A kind of environment-friendly high-performance composite brake pad material and preparation method

A high-performance, environmentally friendly technology, applied in the field of brake pad materials, can solve the problems of unsatisfactory wear resistance, unfriendly environment and human body, poor high temperature resistance, etc., achieve low noise, inhibit thermal decomposition, and combine well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

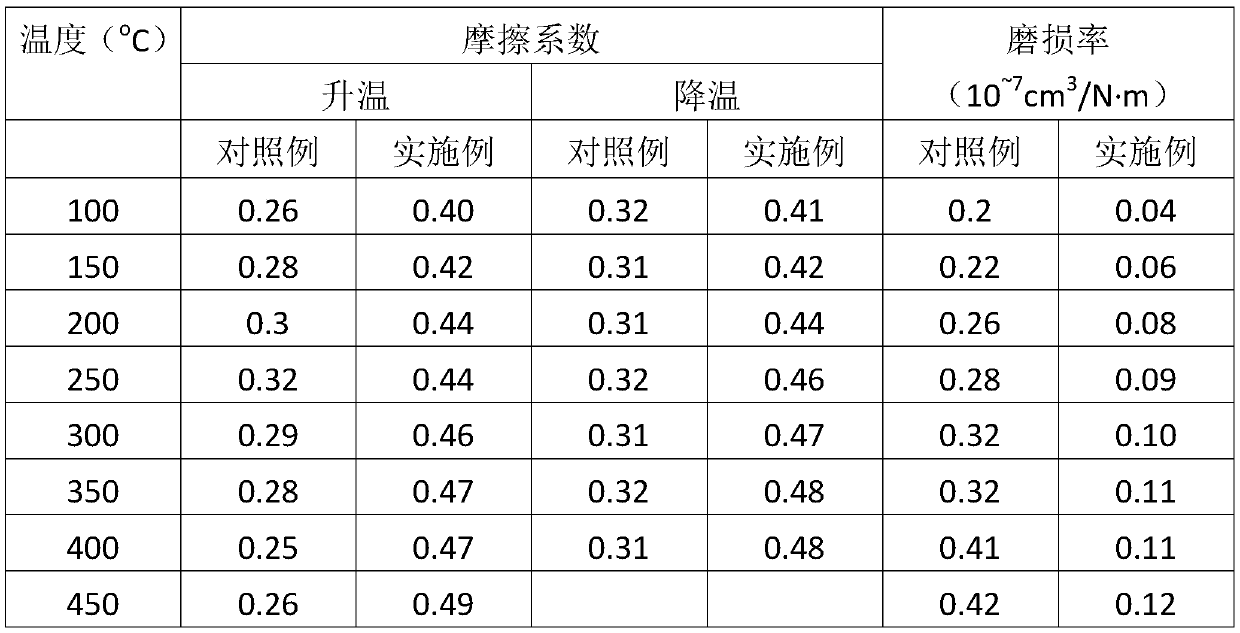

Embodiment 1

[0034] In parts by weight, the raw materials of the environment-friendly high-performance composite brake pad material in this embodiment include the following components: 8 parts of modified phenolic resin, 30 parts of reinforcing fiber, 11 parts of artificial graphite, 3 parts of petroleum coke, 3 parts of expanded Toughened graphite, 3.5 parts of zinc sulfide, 1 part of stannous sulfide, 0.5 parts of molybdenum disulfide, 26 parts of friction powder, 10 parts of barium sulfate, 4 parts of dolomite.

[0035] The reinforcing fiber is a mixture of potassium titanate fiber, calcium silicate fiber, aramid fiber and mineral fiber; the mass ratio of potassium titanate fiber, calcium silicate fiber, aramid fiber and mineral fiber is 10:10:3:7 ;

[0036] The friction powder is a mixture of brown corundum powder and NiTi alloy powder, and the mass ratio of NiTi alloy powder to brown corundum powder is 21:5;

[0037] In parts by weight, the amount of brown corundum powder added in th...

