Polyimide derivatives containing triphenylamine structure and naphthalene imide fluorescent group, preparation method and application thereof

A technology of polyimide and naphthaleneimide, which is applied in the field of polyimide derivatives, can solve the problems of limiting the application of polyimide materials, poor film forming strength and transparency, and high processing difficulty, and achieve good wetting Ability, facilitated handling and application, effects of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Specific embodiment 1: In this embodiment, the structural formula of polyimide derivatives containing triphenylamine structure and naphthalimide fluorescent group is as follows:

[0034]

[0035] , where n is an integer from 3 to 10.

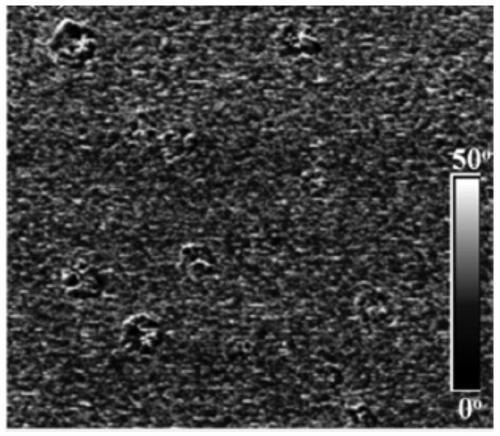

[0036] This implementation mode expands the application range of electrochromic materials. The aromatic polyimide polymer material has aroused great interest of scientific researchers due to its excellent heat resistance and mechanical properties. Introducing the triphenylamine group, which has the ability to destroy the stacking performance, into the polyimide structure, not only can maintain the high thermal stability of the original polyimide, but also can increase its solubility and enhance the film-forming ability, which is not only conducive to the manufacture of large The thin film electrochromic device of the area also provides electroactive centers to facilitate the processing and application of the electrochromic device; the ...

