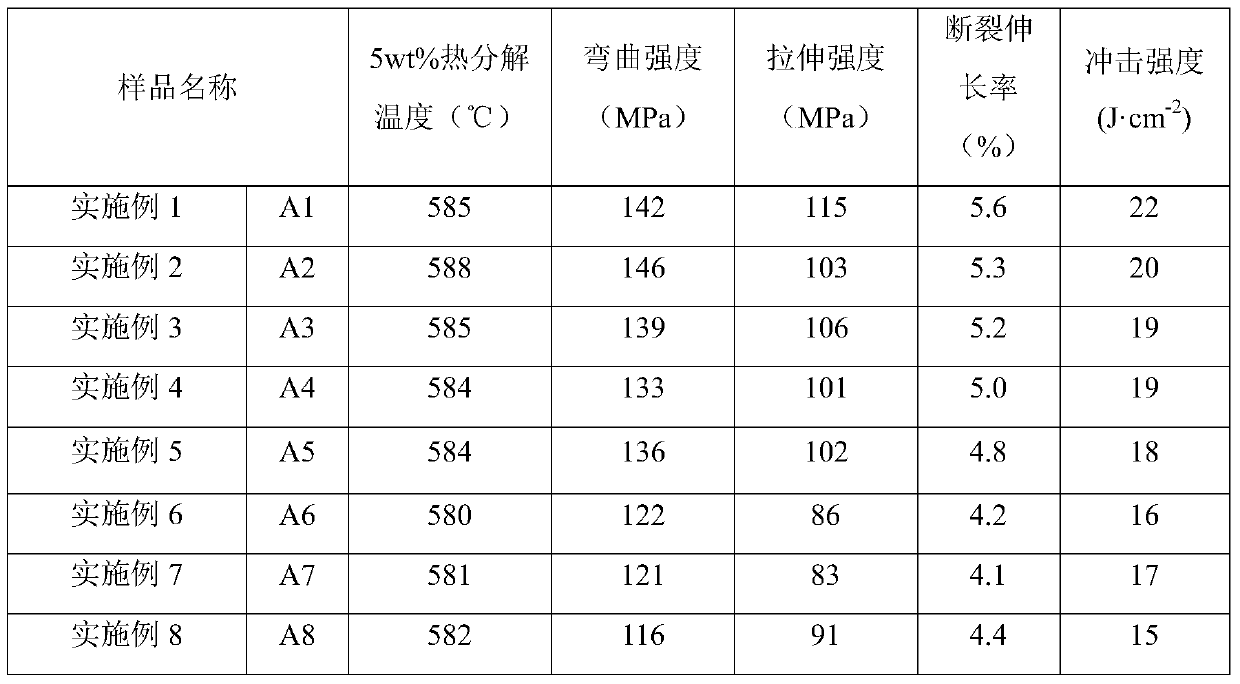

Embodiment 1

[0058] This example is used to illustrate the high-strength and high-toughness polyimide resin-based composite material of the present invention and its preparation method.

[0059] (1) adopt 1500ml 5wt% NaOH solution surface treatment 15g polyimide pulp fiber (average length is 2mm, specific surface area is 7m 2 / g) 5min;

[0060] (2) washing the product obtained in step (1) with water to neutrality;

[0061] (3) At a temperature of 40°C and a stirring speed of 600r / min, the polyimide pulp fibers obtained in step (2) were dispersed in 100g of the prepared polyimide resin solution (solid content 40%, weight average Molecular weight is 2000);

[0062] (4) Raise the mixed slurry obtained in step (3) to 240°C at a heating rate of 5°C / min, and keep it warm for 1h;

[0063] (5) Under the conditions of a temperature of 370° C. and a pressure of 6 MPa, the product obtained in step (4) was subjected to thermocompression molding for 1 hour to obtain a high-strength and high-toughnes...

Embodiment 2

[0065] This example is used to illustrate the high-strength and high-toughness polyimide resin-based composite material of the present invention and its preparation method.

[0066] (1) Under the power of 200W, oxygen plasma is used to treat 5g polyimide pulp fiber (the average length is 1mm, and the specific surface area is 11m 2 / g) carry out surface treatment 5min;

[0067] (2) washing the product obtained in step (1) with water to neutrality;

[0068] (3) At a temperature of 25°C and a stirring speed of 1000r / min, the polyimide pulp fibers obtained in step (2) were dispersed in 100g of the prepared polyimide resin solution (solid content 30%, weight average Molecular weight is 10000);

[0069] (4) Raise the mixed slurry obtained in step (3) to 220°C at a heating rate of 10°C / min, and keep it warm for 1h;

[0070] (5) Under the conditions of a temperature of 320° C. and a pressure of 2 MPa, the product obtained in step (4) was subjected to thermocompression molding for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com