Drilling-grouting integrated equipment and construction method for road base reinforcement

A technology for road base and equipment, applied in the direction of roads, roads, buildings, etc., can solve the problems of numerous on-site equipment, influence of construction efficiency, complexity, etc., and achieve the effect of being beneficial to management, improving construction efficiency, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

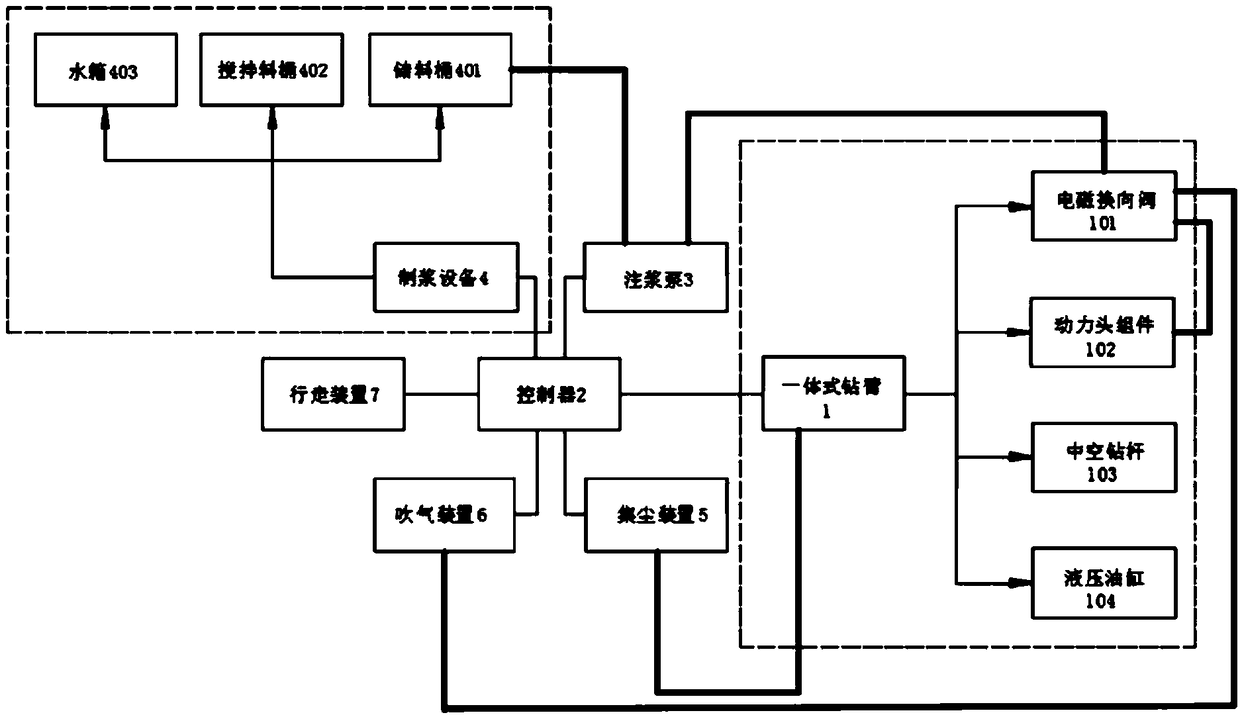

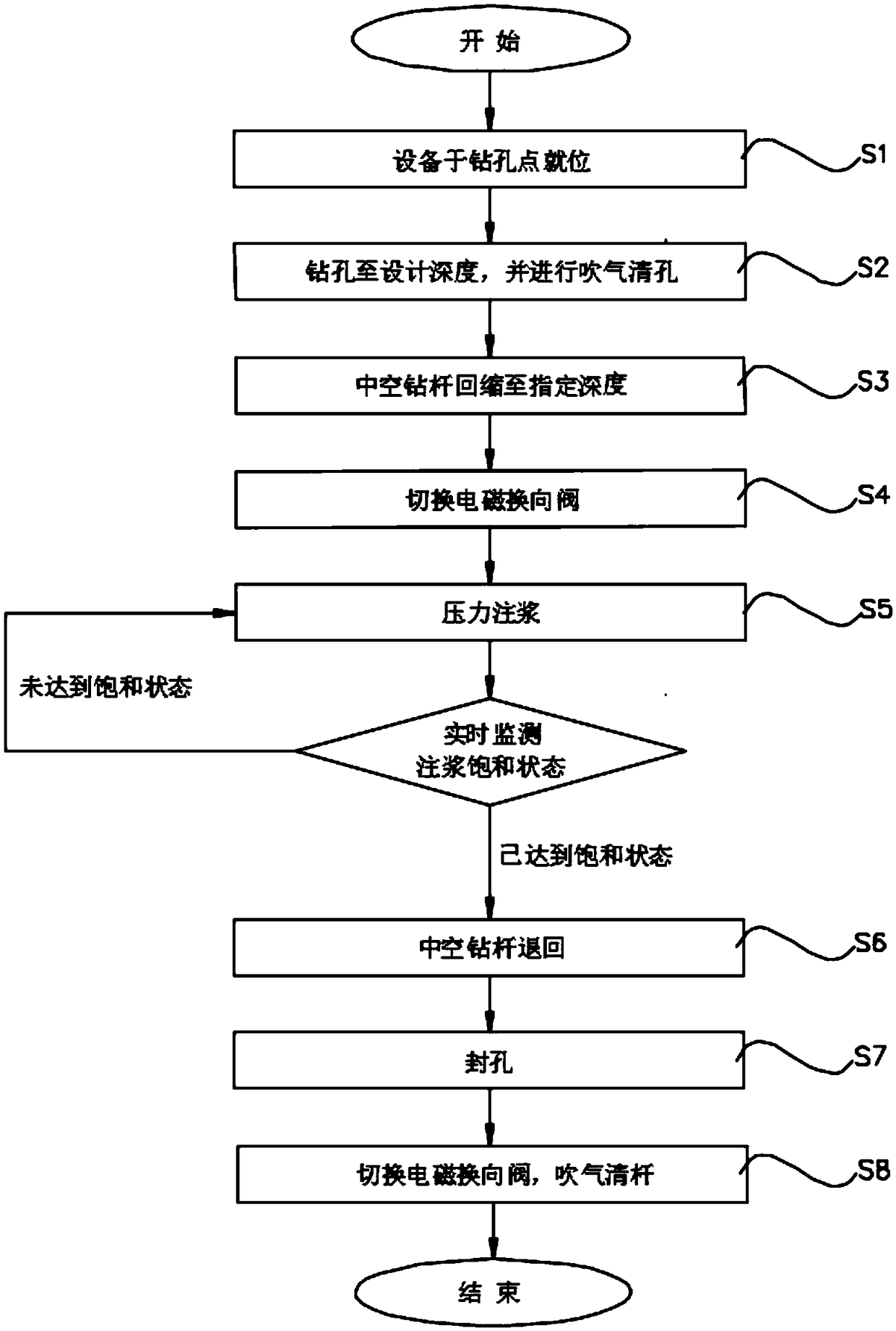

[0036] refer to figure 1 As shown, the integrated drilling and injection equipment for road base reinforcement of the present invention includes an integrated drilling arm 1 , a