Sealing performance detection method for battery liquid injection port sealing structure

A technology of airtightness detection and detection method, which is applied in the field of airtightness detection of the sealing structure of the battery liquid injection port, can solve the problems of unreliability, complicated device, increased production cost, etc., and achieve the effect of high accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Detection method of the present invention comprises the steps:

[0062] Pressurized helium stage:

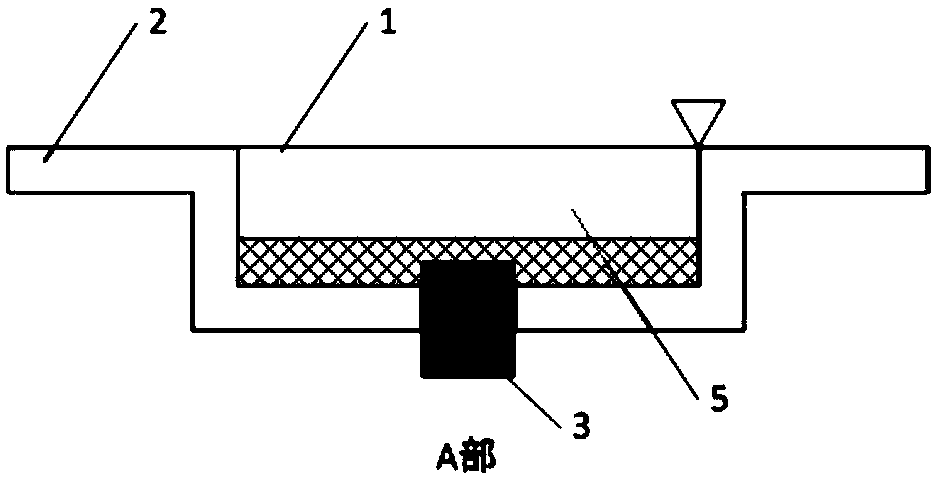

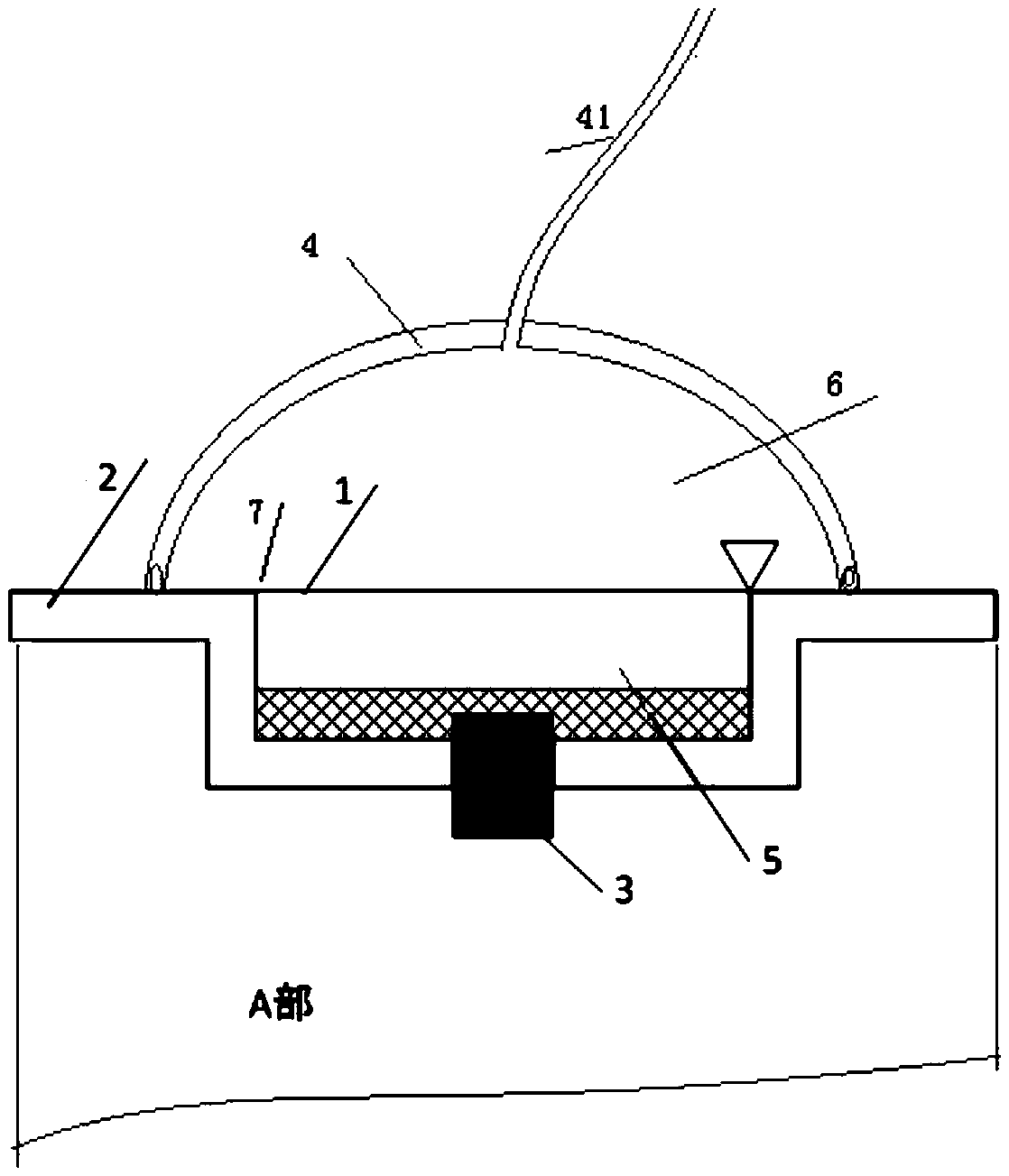

[0063] Step 1: Use a sealing cover (that is, a sealing cover for suppressing helium gas) to seal the sealing welding part to generate a sealed cavity;

