Field manual correction device and correction method for continuous annealing furnace

A technology of continuous annealing furnace and deviation correction device, which is applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of high-efficiency production inconvenience, inability to meet the production needs of large-scale continuous annealing furnaces, and large nitrogen consumption, so as to shorten the time for handling accidents , to avoid the effect of a large amount of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

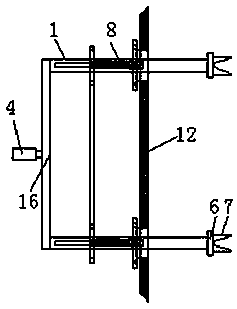

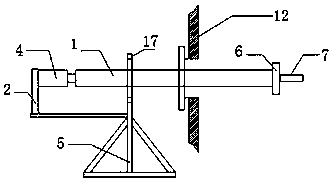

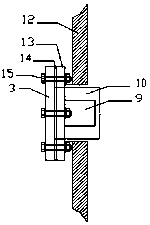

[0026] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

[0027] Refer to attached figure 1 , 2 , an on-site manual deviation correction device for continuous annealing furnaces, comprising a transmission rod 1, a jack 4, a bracket 5, a deviation correction disc 6, a strip steel guide plate 7, a scale 8, a connecting plate 16 and a positioning ring 17, two transmission rods arranged in parallel One end of 1 is respectively fixed on the connection plate 16, the jack 4 is driven and connected with the connection plate 16, and the other ends of the two transmission rods 1 arranged in parallel are respectively fixedly connected with a deviation correction disc 6, and the deviation correction disc 6 is provided with a strip steel The guide plate 7, the strip steel guide plate 7 is provided with a V-shaped groove, the transmission rod 1 is provided with a scale 8, and the transmission rod 1 is fixed on the support 5 throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com