Light-reinforcing single-sided light emitting type CSP LED and processing method thereof

A single-sided light-emitting, processing method technology, applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as high light efficiency, low light loss, and difficult lens design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the drawings.

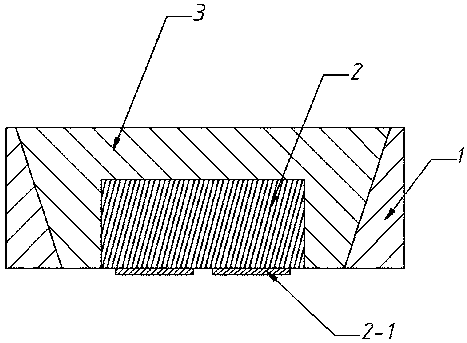

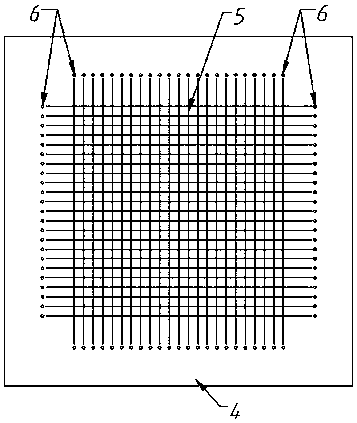

[0037] See as figure 1 As shown, the light-enhancing single-side light-emitting CSP LED described in this specific embodiment is characterized in that it includes a white wall glue 1, an LED chip 2, a packaging glue 3; the white wall glue 1 is in the shape of a bowl , The bottom of which is hollowed out, the LED chip 2 is arranged inside the white wall glue 1, and the electrode surface 2-1 at the bottom of the LED chip 2 is flush with the bottom of the white wall glue 1, and the periphery of the LED chip 2 and the white wall glue The bowl of 1 is filled with encapsulating gel 3.

[0038] Further, the packaging glue 3 is a mixture of phosphor powder and packaging glue.

[0039] Further, the white wall glue 1 is a square bowl-shaped white wall glue, the outer size of which is the size of the CSP LED, and the material is epoxy glue or silicone glue.

[0040] The processing method of the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com