Sand and powder separation system

A separation system, sand powder technology, applied in the direction of solid separation, separation of solids from solids with air flow, chemical instruments and methods, etc., can solve the problem of insufficient concentration, insufficient air velocity, insufficient separation of coarse sand and sand powder, etc. problems, to achieve the effect of novel structure, stable quality and less stone powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

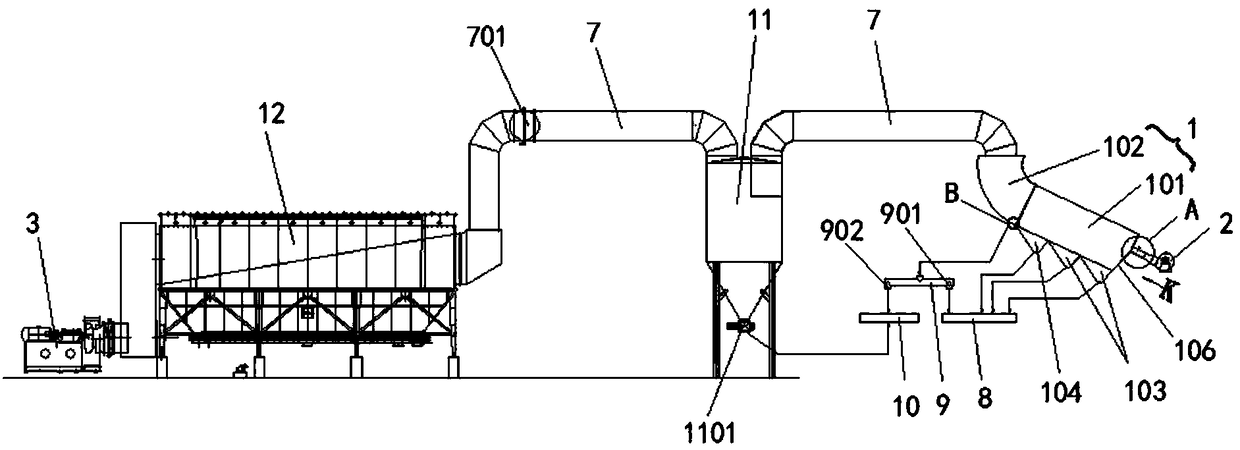

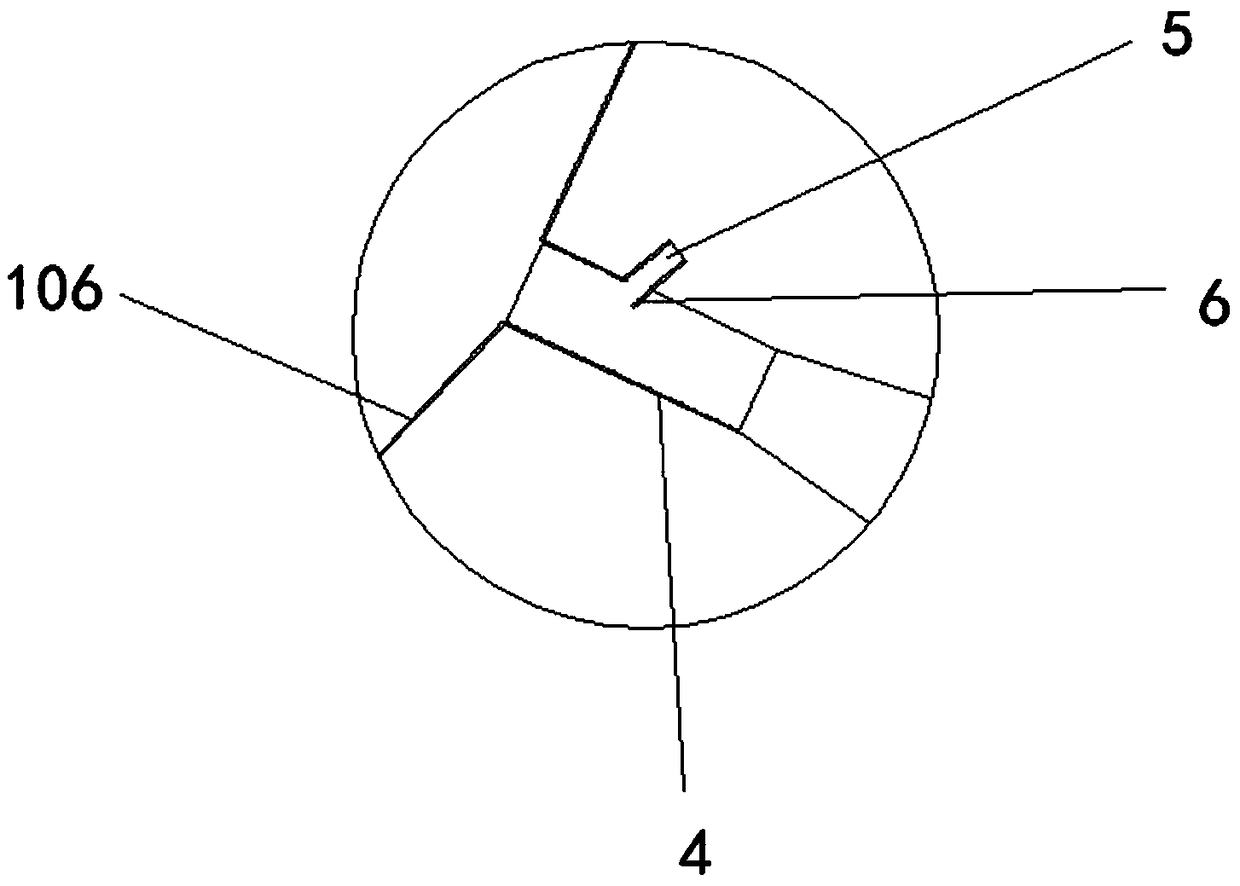

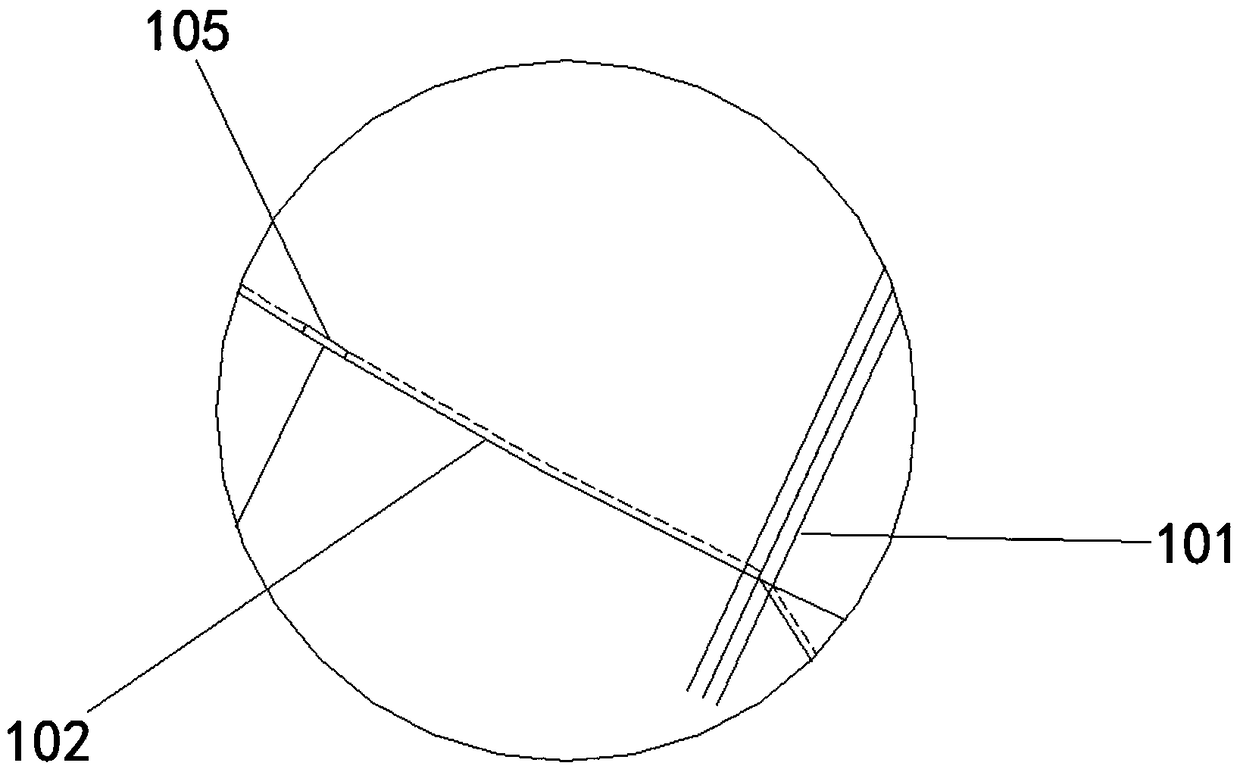

[0025] like Figure 1-Figure 4 As shown, the embodiment of the present invention provides a sand powder separation system, including a sand powder separator 1, a blower 2 and an induced draft fan 3. The sand powder separator 1 is formed by splicing a rectangular box 101 and an arc box 102. The tail end of the rectangular box 101 is connected to the air outlet of the blower 3 through an air inlet and drainage pipe 4, and the organic sand inlet 5 is arranged on the air inlet and drainage pipe 4, and the machine sand inlet 5 is close to the side of the blower 2 A wind blocking plate 6 is provided; the bottom of the rectangular box 101 is provided with a coarse sand discharge port 103 and a medium sand discharge port 104; The bottom of the rectangular box 102 is provided with a first fine sand outlet 105 near the position of the rectangular box 101; in the installed state, the sand powder separator 1 is inclined, and the outlet of the arc box 102 is vertically upward.

[0026] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com