Waterproof treatment process for hardware product

A technology for waterproof treatment and products, applied in electrical components, electrical equipment casings/cabinets/drawers, special surfaces, etc., can solve the problem of less design space for electronic waterproofing, and achieve the effect of high-efficiency waterproofing, reducing the number of parts, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

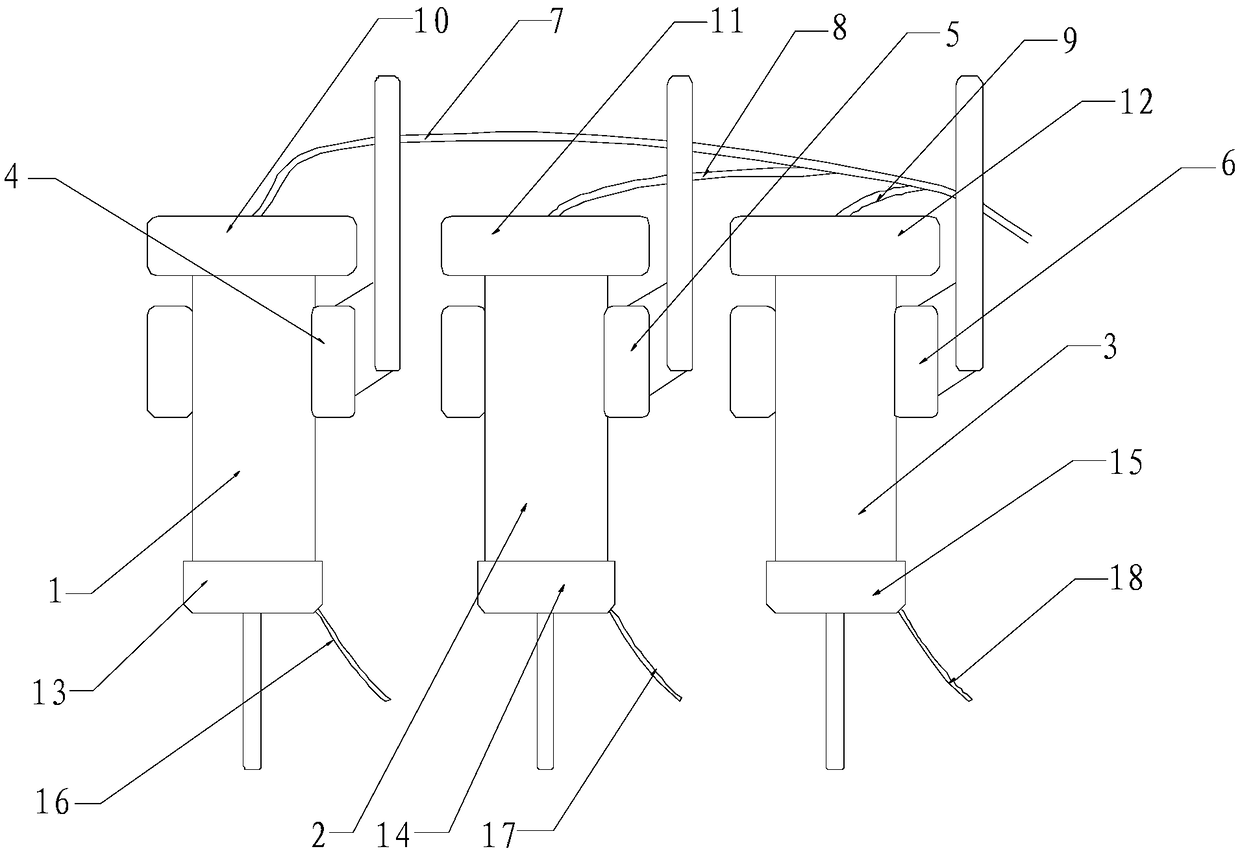

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0030] A waterproof treatment process for hardware products, comprising the following steps: step A, selecting corresponding waterproof coating materials according to different substrates and functions of products; step B, subpackaging corresponding waterproof coating materials into syringes of different dispensing machines Inside; step C, set the dispensing route and glue output of different dispensing machines according to needs; step D, dispensing through the dispensing machine corresponding to the position of different substrates and functions of the product, and quickly place it for automatic leveling. The treatment process of the present invention selects different waterproof coating materials according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com