Micro-foaming polypropylene material and preparation method thereof

A polypropylene material and micro-foaming technology, applied in the field of foamed plastics, can solve the problems of poor thermoformability and poor foaming performance of micro-foamed polypropylene materials, achieve good thermoformability, strengthen rigidity, and improve foaming rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

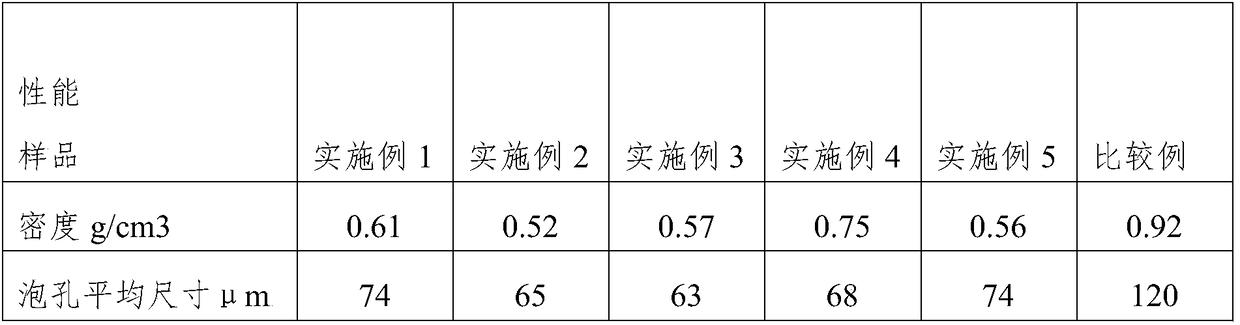

Examples

Embodiment 1

[0020] The micro-foamed polypropylene material in this embodiment is made of the following raw materials in parts by weight: 0.5 parts of halloysite nanomaterial, 3 parts of microcapsule foaming agent, and 96.5 parts of modified polypropylene;

[0021] The preparation method of the micro-foamed polypropylene material of the present embodiment comprises the following steps:

[0022] S1, weighing 0.5 parts of raw material halloysite (HNTs) nanomaterials in parts by weight, 3 parts of microcapsule foaming agent, and 96.5 parts of modified polypropylene are uniformly mixed in proportion to obtain a mixed material;

[0023] S2. The mixed material obtained in step S1 is injection-molded to prepare a micro-foamed polypropylene material under the condition of secondary mold opening.

[0024] In this example, the modified polypropylene is prepared by mixing 80 parts of polypropylene, 5 parts of compatibilizer POE, and 15 parts of talcum powder.

Embodiment 2

[0026] The micro-foamed polypropylene material in this embodiment is made of the following raw materials in parts by weight: 0.8 parts of halloysite nanomaterial, 2 parts of microcapsule foaming agent, and 97.2 parts of modified polypropylene;

[0027] The preparation method of the micro-foamed polypropylene material of the present embodiment comprises the following steps:

[0028] S1, weighing 0.8 parts by weight of raw material halloysite (HNTs) nanomaterials, 2 parts of microcapsule foaming agent, and 97.2 parts of modified polypropylene are uniformly mixed in proportion to obtain a mixed material;

[0029] S2. The mixed material obtained in step S1 is injection-molded to prepare a micro-foamed polypropylene material under the condition of secondary mold opening.

[0030] In this example, the modified polypropylene is prepared by mixing 75 parts of polypropylene, 8 parts of compatibilizer POE, and 17 parts of talcum powder.

Embodiment 3

[0032] The microfoamed polypropylene material in this embodiment is made of the following raw materials in parts by weight: 0.3 parts of halloysite nanomaterial, 2 parts of microcapsule foaming agent, and 97.7 parts of modified polypropylene;

[0033] The preparation method of the micro-foamed polypropylene material of the present embodiment comprises the following steps:

[0034] S1, weighing 0.3 parts of raw material halloysite (HNTs) nanomaterials in parts by weight, 2 parts of microcapsule foaming agent, and 97.7 parts of modified polypropylene are uniformly mixed in proportion to obtain a mixed material;

[0035] S2. The mixed material obtained in step S1 is injection-molded to prepare a micro-foamed polypropylene material under the condition of secondary mold opening.

[0036] In this embodiment, the modified polypropylene is prepared by mixing 75 parts of polypropylene and 20 parts of talcum powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com