[0064] Step 2: Vacuumize the sealed chamber for 30 seconds;

[0065] Step 3: Fill the sealed cavity with helium and pressurize it, wherein the helium injection pressure is 0.5 (Mpa), and the pressure maintenance time is 10 minutes;

[0066] Step 4: Break out the helium gas, and after the helium gas is suppressed, disassemble and remove the sealing cover;

[0067] Helium detection stage:

[0068] Step 5: Place the product in the testing station, and use the isolation cover head (that is, the isolation cover for testing) to seal the sealing welding part to form a sealed cavity;

[0069] Step 6: Detect the leak rate of the sealed cavity with a large and medium leak rate detection instrument, and detect whether the seal b...

Embodiment 2

[0074] For products that have already ruled out large leaks, the following methods can also be used:

[0075] Pressurized helium stage:

[0076] Step 1: Use a sealing cover (that is, a sealing cover for suppressing helium gas) to seal the sealing welding part to generate a sealed cavity;

[0077] Step 2: Vacuumize the sealed chamber for 30 seconds;

[0078] Step 3: Fill the sealed cavity with helium and pressurize it, wherein the helium injection pressure is 0.5 (Mpa), and the pressure maintenance time is 10 minutes;

[0079] Step 4: Break out the helium gas, and after the helium gas is suppressed, disassemble and remove the sealing cover;

[0080] Helium detection stage:

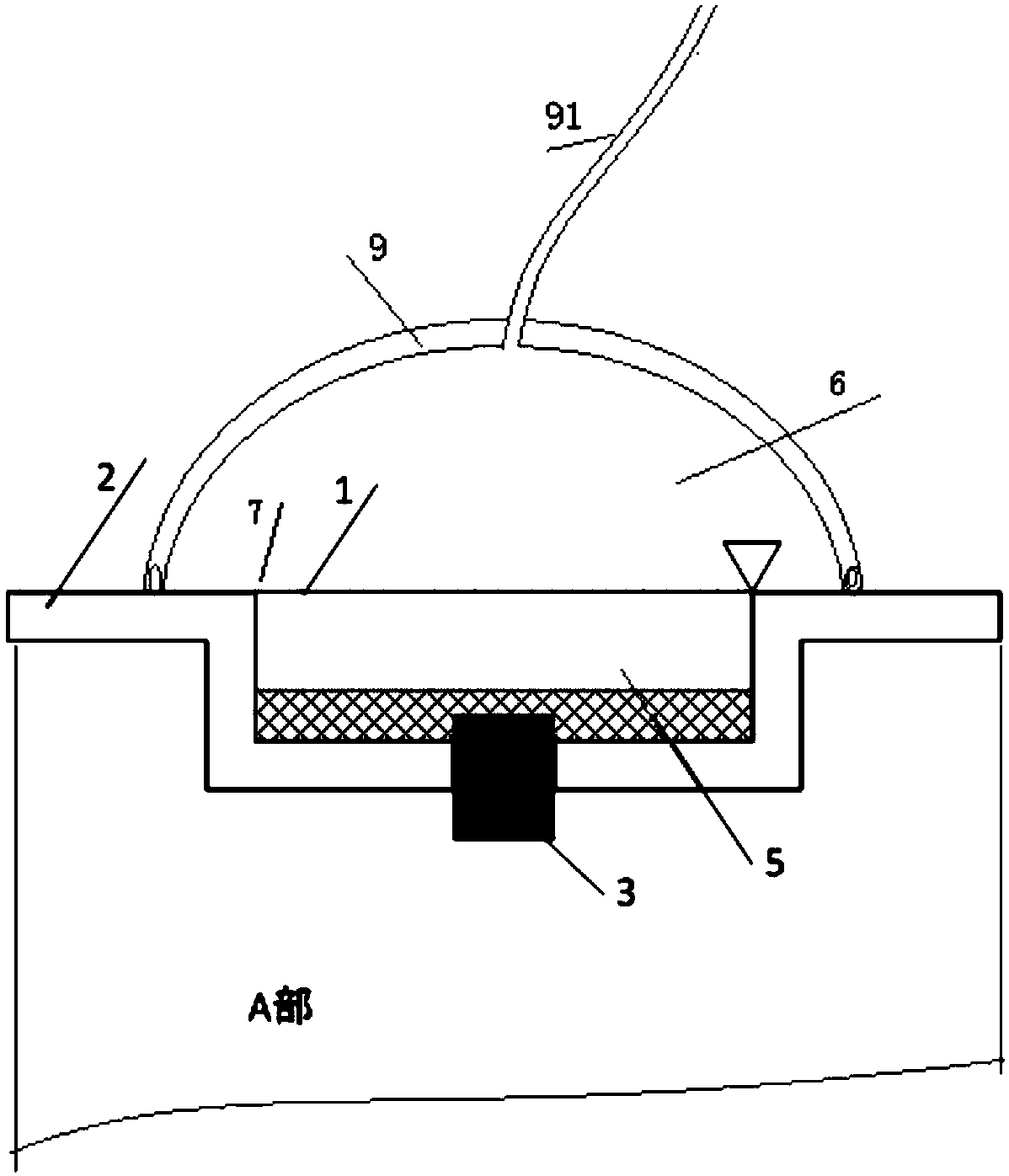

[0081] Step 5: Place the product in the testing station, and use the isolation cover head (that is, the isolation cover for testing) to seal the sealing welding part to form a sealed cavity;

[0082] Step 6: vacuumize the sealed cavity for 30 seconds; then, perform helium mass spectrometry detection (he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com