Device and method for improving the performance of an antilock braking and Anti-slip regulation of a vehicle

An anti-lock braking, vehicle technology, applied in the direction of brake components, brakes, brake types, etc., can solve problems such as tire wear, data errors, and impossible to accurately detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

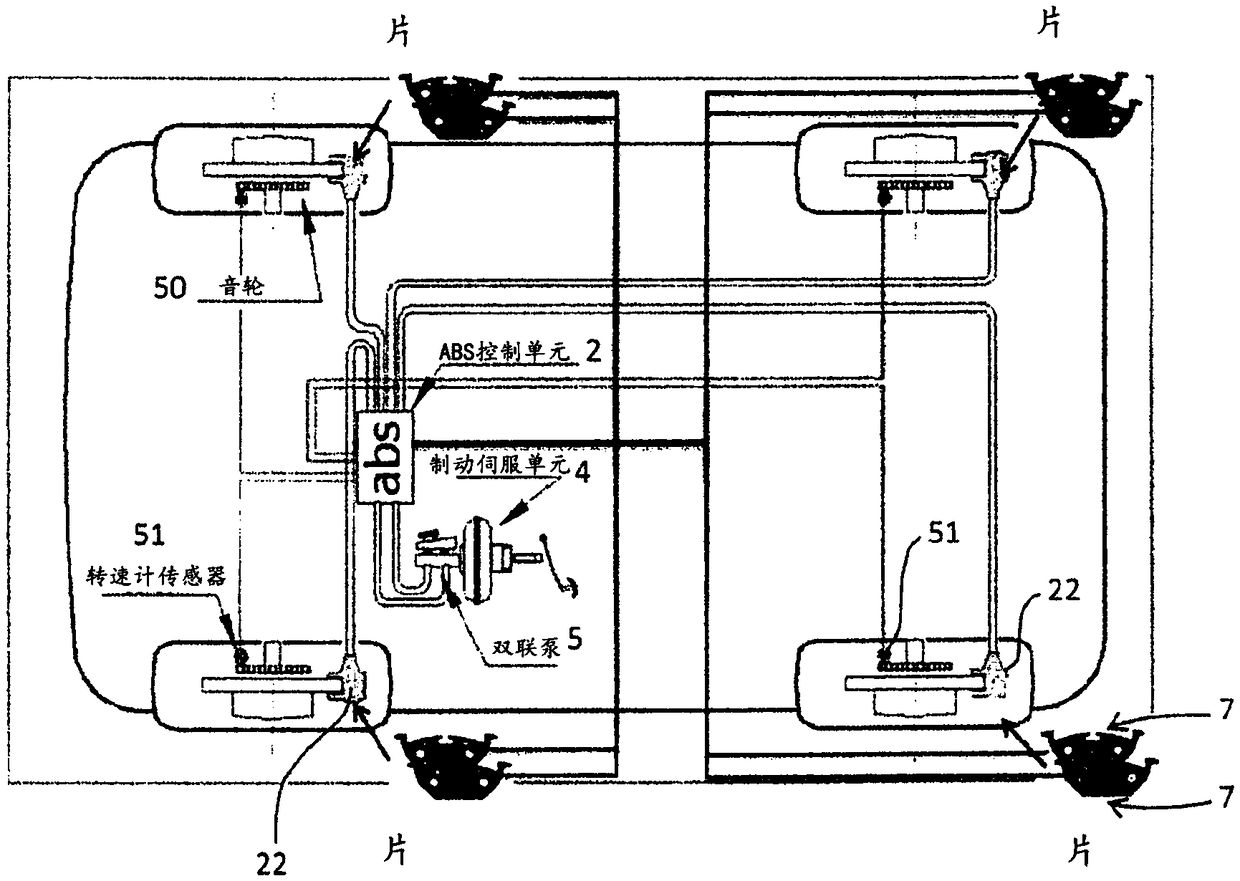

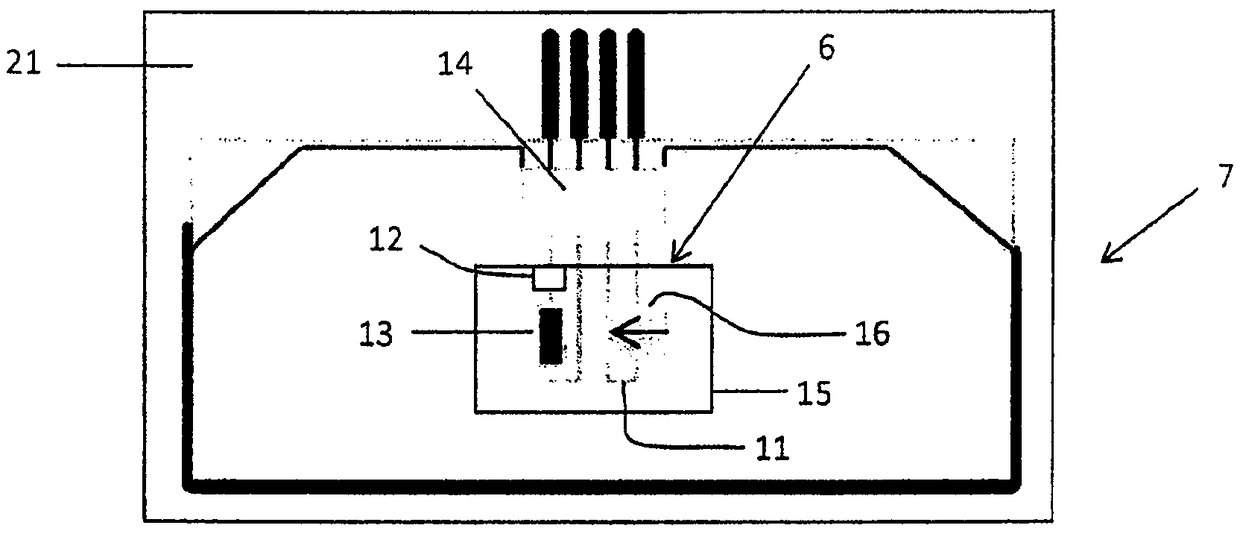

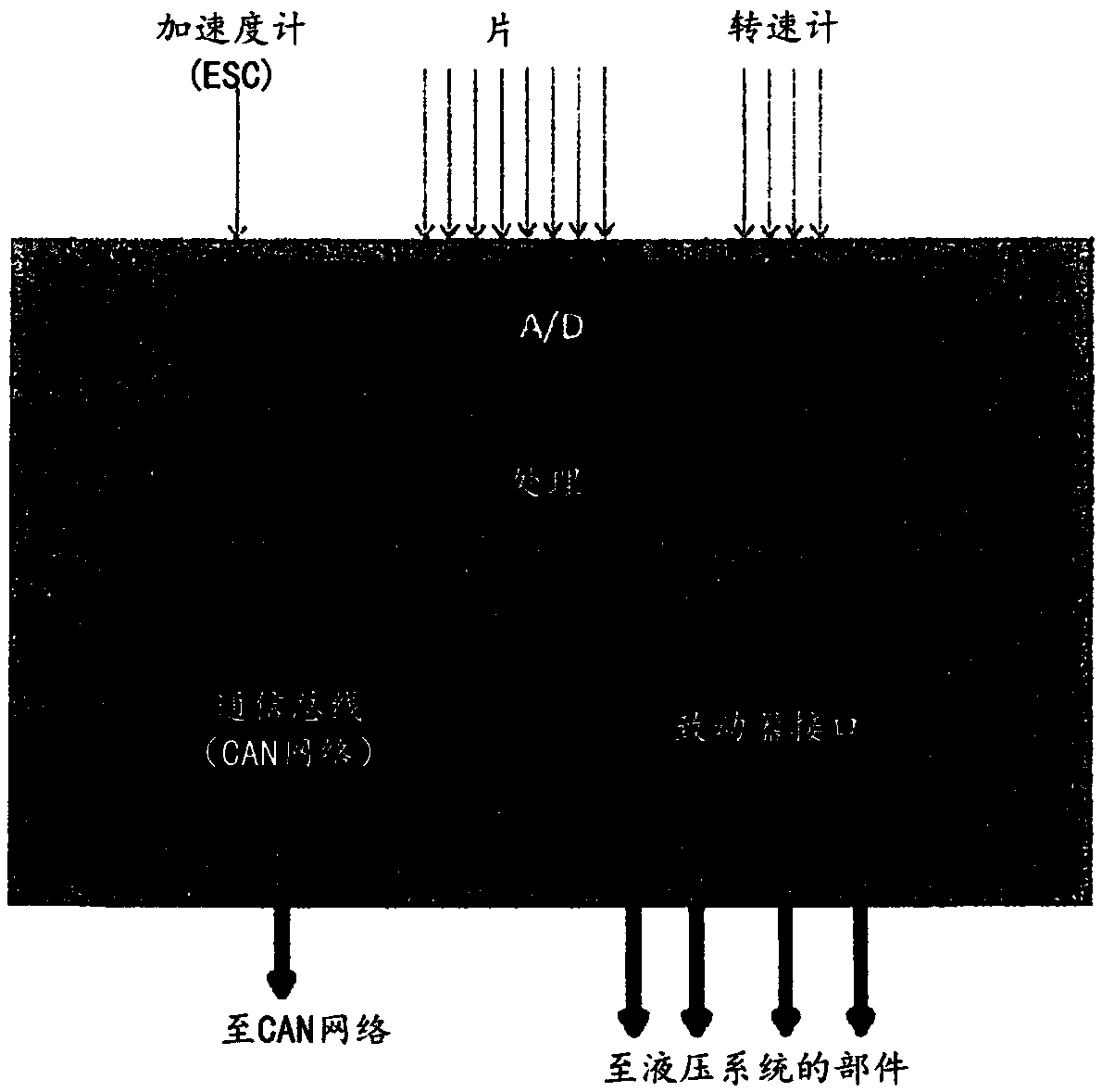

[0042] With reference to the cited figures, an apparatus and method for improving the performance of an anti-lock braking (ABS) and anti-skid regulation (ASR) system of a vehicle includes at least an oil or air hydrodynamic system for controlling brake pressure, the The oil or air fluid power system consists at least of an ABS management control unit denoted 2 and possibly an ASR management control unit 3 , a brake servo unit 4 and a hydraulic oil or air pressure pump 5 . The brake system usually also includes solenoid valves and lines for oil or air and at least a tone wheel 50 and a tachometer sensor 51 , one for each wheel 9 in vehicles equipped with ABS.

[0043] In the following, application of the invention to ABS systems will be considered on the premise that the same characteristics and claims apply also to ABS / ASR systems.

[0044] Furthermore, in the following, reference will be made to motor vehicles equipped with disc brakes, but this applies to any type of vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com