Hub type damping system

A shock absorbing system and hub-type technology, applied in the direction of wheels, highly elastic wheels, transportation and packaging, etc., can solve the problems of vehicle center of gravity deviation, eliminate weak vibration, and produce severe vibration, so as to ensure stability and reduce The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

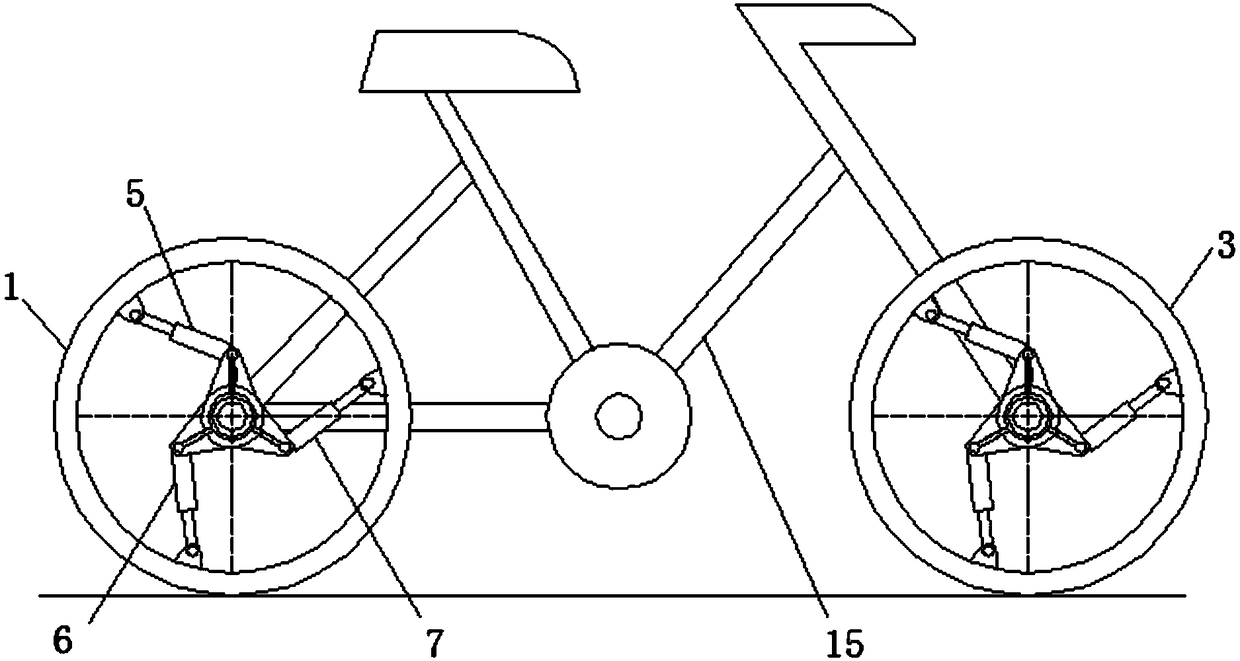

Image

Examples

no. 1 example

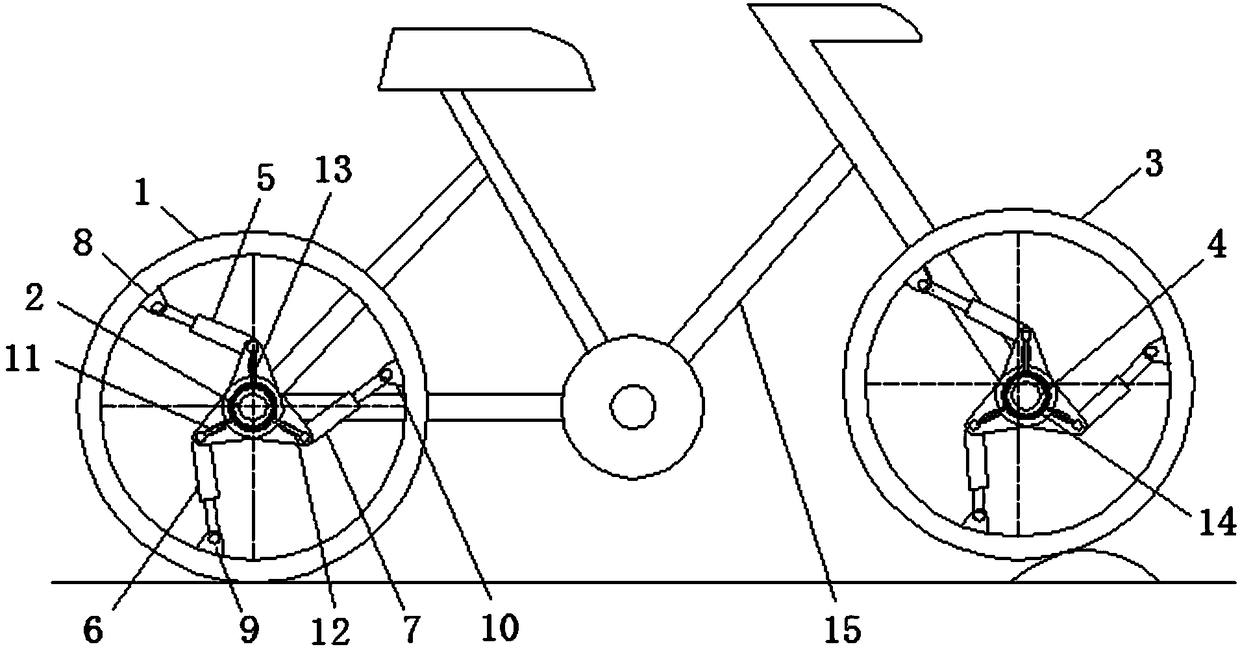

[0020] As a first embodiment of the present invention, the first gas spring 5 , the second gas spring 6 and the third gas spring 7 are installed on the linkage plate and can rotate around the hinge point.

[0021] The distribution valve 14 is installed on the first interlocking disk 2 and the second interlocking disk 4, and there are three groups of quick-plug joints on the distribution valve 14, respectively connecting the first air pipe 11, the second air pipe 12 and the third air pipe 13, the first air pipe 11, the second air pipe The second gas pipe 12 and the third gas pipe 13 communicate with the spring cylinders of the first gas spring 5 , the second gas spring 6 and the third gas spring respectively.

[0022] As a first embodiment of the present invention, the distributing valve 14 is in the form of a ring, and is installed on the disk surfaces of the first linkage disk 2 and the second linkage disk 4 through flanges.

[0023] As the first embodiment of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com