Transmission line equivalent icing thickness monitoring system and method

A technology for icing thickness and transmission lines, applied to measuring devices, instruments, etc., can solve the problems of wire stress equivalent icing thickness error, poor monitoring data accuracy, complex and cumbersome operation process, etc., to achieve accurate results and meet early warning , reasonable effect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

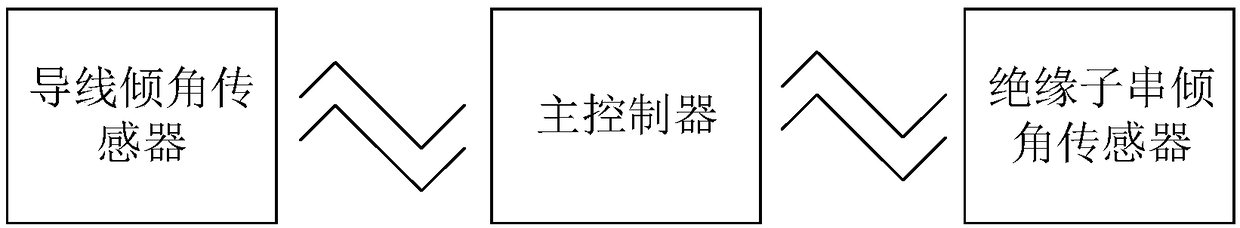

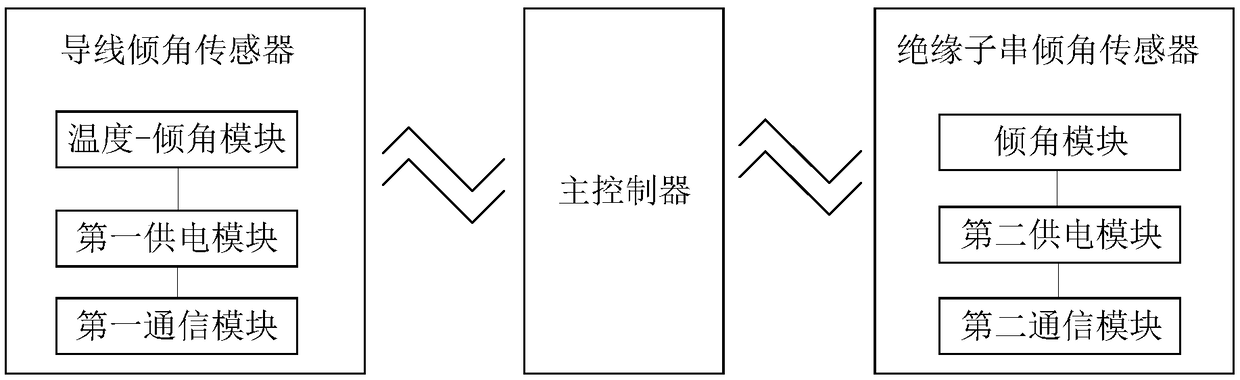

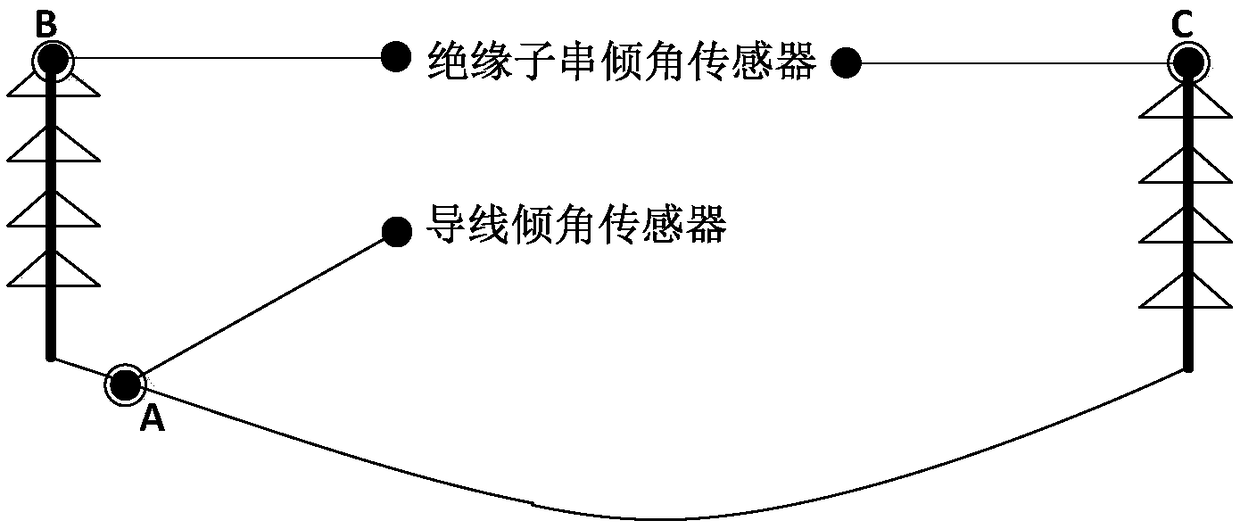

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a kind of transmission line equivalence icing thickness monitoring system, comprises wire inclination angle sensor (output wire temperature value and wire inclination angle value), insulator string inclination angle sensor, main controller; Wire inclination angle sensor is installed in At the hanging point of the wire, the insulator string inclination sensor is installed on the hanging insulator string, and the main controller is installed on the cross arm of the tower. Specifically, the communication connection may be a wireless communication connection or a wired comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com