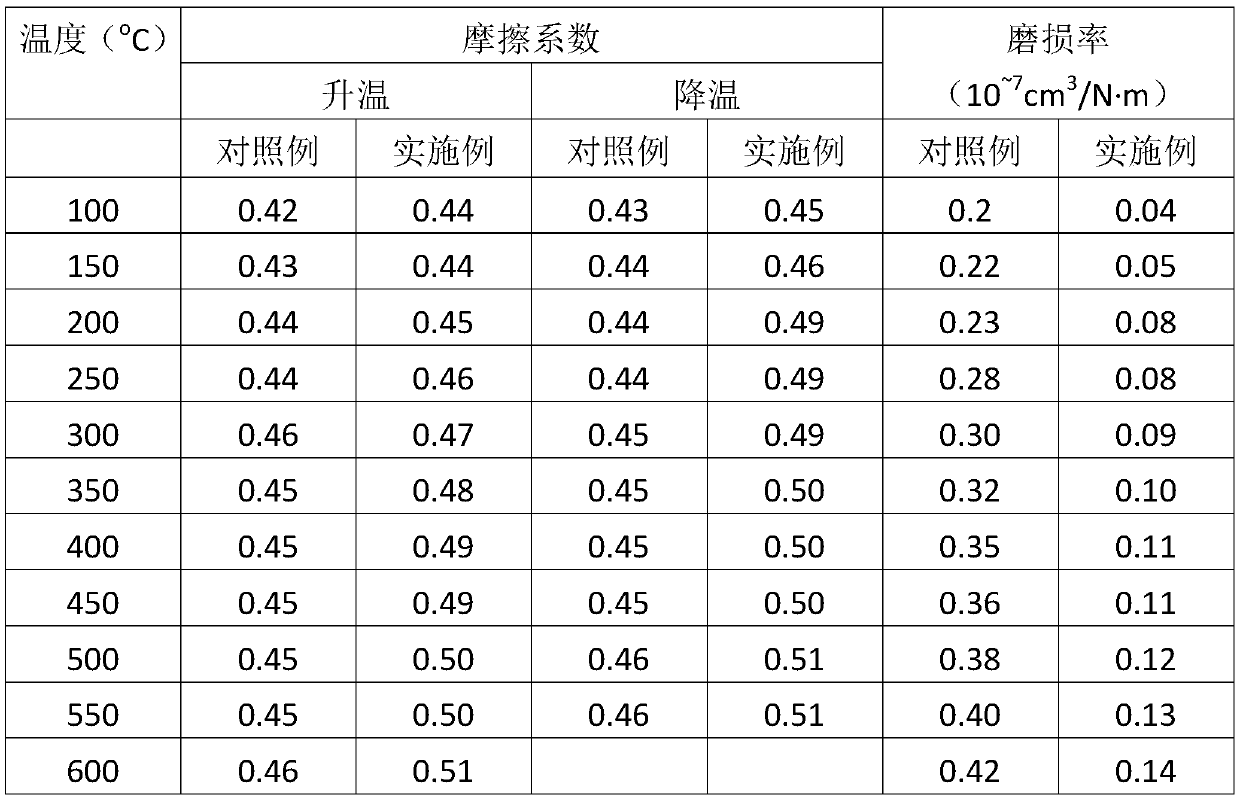

Embodiment 2

[0049] The environment-friendly high-performance composite brake pad material of this embodiment comprises the following components by weight: 9 parts of modified phenolic resin, 23 parts of reinforcing fiber, 8 parts of artificial graphite, 2 parts of petroleum coke, and 3 parts of expanded and toughened graphite , 5 parts of zinc sulfide, 2 parts of stannous sulfide, 1 part of molybdenum disulfide, 36 parts of friction powder, 8 parts of barium sulfate, and 3 parts of dolomite.

[0050] The reinforcing fiber is a mixture of potassium titanate fiber, calcium silicate fiber, aramid fiber and mineral fiber; the ratio is potassium titanate fiber: calcium silicate fiber: aramid fiber: mineral fiber=8:8:2: 5;

[0051] The friction powder is a mixture of brown corundum powder and NiTi alloy powder, and the ratio of NiTi alloy powder to brown corundum powder is 29:7;

[0052] The amount of brown corundum powder added in the brake pad material is 7 parts;

[0053] Further, the part...

