Steel plate storage device and method for finished stock storeroom of medium and thick plate rolling mill

The technology of storage device and finished product warehouse is applied in the field of storage device of steel plate in finished product warehouse of medium and heavy plate rolling mill, which can solve the problem of spending a lot of manpower and material resources, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail now in conjunction with accompanying drawing.

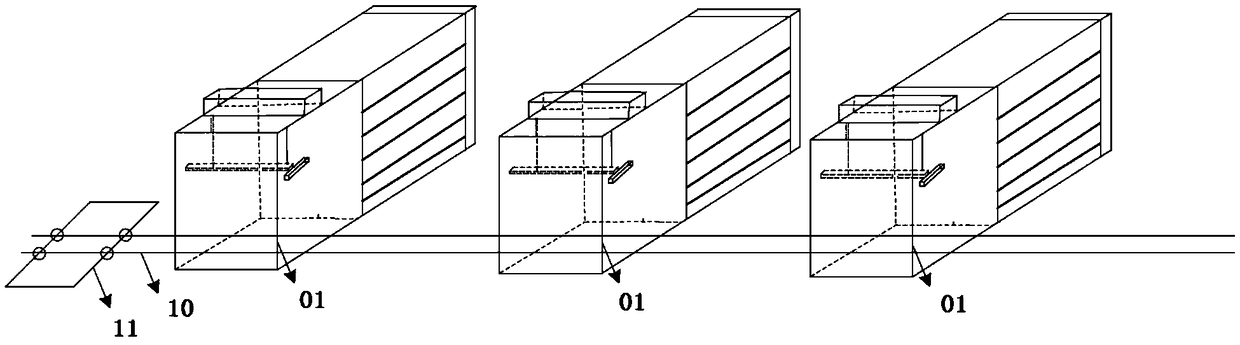

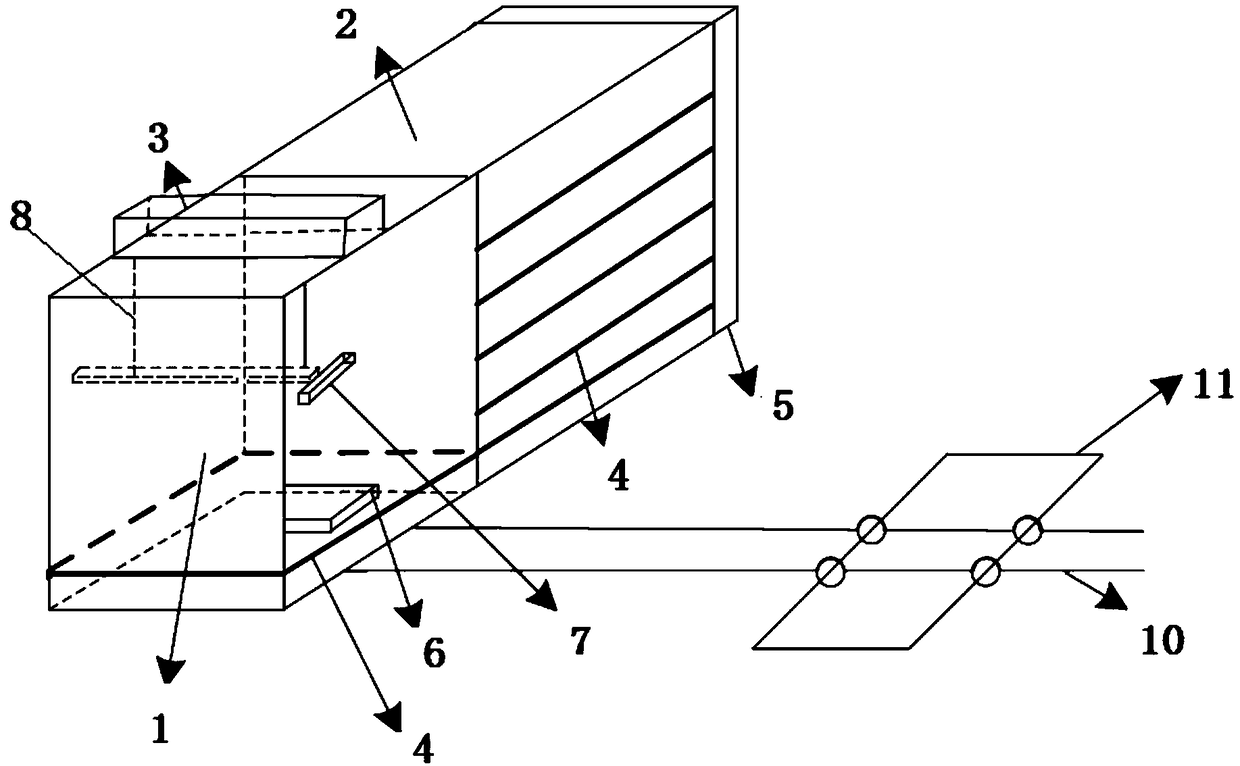

