A driving device for powder ion plasma coating equipment

A technology of plasma plasma and driving device, which is applied in the direction of coating, molten spraying, metal material coating process, etc., can solve the problems of inability to cool the product, and the heat dissipation and sound insulation effect of the spraying driving device is not obvious, so as to shorten the service life, The effect of improving the safety of use and reducing the transmission of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

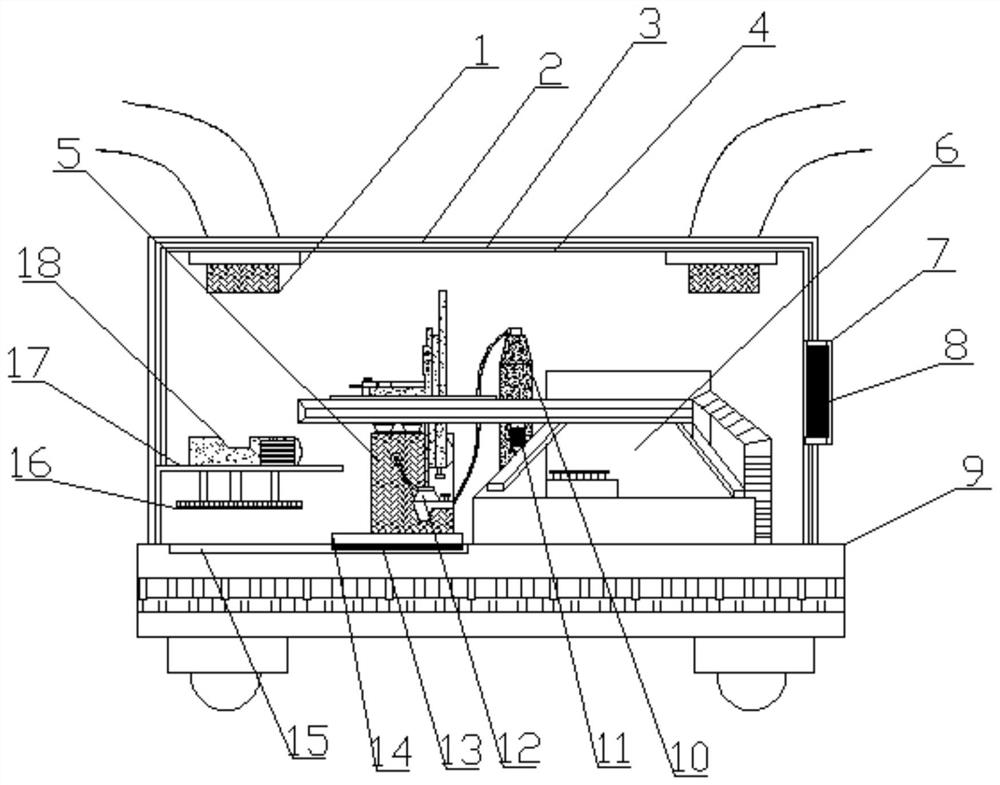

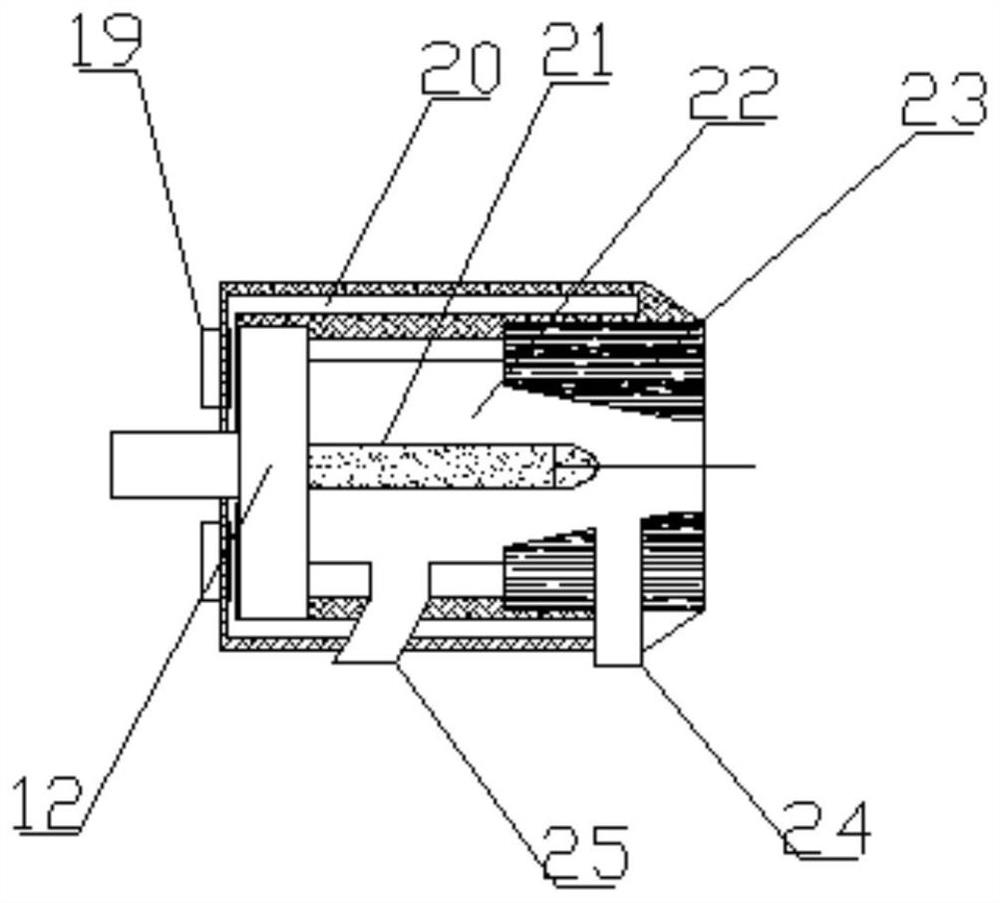

[0023] like Figure 1-2 As shown, a driving device for powder ion plasma coating equipment includes a base 9, an outer shell 2 and a plasma spray gun 12, the top of the base 9 is equipped with an outer shell 2 by bolts, and one part of the outer shell 2 An air inlet 7 is provided on the side, and a cooling fan 8 is installed through screws in the air inlet 7, a sound insulation layer 4 is provided on the inner surface of the outer casing 2, and a heat insulation layer 3 is arranged between the sound insulation layer 4 and the outer casing 2 , the two ends of the inner top of the outer shell 2 are installed with exhaust fans 1 through screws, the inner bottom of the outer shell 2 is equipped with a manipulator body 6 through a mounting plate, and the output end of the manipulator body 6 is equipped with a plasma spray gun 12 through bolts, so One end of the inner bottom of the outer casing 2 is provided with an electric slide rail 15, and the upper end of the electric slide rai...

Embodiment 2

[0037] like Figure 1-2 As shown, a driving device for powder ion plasma coating equipment includes a base 9, an outer shell 2 and a plasma spray gun 12, the top of the base 9 is equipped with an outer shell 2 by bolts, and one part of the outer shell 2 An air inlet 7 is provided on the side, and a cooling fan 8 is installed through screws in the air inlet 7, a sound insulation layer 4 is provided on the inner surface of the outer casing 2, and a heat insulation layer 3 is arranged between the sound insulation layer 4 and the outer casing 2 , the two ends of the inner top of the outer shell 2 are installed with exhaust fans 1 through screws, the inner bottom of the outer shell 2 is equipped with a manipulator body 6 through a mounting plate, and the output end of the manipulator body 6 is equipped with a plasma spray gun 12 through bolts, so One end of the inner bottom of the outer casing 2 is provided with an electric slide rail 15, and the upper end of the electric slide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com