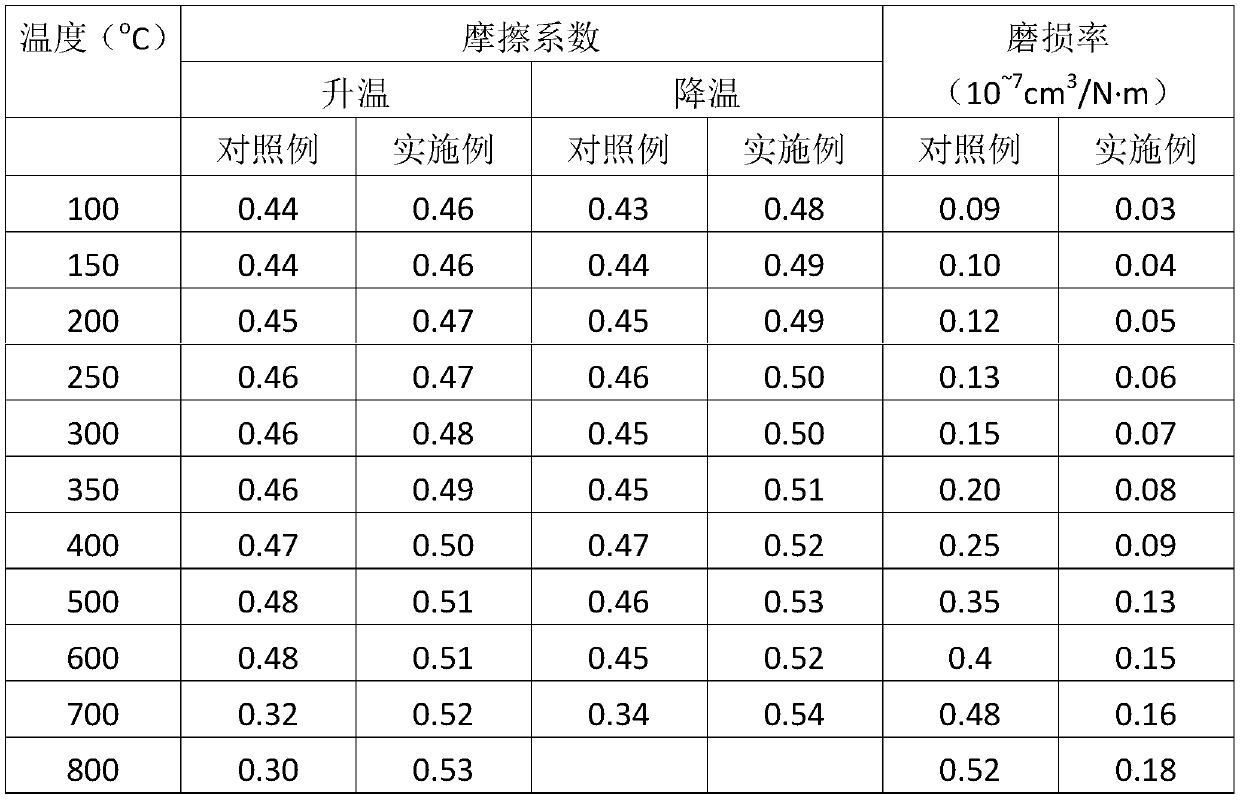

Embodiment 3

[0065] The environment-friendly high-performance composite brake pad material of this embodiment comprises the following components by weight: 8 parts of modified phenolic resin, 19 parts of reinforcing fiber, 7 parts of artificial graphite, 1 part of petroleum coke, and 3 parts of expanded and toughened graphite , 8 parts of zinc sulfide, 3 parts of stannous sulfide, 3 parts of molybdenum disulfide, 41 parts of friction powder, 5 parts of barium sulfate, and 2 parts of dolomite.

[0066] The reinforcing fiber is a mixture of potassium titanate fiber, calcium silicate fiber, aramid fiber and mineral fiber; the ratio is potassium titanate fiber: calcium silicate fiber: aramid fiber: mineral fiber=7:6:3: 3;

[0067] The friction powder is a mixture of brown corundum powder and NiTi alloy powder, and the ratio of NiTi alloy powder to brown corundum powder is 35:6;

[0068] The amount of brown corundum powder added in the brake pad material is 6 parts;

[0069] Further, the part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com