Method for preparing super high temperature complex phase ceramic ZrB2-ZrC-SiC near to zero ablation

A technology of multiphase ceramics, zrb2-zrc-sic, applied in the field of special ceramics, can solve the problems of low production efficiency, poor thermal shock resistance, low sintering activity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

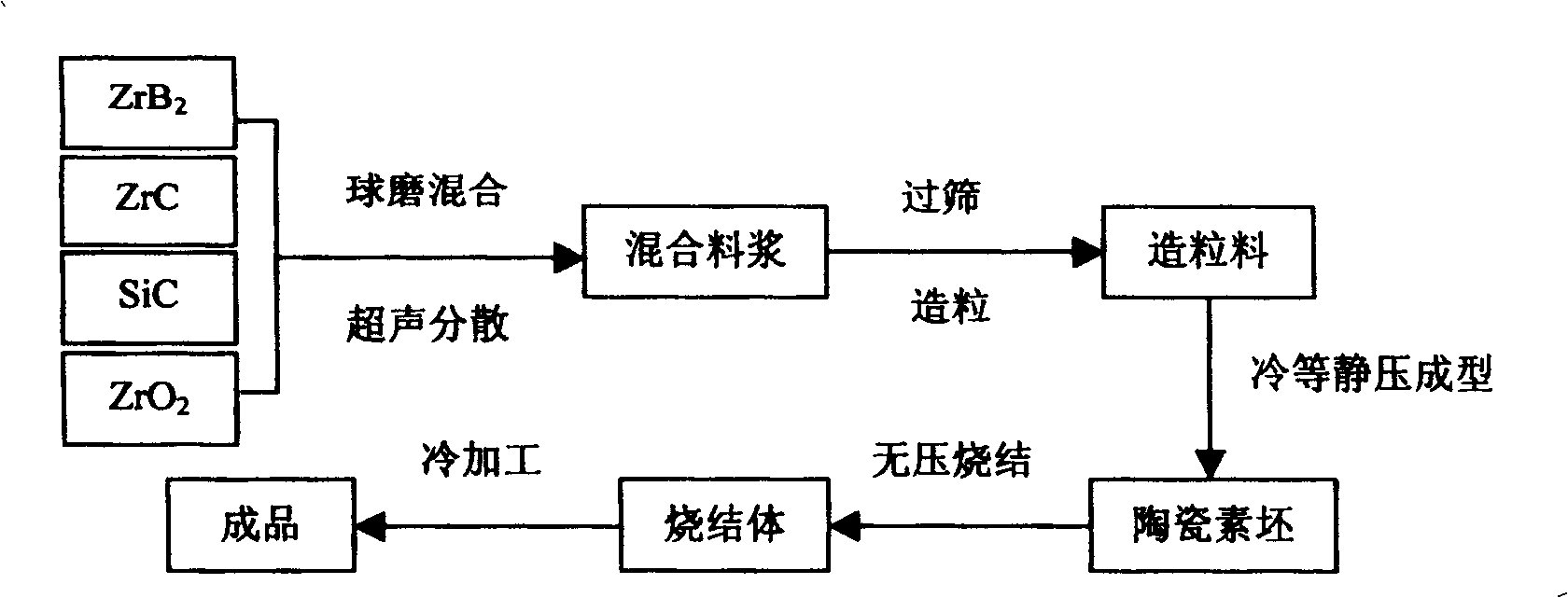

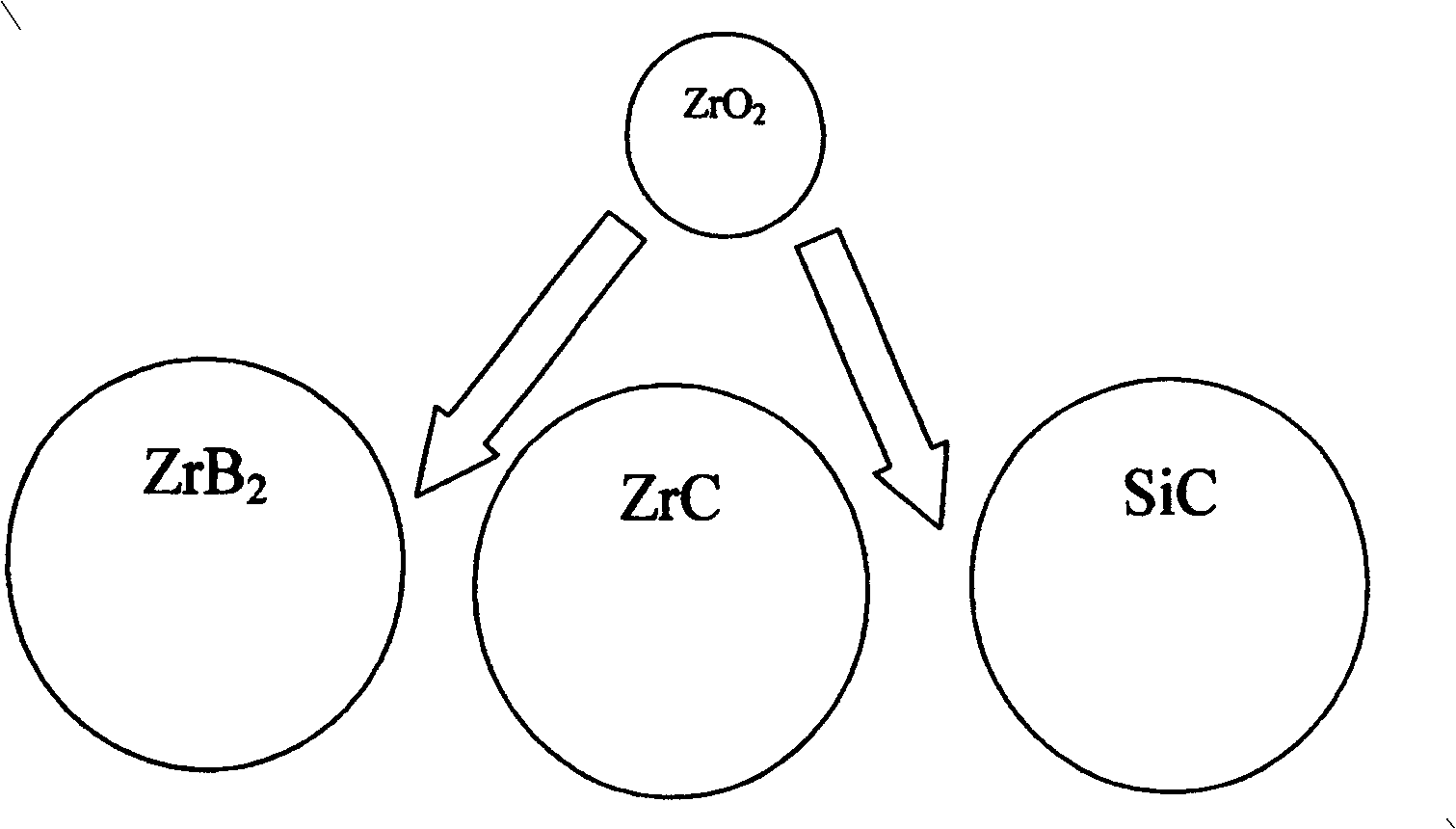

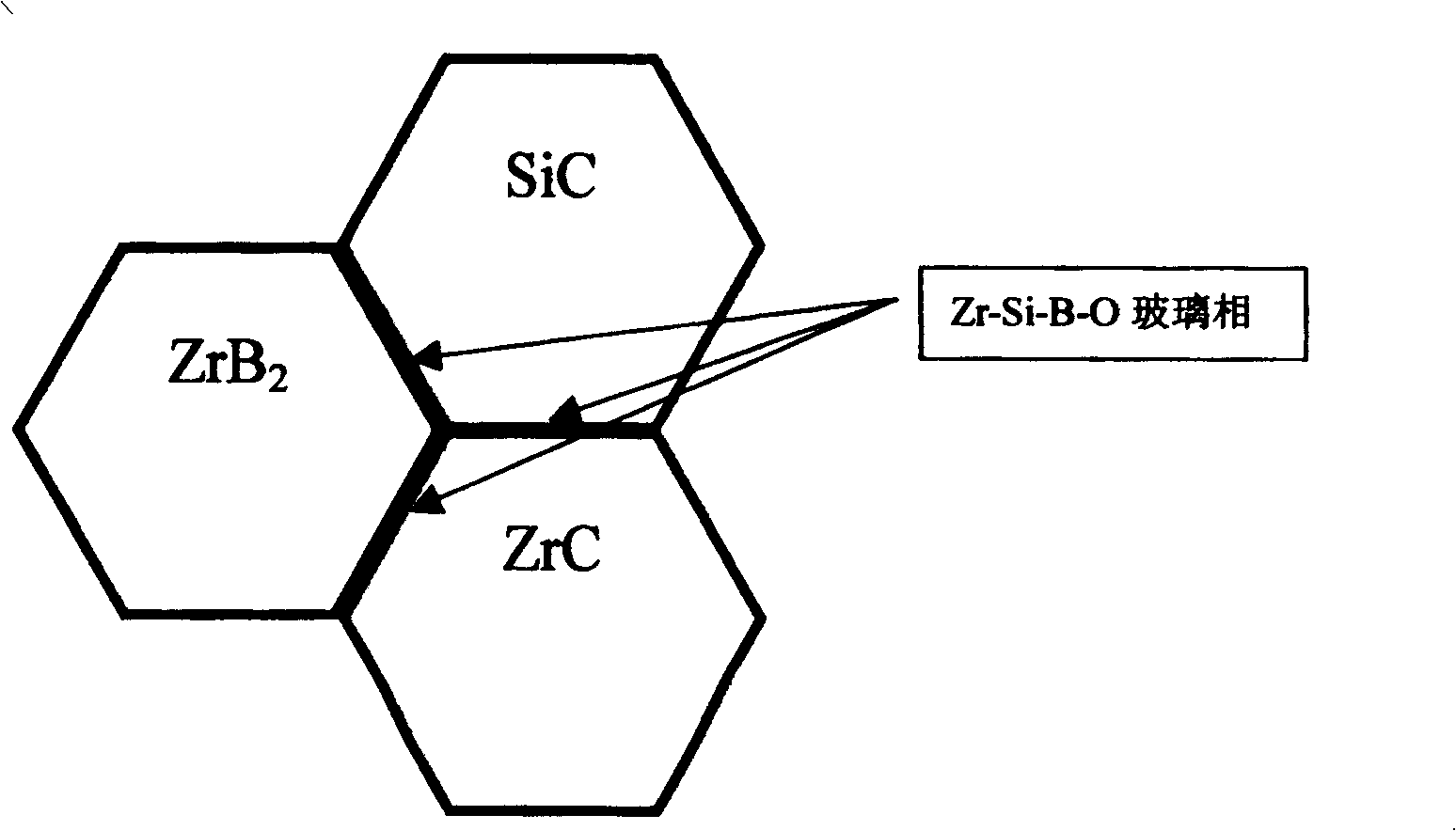

[0020] Ultra-high temperature near-zero ablation ZrB described in the present invention 2 -The preparation method of ZrC-SiC composite phase ceramics, carry out according to the following steps:

[0021] ZrB by weight 2 , ZrC and SiC and additional ZrO 2 60%, 25% and 15%, plus 12% to weigh the powder, the median particle size of the four powders are: 1.5μm, 1.3, 1.0μm and 0.5μm, using deionized water as a dispersant, Ball milling, 25KHz ultrasonic dispersion, and granulation through a centrifugal drying granulator after passing through a 300-mesh sieve. The feeding speed is 8Kg / h, the drying temperature is 200°C, and the particle size of the granulated material is 0.5-2mm. Then evenly put it into a special oil-resistant rubber abrasive tool, and shape it in a wet isostatic press with a maximum pressure of 180MPa. The formed samples were put into a pressureless sintering furnace protected by argon gas and fired at a maximum firing temperature of 1800°C for 2 hours. Let it c...

Embodiment 2

[0023] ZrB by weight 2 , ZrC and SiC and additional ZrO 2 50%, 35% and 15% respectively, plus 12% to weigh the powder, and the others are the same as in Example 1. The properties are shown in Table 1.

Embodiment 3

[0025] ZrB by weight 2 , ZrC and SiC and additional ZrO 2 70%, 20% and 10% respectively, plus 12% to weigh the powder, and the others are the same as in Example 1. The properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com