TBM (tunnel boring machine) tunnel application segment temporary support device and pea gravel backfill grouting method

A temporary support, bean gravel technology, applied in tunnels, tunnel linings, shaft equipment and other directions, can solve the problems of reduced project quality, floating segments, insufficient bean gravel backfill, etc., to improve overall safety, ensure construction progress, Simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

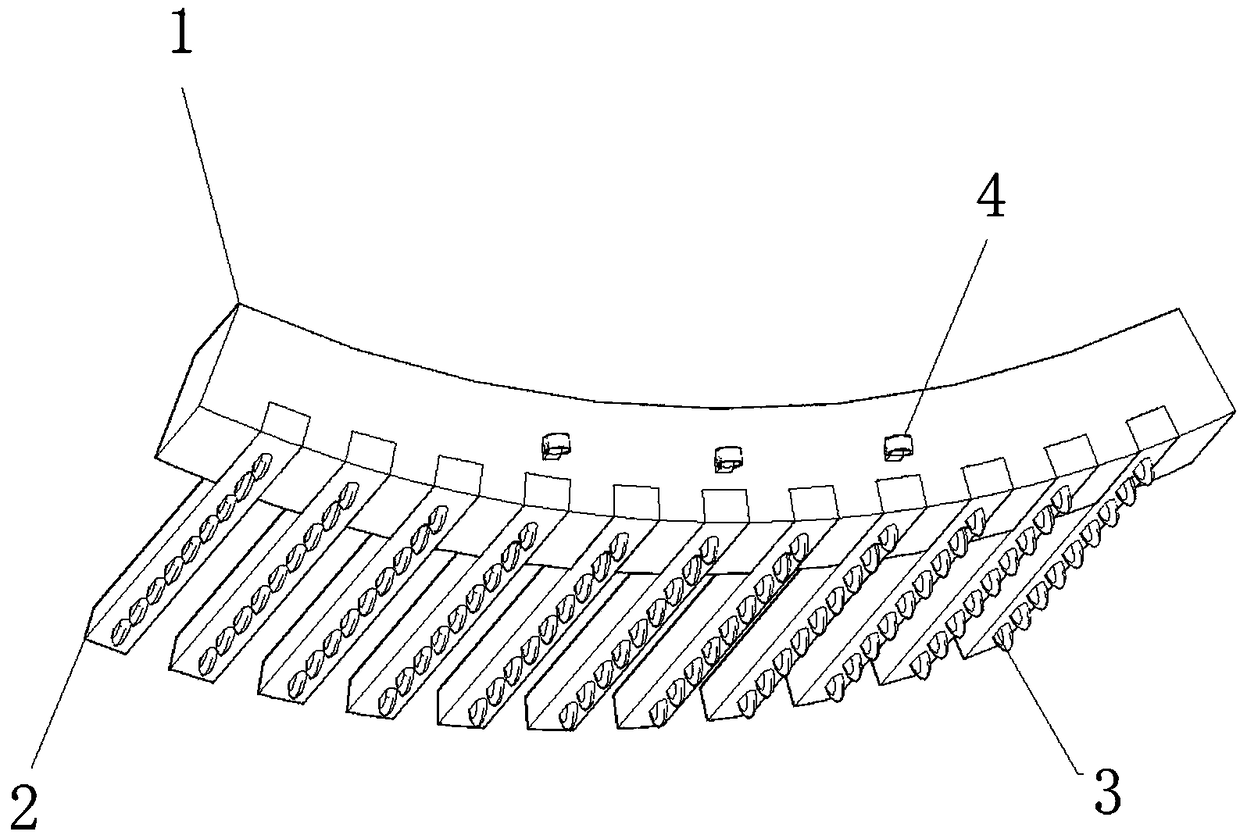

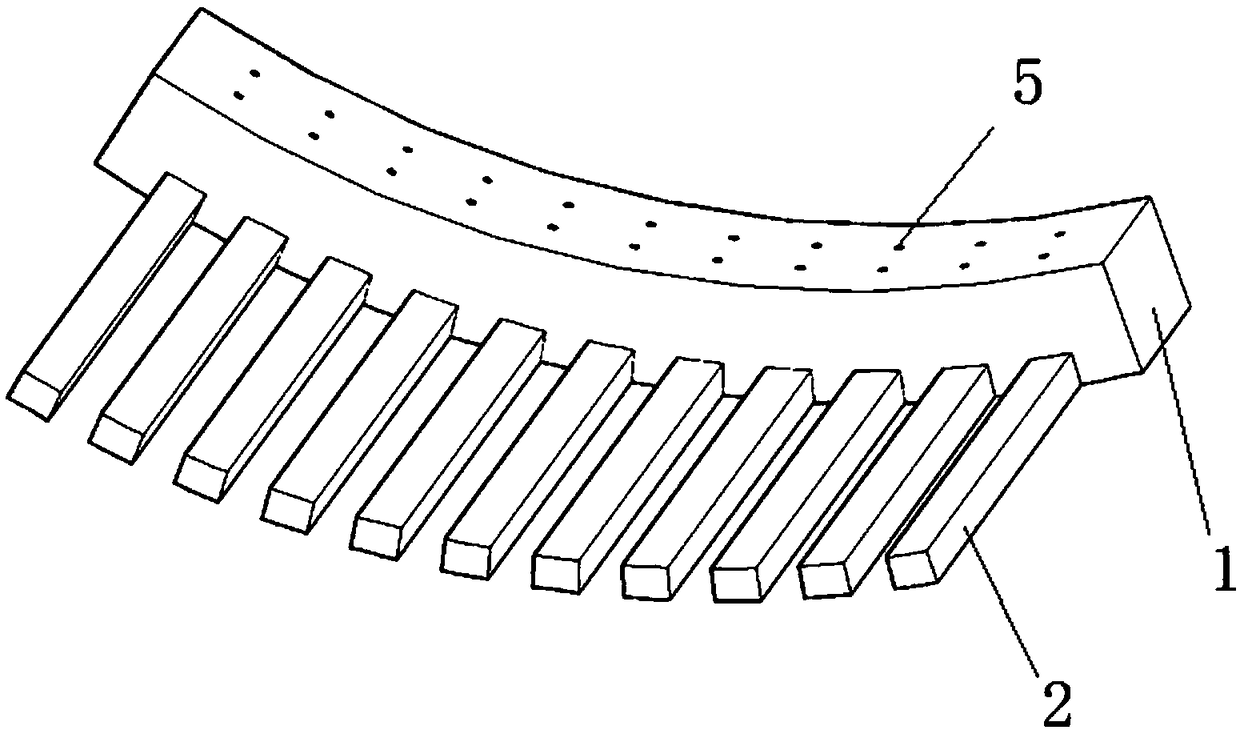

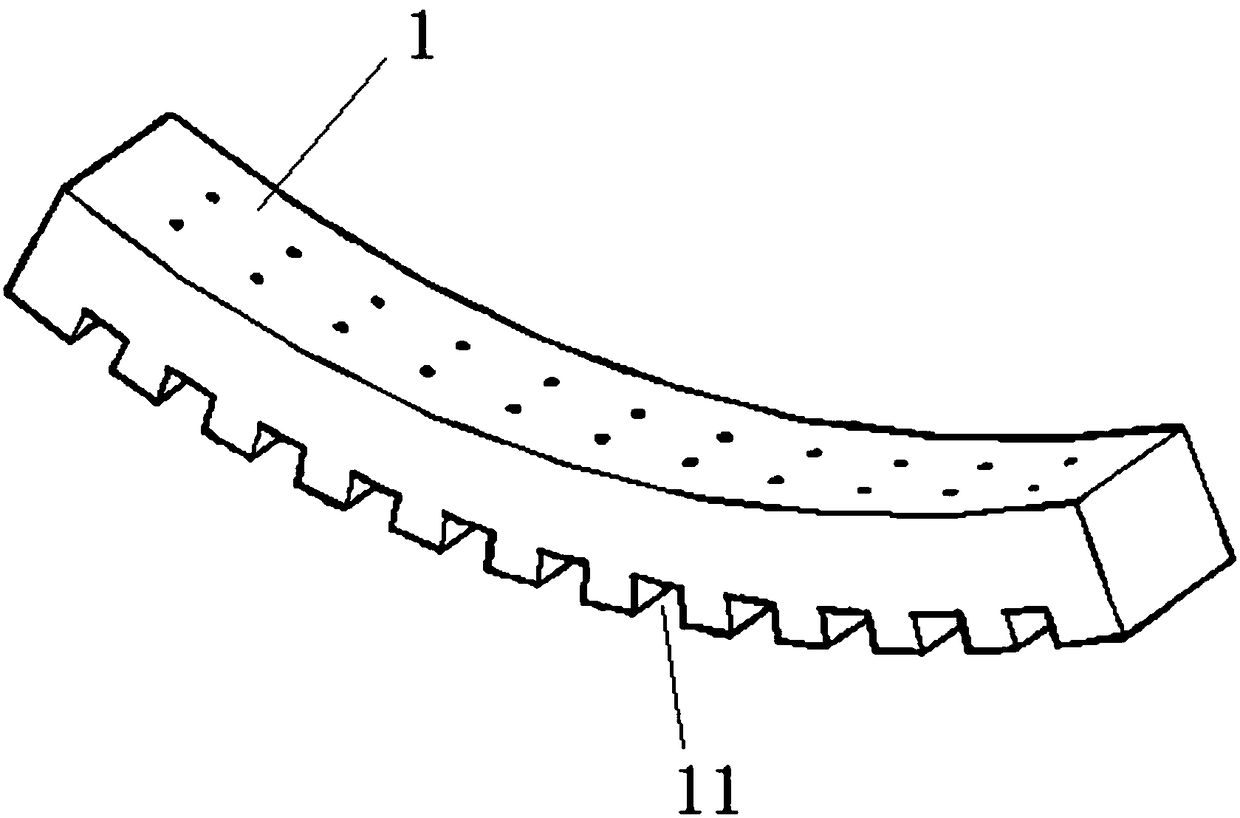

[0031] Such as figure 1 , 2 As shown, the temporary support device for TBM tunnel construction segment disclosed by the present invention includes a fixed base 1 and a support bar 2, the front end of the support bar 2 is fixedly connected to the fixed base 1, there are multiple support bars 2, and the support bars 2 are on the same Arranged in parallel and at intervals on the circumference; rollers 3 are installed on the bottom of the support bar 2 .

[0032] In order to ensure the tight fit between the steel support block and the segment 6, the top surface of the support bar 2 is an arc surface, and the diameter of the arc surface is equal to the outer diameter of the segment 6 to be applied. Preferably, the bottom surface of the support bar 2 is also an arc su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com