Device for thin-walled tank puncturing

A tank and puncture technology, applied in the field of mechanical equipment, can solve problems such as low effectiveness and high safety hazards, and achieve the effects of avoiding corrosion, improving work efficiency, and being easy to place and take out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

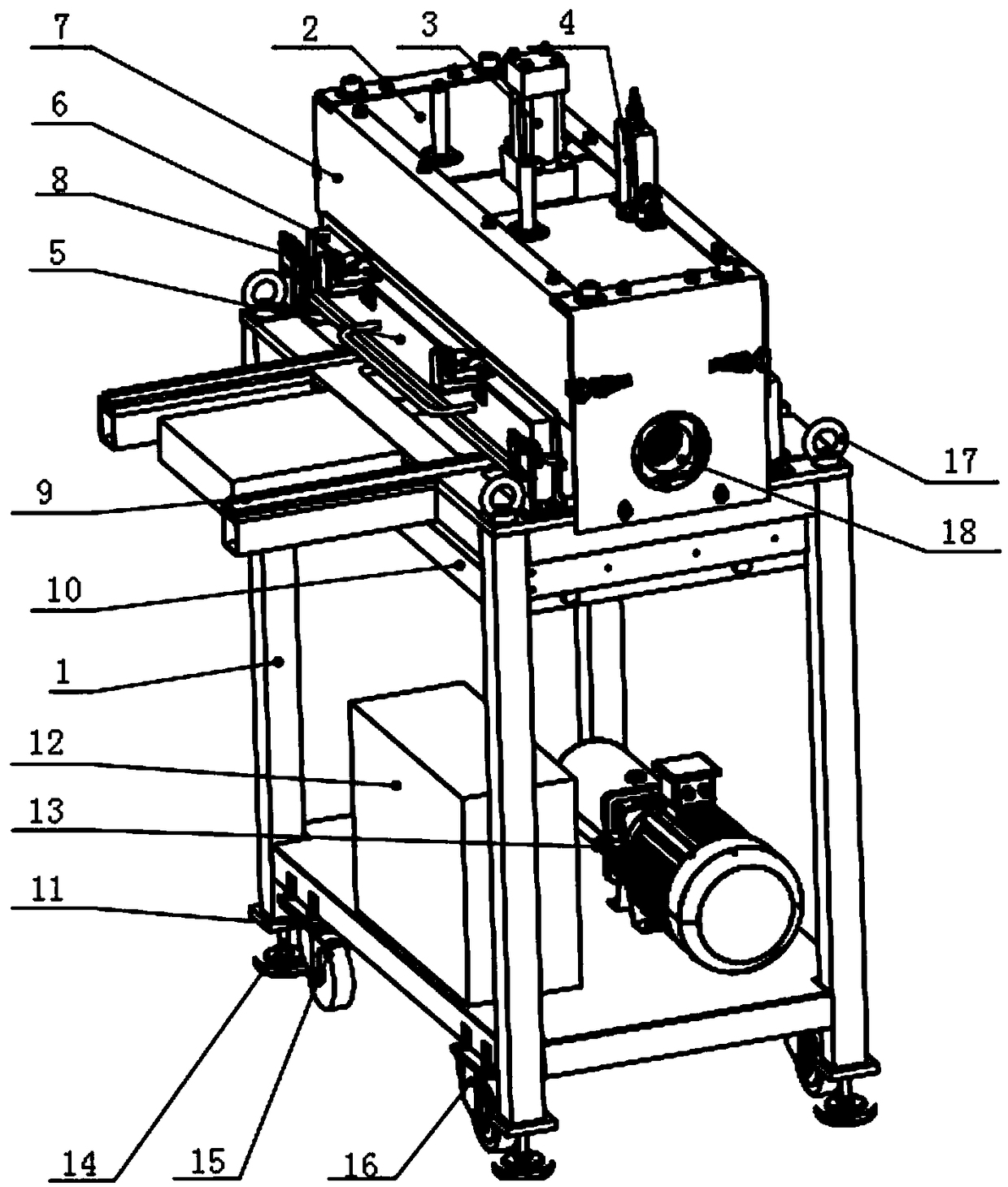

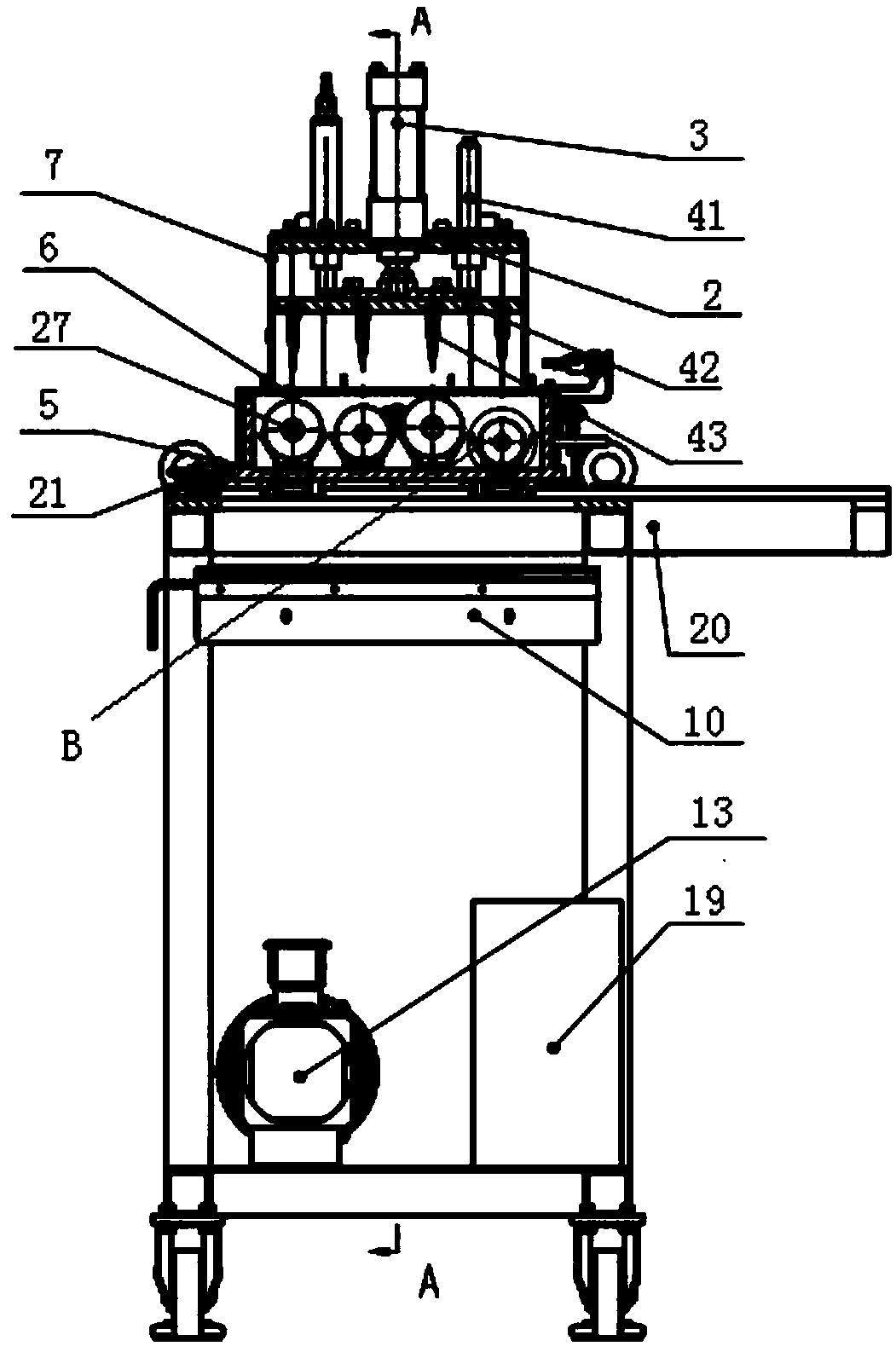

