Preparation method and application of humic acid/attapulgite magnetic composite material

A technology of magnetic composite materials and attapulgite, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problems of poor adsorption effect of propranolol, low recovery efficiency and regeneration efficiency, and achieve low price, The effect of small iron loss and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The specific embodiment of the present invention provides a preparation method of humic acid / attapulgite magnetic composite material, the preparation method includes the following steps:

[0041] Step 1: Activate the original attapulgite soil with strong acid to remove the cemented carbonate and adsorbed cations on the original attapulgite soil; after activation, wash to neutrality, dry and grind to obtain acid-modified unevenness Stick soil, spare;

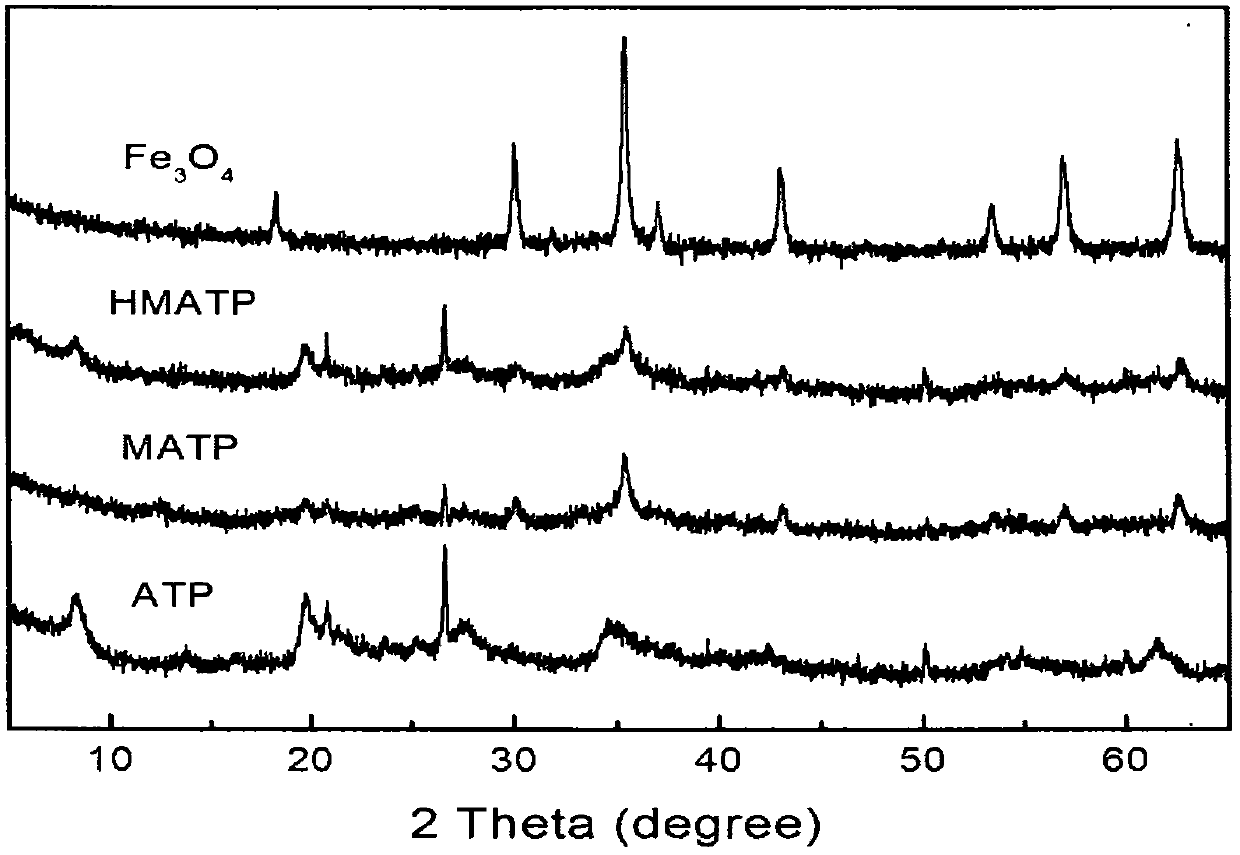

[0042] Step 2: Take the acid-modified attapulgite prepared in step 1, and load ferroferric oxide on the surface of the acid-modified attapulgite, and then ultrasonically disperse the acid-modified attapulgite (ATP) on the surface Obtain attapulgite suspension in deionized water;

[0043] Continue to add ferrous sulfate heptahydrate to the attapulgite suspension to obtain the first mixed solution; place the prepared first mixed solution in a water bath at 90°C for preheating;

[0044] Step 3: Combine NaOH and NaNO 3 After mixing, ...