specific Embodiment approach 2

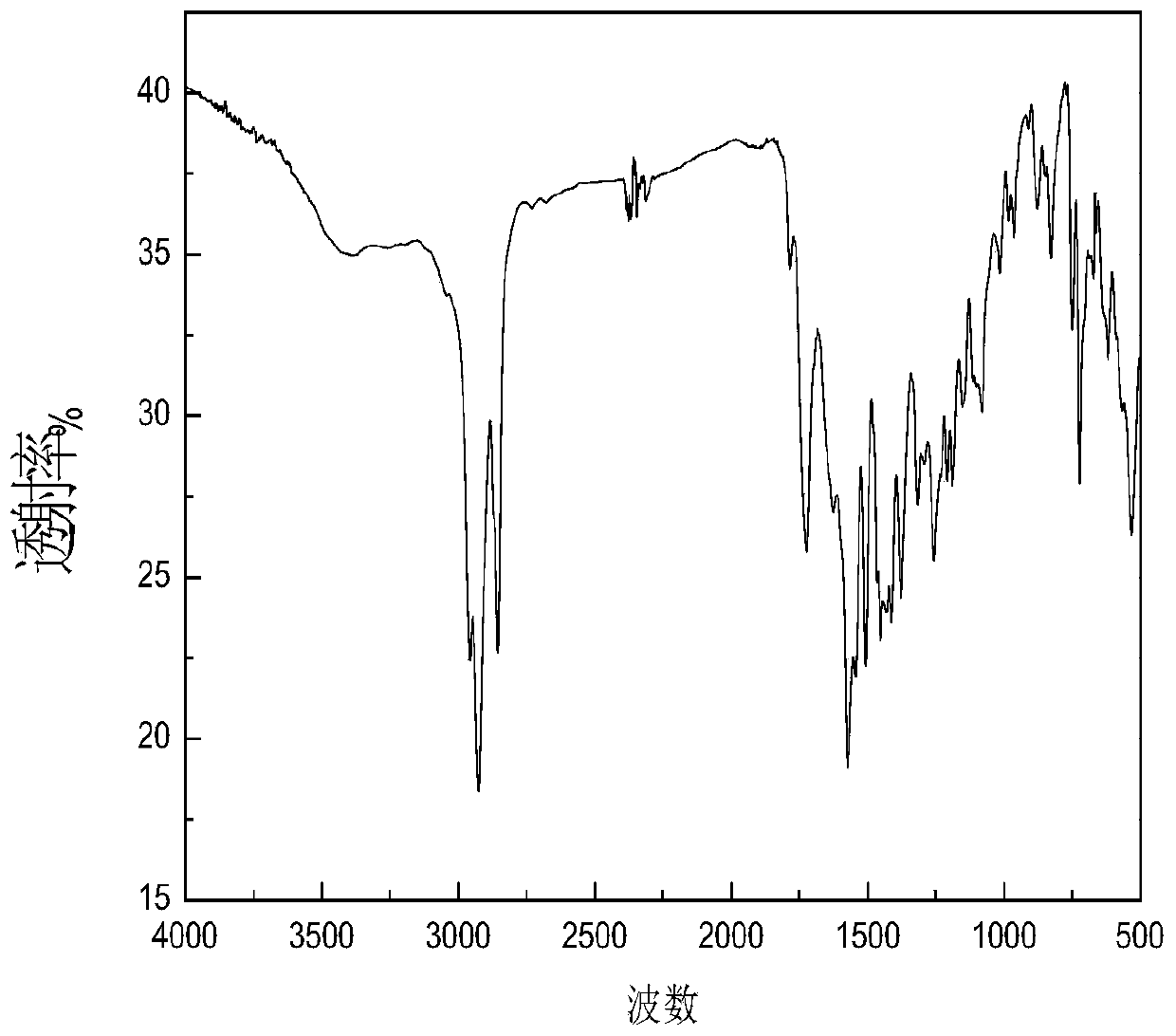

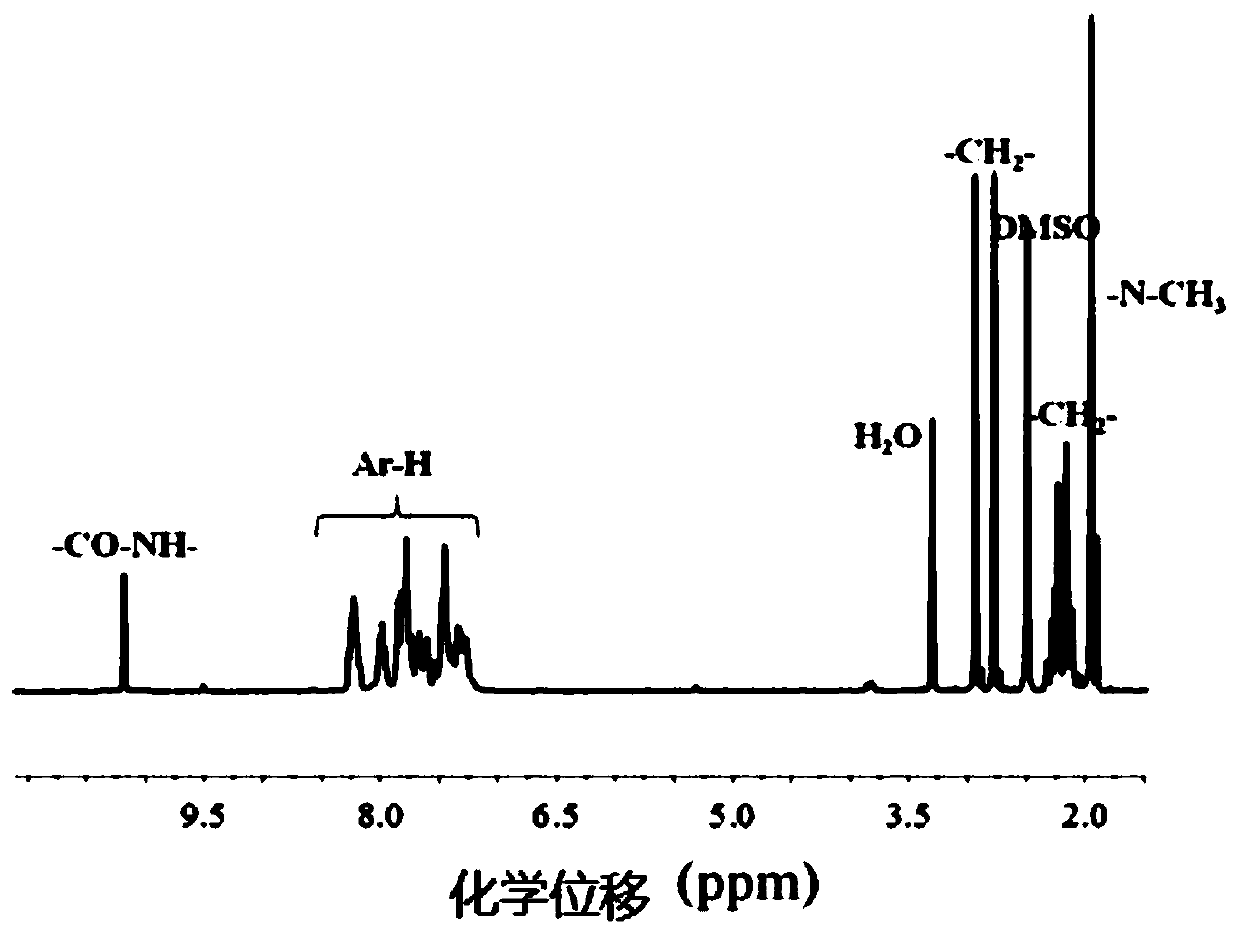

[0038]Specific embodiment two: the preparation method of polyimide derivatives containing triphenylamine structure and naphthalene imide fluorescent group in this embodiment is as follows: 1. Synthesis of polyimide precursor containing triphenylamine structure

[0039] Mix the diamine monomer containing triphenylamine, 3,3'-dihydroxyaniline, hexafluorodianhydride and the solvent N-methylpyrrolidone, stir and reflux at room temperature for 5-10h, and the stirring speed is 800r / min~900r / min min, then add acetic anhydride and catalyst pyridine, heat up to 100-150°C, stir and reflux for 10-15h, pour into methanol after cooling, filter, and vacuum-dry the obtained solid phase to obtain a polyimide precursor;

[0040] 2. Preparation of polyimide derivatives containing triphenylamine structure and naphthalimide fluorescent group

[0041] Add polyimide precursor, solvent N-methylpyrrolidone, naphthalimide derivatives containing hydroxyl structure, isocyanate MDI and catalyst dibutylti...

specific Embodiment approach 3

[0048] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the molar ratio of the diamine monomer containing triphenylamine, 3,3'-dihydroxyaniline, and hexafluorodianhydride described in step one is 1: 1:2. It is the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com