Control system of three-dimensional laser carving machine

A control system, three-dimensional laser technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., to achieve the effect of convenient operation, prevention of splash and injury, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

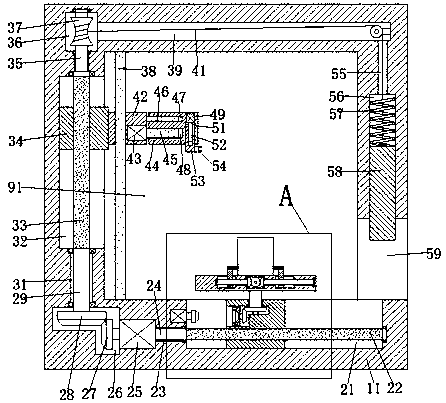

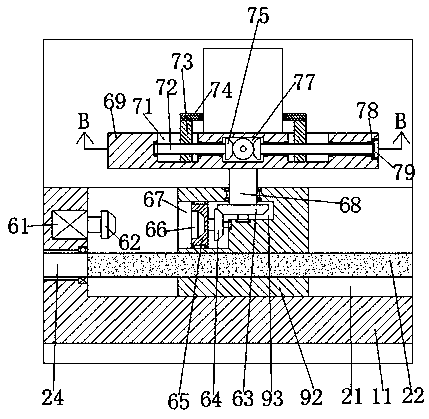

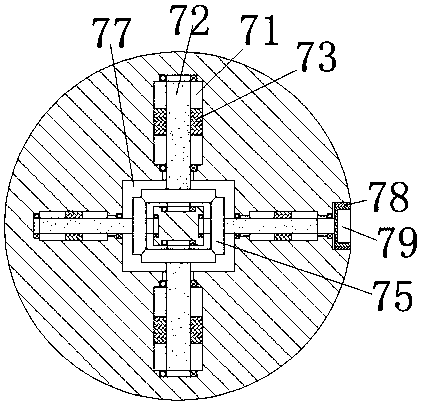

[0014] Such as Figure 1-Figure 3As shown, a control system of a three-dimensional laser engraving machine of the present invention includes a device main body 11 and an engraving device arranged in the device main body 11, and the engraving device includes a first cavity arranged in the device main body 11. A cavity 91, the first cavity 91 is provided with a first through hole 59 penetrating left and right in the right inner wall near the lower side, and a closing device is arranged in the upper inner wall of the first through hole 59, and the first through hole 59 is provided with a closing device. The lower inner wall of the cavity 91 is connected with a second cavity 21, and the right inner wall of the second cavity 21 is provided with a first motor 25, and the right end of the first motor 25 is connected to the first motor 25. A second through hole 23 is provided between the two cavities 21, and the right end of the first motor 25 is power-fitted with a first rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com