Power outage self-protection method of industrial robot and industrial robot achieving power outage self-protection method

An industrial robot and electricity storage technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of damage to the robot arm, impact of the robot arm, and high motor costs, and achieve the effect of saving device costs, reducing costs, and simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

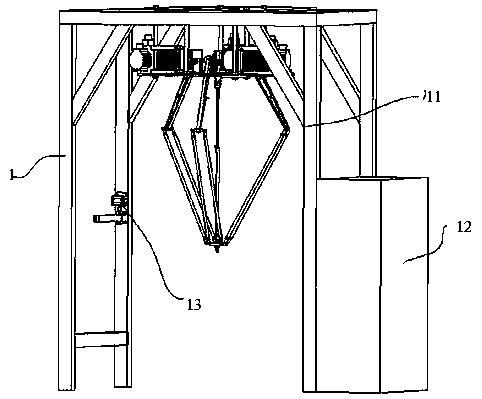

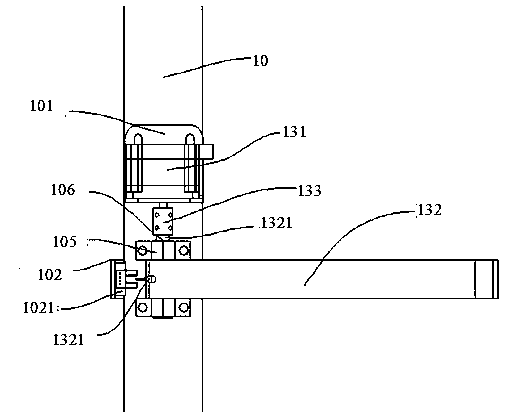

[0025] see figure 1 , the delta robot of the present invention includes a support 1, and a machine body 11 located on the support, an electrical cabinet 12 and a parking mechanism 13, and the machine body 11 includes three parallel servo shafts, servo motors and mechanical arms.

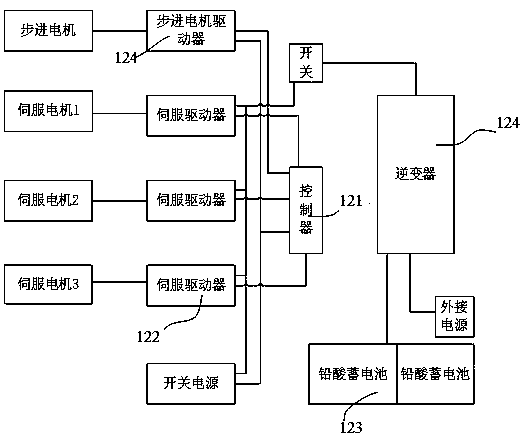

[0026] image 3 It is the control circuit diagram of the delta sorting robot of the present invention. It is located in the electrical cabinet 12 , and it can be seen that the electrical cabinet 12 is provided with a multi-axis linkage controller 121 , a servo motor driver 122 , a lead-acid battery 123 and an inverter 124 . The multi-axis linkage controller of the present invention is composed of a micro control unit (MCU), a drive module, a communication module, and a storage module. According to a preset program, it sends a pulse signal to the servo driver 122, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com