Barcode reading apparatus for rechargeable battery

A rechargeable battery, barcode reading technology, applied in electromagnetic radiation induction, instruments, induction record carriers, etc., can solve the problems of manual misoperation, traceability, and cumbersome traceability of single battery information, and achieve the effect of high degree of automation and easy traceability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

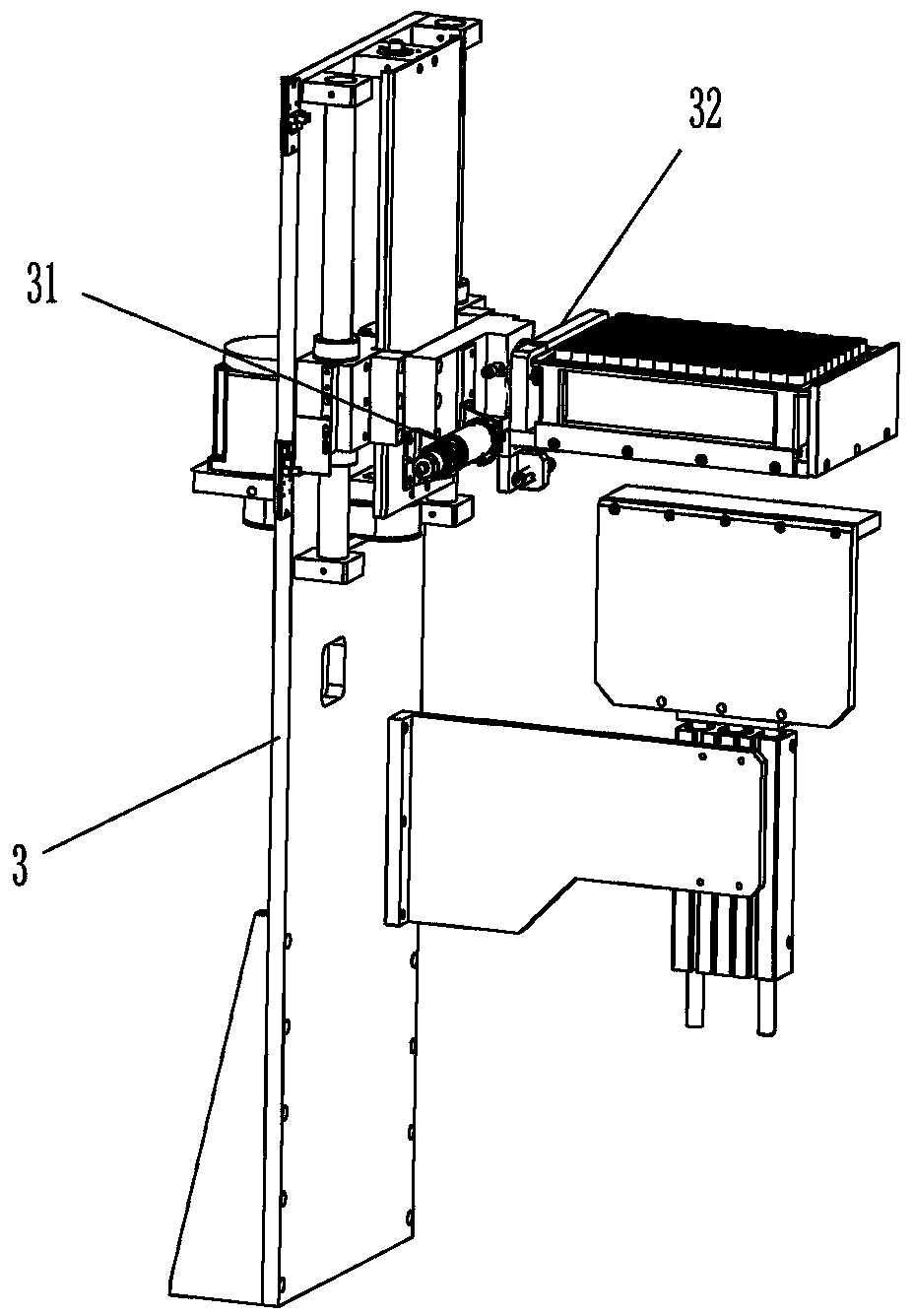

[0034] Such as figure 2 As shown, the present invention provides an embodiment of the automatic turning mechanism 3, the automatic turning mechanism 3 includes a second motor 31, a holder 32, a first bevel gear and a second bevel gear, the second bevel gear is connected to the holder 32 Bottom, holder 32 is used for placing the pallet 27 that rechargeable battery is housed, and second motor 31 is coaxially connected with the first bevel gear, and the first bevel gear is meshed with the second bevel gear, and the second motor 31 works to drive the first bevel gear. The bevel gear rotates, thereby driving the second bevel gear to rotate, and then the holder 32 is rotated.

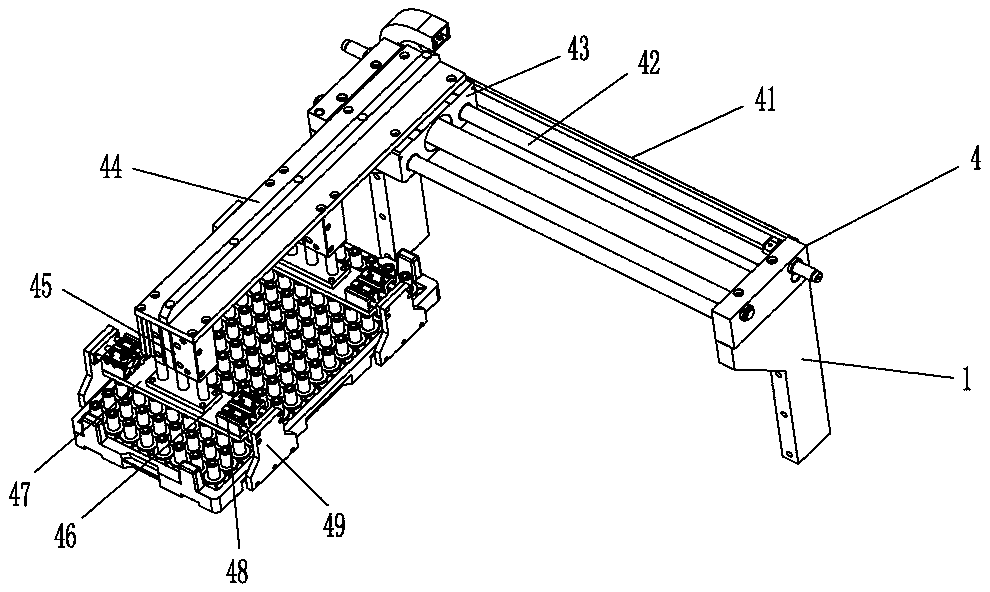

[0035] Such as image 3 As shown, the present invention provides an embodiment of the first grabbing mechanism 4, the first grabbing mechanism 4 includes a machine platform 41 connected to the frame 1, the machine platform 41 is provided with a slide bar 42, and on the slide bar 42 Sliding block 43 is slee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap