Laminated structure of stack component and manufacturing method thereof, and the stack component

A technology of laminated structure and laminated assembly, which is applied in coatings, electrical components, semiconductor devices, etc., can solve the problems of heavy packaging materials, cumbersome lamination process, poor lamination effect, etc., to achieve weight reduction and improvement. Aesthetics, the effect of reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

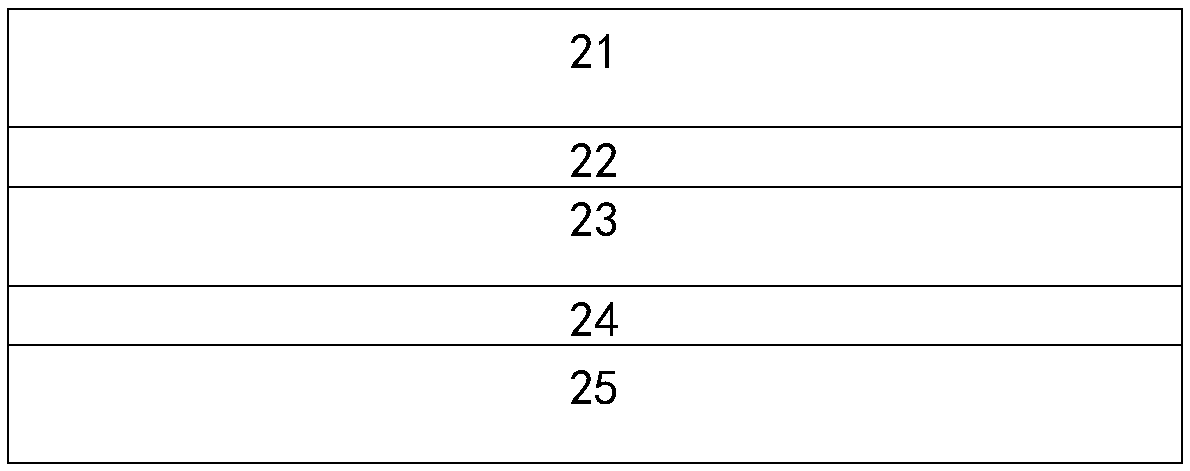

[0058] See figure 2 As shown, a laminated structure of a laminated assembly, the laminated structure includes a first packaging layer 11a, a laminated battery 13a and a second packaging layer 14a, wherein, in order to further enhance the weather resistance, the laminated structure includes a fluoroplastic film layer , the fluoroplastic film layer is located above the first encapsulation layer.

[0059] The laminated structure in this embodiment further includes a first encapsulation film layer 12a, and the first encapsulation film layer 12a is located between the first encapsulation layer 11a and the laminated battery 13a. The first packaging film layer 12a is made of EVA material.

[0060]The first packaging layer is prepared from 30 parts by weight fiber cloth and 70 parts by weight of the first packaging powder coating, and the second packaging layer is prepared from 50 parts by weight fiber cloth and 50 parts by weight of the second packaging powder coating; the fiber cl...

Embodiment 2

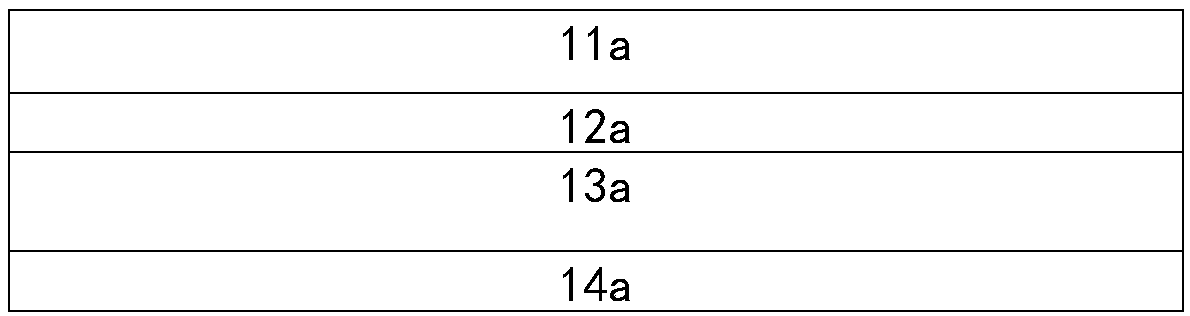

[0078] See image 3 As shown, in this embodiment 2, the laminated structure includes a fluoroplastic film layer 11b, a first packaging layer 12b, a first packaging adhesive film layer 13b, a laminated battery 14b and a second packaging layer 15b, and the fluoroplastic film layer 11b Located above the first encapsulation layer 12b, the rest of the technical solution of this embodiment 2 is the same as that of the above-mentioned embodiment 1.

Embodiment 3

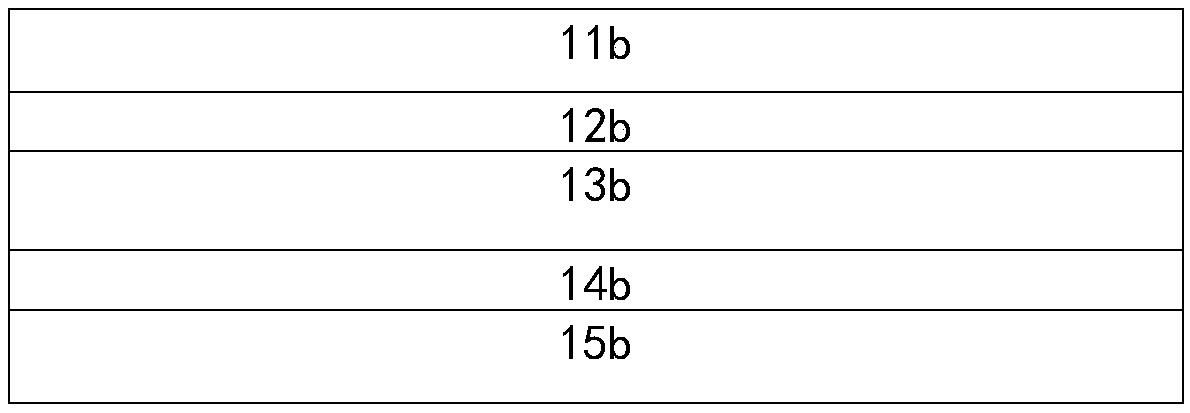

[0080] See Figure 4 As shown, in this embodiment 3, the laminated structure includes the first encapsulation layer 11c, the first encapsulation film layer 12c, the laminated battery 13c, the second encapsulation layer 14c and the back sheet layer 15c, and the back sheet layer 15c is located on the second Below the encapsulation layer 14c, other technical solutions of the third embodiment are the same as those of the first embodiment above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com