Embodiment 1

[0055] This embodiment provides a method for preparing a humic acid / attapulgite magnetic composite material, including the following steps:

[0056] Step 1: The original attapulgite soil was first activated with 5% hydrochloric acid for 48 hours, washed to neutrality, dried at 110°C, ground through a 200-mesh sieve, and set aside.

[0057] Step 2: Take acid-modified attapulgite, and load ferroferric oxide on the surface of acid-modified attapulgite. First take 1g of acid-modified attapulgite and disperse it in 200ml of deionized water by ultrasonic for 30min, and then add 4g of ferrous sulfate heptahydrate to the attapulgite suspension to obtain the first mixed solution; Put the liquid in a water bath at 90℃ for heat preservation;

[0058] Step 3: Take another 3.6g NaOH and 1.8g NaNO 3 Dissolve it in 80ml of aqueous solution and add 0g of humic acid to obtain a second mixed solution, which is also placed in a water bath at 90°C for heat preservation;

[0059] Step 4: In N 2 In the ca...

Embodiment 2

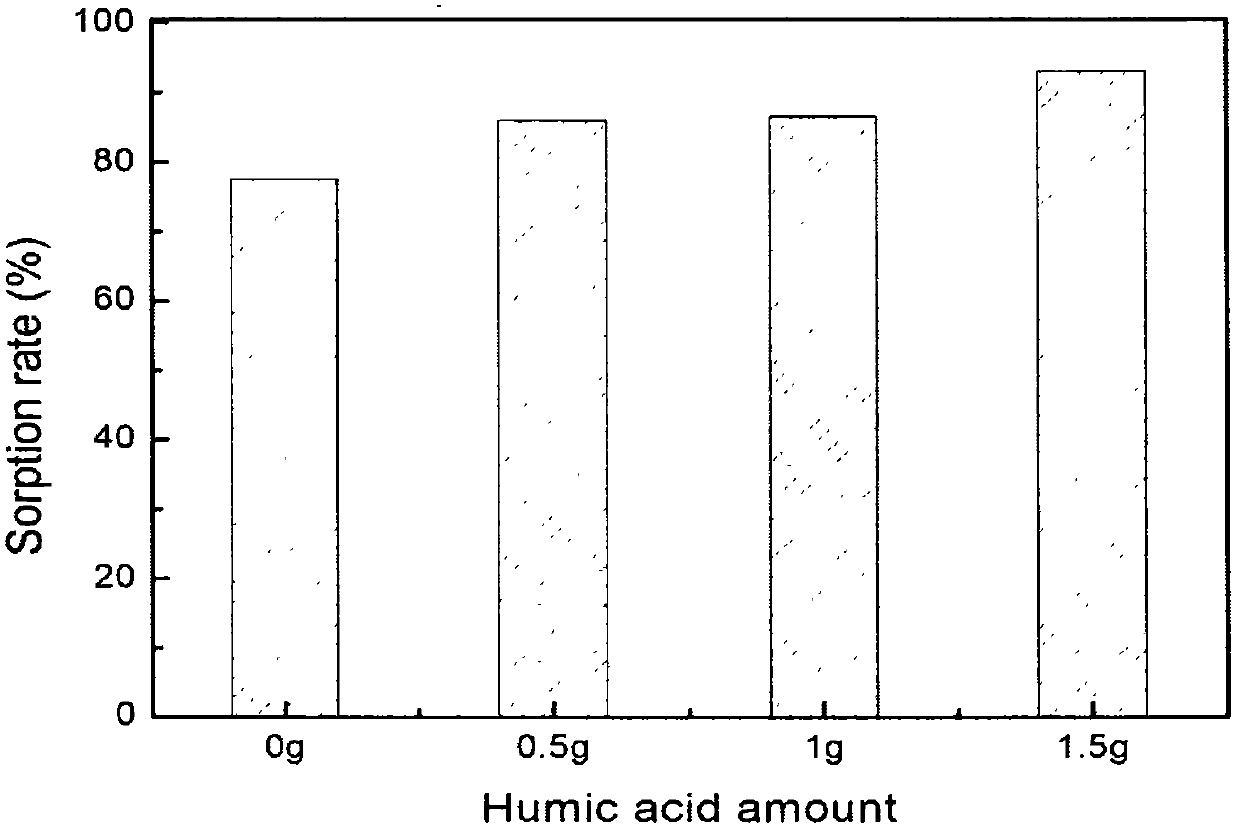

[0062] This embodiment provides a method for preparing a humic acid / attapulgite magnetic composite material: 0.5 g of humic acid is added in step three, and the other method steps are the same as those in embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com