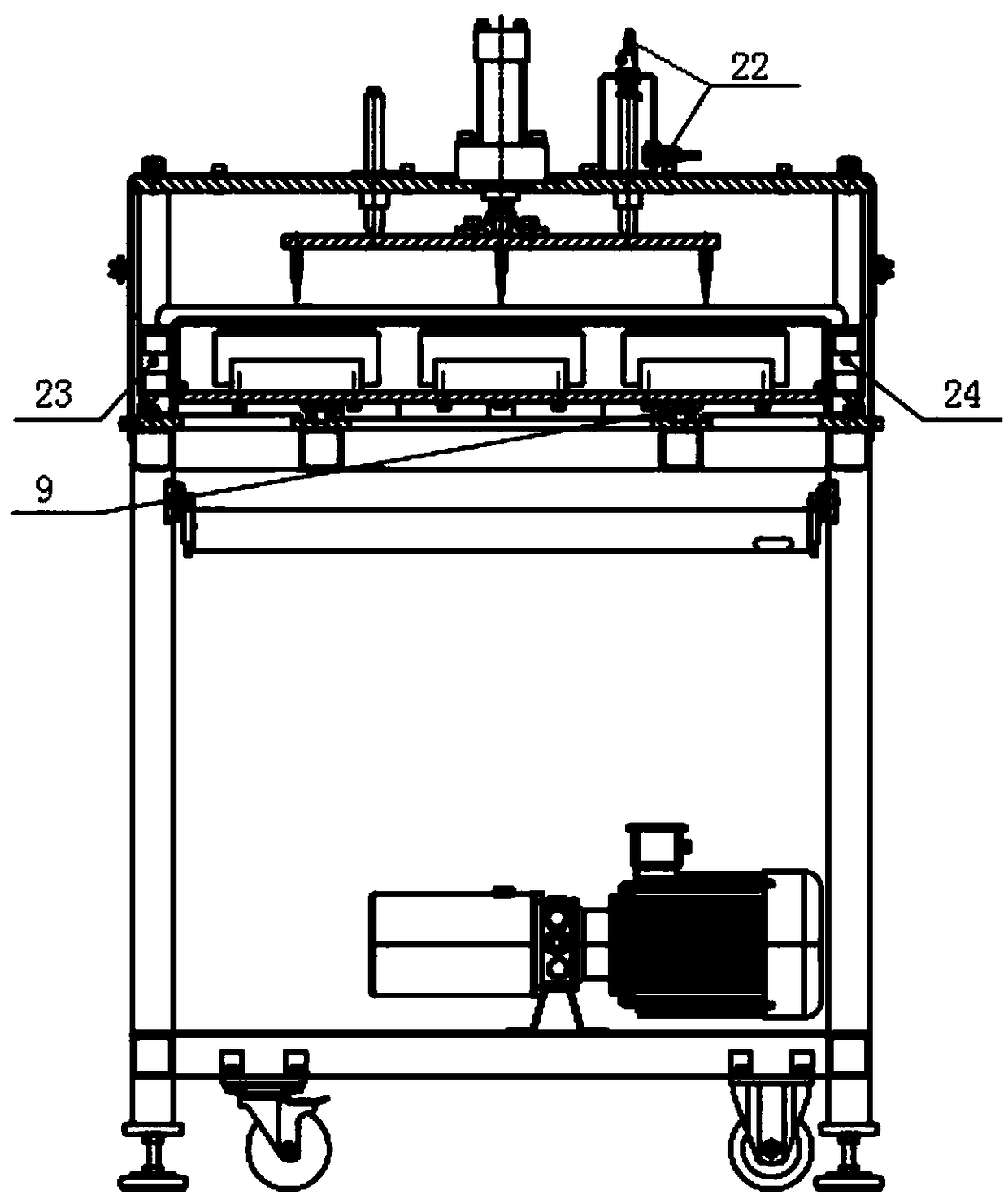

[0030] see Figure 1 to Figure 4 , a device for puncturing thin-walled tanks, including a bottom frame 1, an upper frame 2, a linear guide rail 9, a drawer body 5, an inner shield 6, an outer shield 7, a hydraulic cylinder 3, an actuator 4, a mechanical Locking structure 8 , supporting structure 11 , liquid accumulation tray 10 , hydraulic pump station 13 , and control system 12 . The chassis 1 is assembled and welded by rectangular profiles and plates, which has sufficient strength and rigidity. The upper frame 2 includes four columns and a top plate, and the four columns are evenly arranged under the top plate; the hydraulic cylinder 3 is located above the upper frame 2, and the actuator 4 is located below the upper frame 2, and the actuator includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com