Method for preparing nano magnesium hydroxide through mechanical ball milling

A technology of nano-magnesium hydroxide and mechanical ball milling, applied in the direction of magnesium hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of increased difficulty and cost of production, and achieve low cost, high purity, and favorable large-scale industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Step S1: Put 2g of magnesium oxide powder in the ball mill jar of the planetary ball mill, add 20g of deionized water at room temperature and 84g of grinding balls;

[0018] Step S2: Use a planetary ball mill to mill at a speed of 240r / min for 1 hour, then mill at a speed of 360r / min for 1 hour, and add 2g of deionized water at room temperature every 30 minutes during the milling;

[0019] Step S3: taking out the slurry obtained after ball milling and vacuum drying at 120° C. until the sample has constant weight to obtain nano-sized magnesium hydroxide;

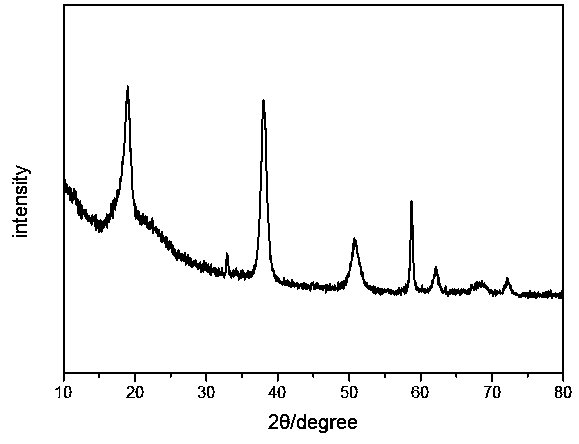

[0020] figure 1 It is the XRD pattern of the nano-magnesium hydroxide that the present embodiment makes, compares the standard XRD pattern of magnesium hydroxide, the magnesium hydroxide that the present embodiment makes is completely consistent with the standard XRD pattern peak position of magnesium hydroxide, in the XRD pattern There were no other peaks in , indicating that the product was of high purity. , so it ...

Embodiment 2

[0023] Step S1: Put 2g of magnesium oxide powder in the ball mill jar of the planetary ball mill, add 16g of deionized water at room temperature and 84g of grinding balls;

[0024] Step S2: Use a planetary ball mill to mill at a speed of 240r / min for 1 hour, then mill at a speed of 360r / min for 1 hour, and add 4g of deionized water at room temperature every 30 minutes during the milling;

[0025] Step S3: Take out the slurry obtained after ball milling and vacuum-dry at 120° C. until the sample has a constant weight to obtain nano-magnesium hydroxide.

Embodiment 3

[0027] Step S1: Put 2g of magnesium oxide powder in the ball mill jar of the planetary ball mill, add 24g of deionized water at room temperature and 84g of grinding balls;

[0028] Step S2: use a planetary ball mill to mill at a speed of 240r / min for 1 hour, then mill at a speed of 360r / min for 1 hour, and add 3g of deionized water at room temperature every 30 minutes during the milling;

[0029] Step S3: Take out the slurry obtained after ball milling and vacuum-dry at 120° C. until the sample has a constant weight to obtain nano-magnesium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com