grouting pump 3 , a slurrying equipment 4 , a dust collecting device 5 , an air blowing device 6 and a traveling device 7 .

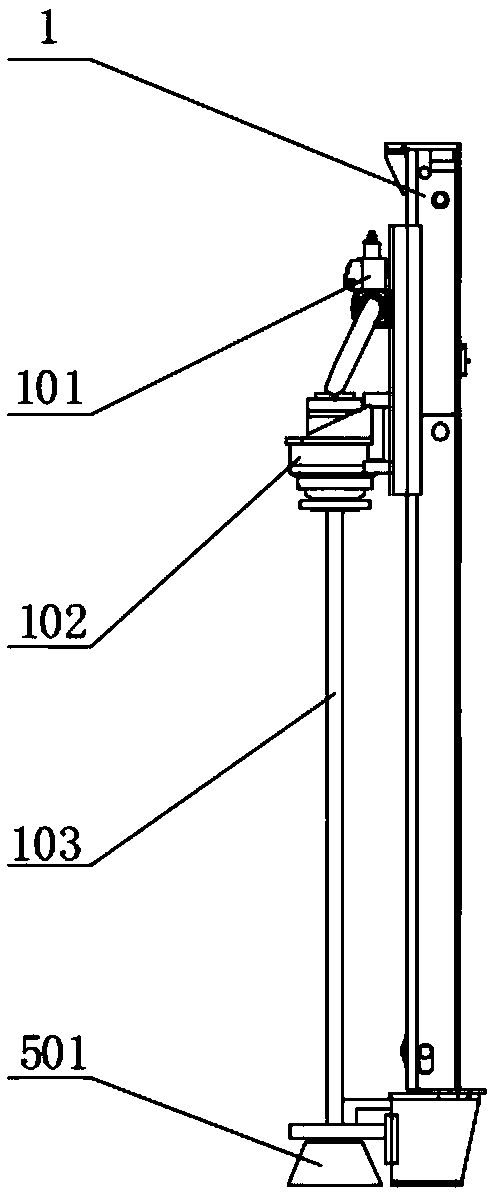

[0037] refer to figure 2 and combine figure 1 As shown, the integrated drill boom 1 includes an electromagnetic reversing valve 101, a power head assembly 102, a hollow drill rod 103, a hydraulic cylinder 104 and a sliding base (not shown in the figure). The electromagnetic reversing valve 101 is located above the power head assembly 102, and both are arranged on the sliding base. In this embodiment, the electromagnetic reversing valve 101 is a two-position three-way valve, of course...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com