Construction method for lifting-type bridge pier scaffold

A scaffolding and lifting technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high hydrological address requirements, poor safety and reliability, waste of materials, etc., to achieve protection measures in place, less equipment investment, and materials low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present invention is realized through the following technical solutions, and the present invention is realized through the following technical solutions: the lifting type bridge pier scaffolding construction method, specifically comprising the following steps:

[0038] Step S1: preparatory work before construction;

[0039] Step S2: installation of main girders and longitudinal beams;

[0040] Step S3: installation of steel pipe scaffolding;

[0041] Step S4: pier body construction;

[0042] Step S5: Construction of upper and lower pedestrian passages;

[0043] Step S6: Scaffold lifting;

[0044] Step S7: Scaffold removal.

[0045] It should be noted that, through the above improvements,

[0046] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

Embodiment 2

[0048] This embodiment is further optimized on the basis of the above embodiments, and the step S1 specifically includes the following steps:

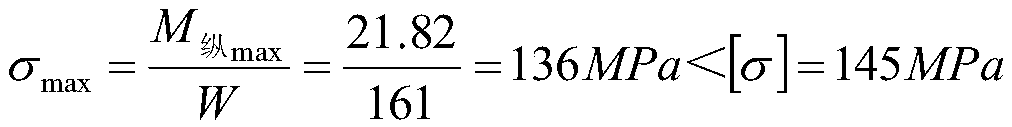

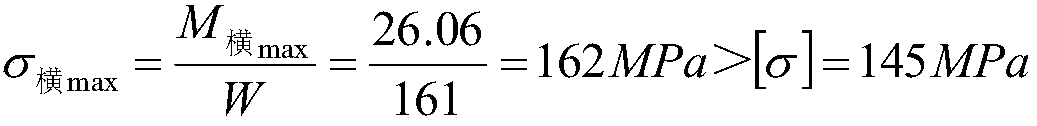

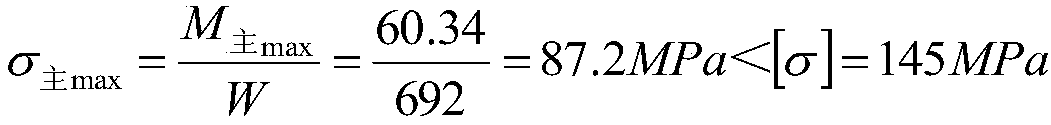

[0049] Step S11: Scaffold design and force check calculation; specifically refers to: load value calculation, scaffold bearing capacity check calculation, longitudinal beam check calculation, beam check calculation, main girder check calculation, steel bar check calculation;

[0050] Load value calculation:

[0051] 1) Dead load

[0052] The pole is made of Φ48 steel pipe with a wall thickness of 3.5mm; the steel pipe’s 3.14*(0.024 2 -0.0225 2 )*7850*10=17.2N / m

[0053] The self-weight of the pole is:

[0054] q 立 =12*(9+3)*2*2*17.2=9.91kN;

[0055] The crossbar has its own weight, and the crossbar has 7 floors.

[0056] The self-weight of the crossbar is:

[0057] q 横 =7*(7.6+1.7)*2*2*17.2=8.81kN;

[0058] 90cm long horizontal short rod self-weight:

[0059] q 横短 =6*0.9*17.2*60=5.57kN;

[0060] Self-weight of connecting r...

Embodiment 3

[0126] This embodiment is further optimized on the basis of the above embodiments. The step S2 specifically means that the top surface of the cap platform that has been constructed is used as the base surface, and the main beam, cross beam and longitudinal beam are installed; specifically, the following steps are included:

[0127] Step S21: the two symmetrical sides of the base surface are connected to the main girder through steel rods; the main girder is installed on the steel rods.

[0128] Step S22: Arranging successively connected beams around the base surface, the main beam is used to support the beams; two beams on the same side are parallel to each other and connected by rebar.

[0129] It should be noted that through the above improvements, during installation, the welding seam between the main beam and the cross beam shall be welded by skilled welders in accordance with the requirements of relevant specifications. The steel bars of Φ25 are connected.

[0130] Other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com