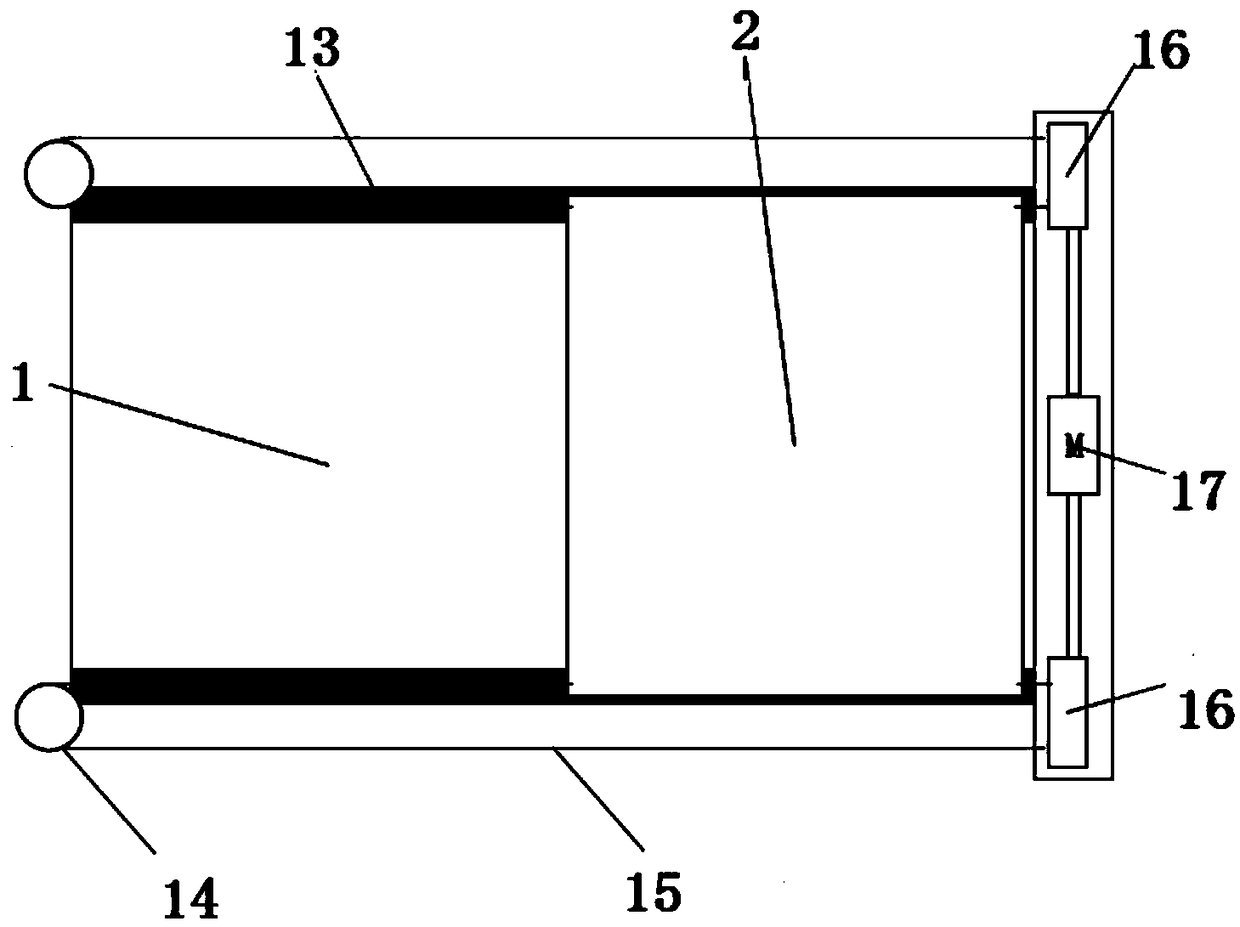

[0025] according to Figure 1 to Figure 3 The storage device for the steel plate in the finished product warehouse of the medium and heavy plate rolling mill is shown. The concept of modularization of the finished product warehouse is introduced. Each module is a steel plate storage device, including multiple storage racks 01, transport trolleys 11, rails 10, and lifting devices. And electromagnetic chuck electric control device 3, traverse device, and supporting electrical system, the storage platform 01 is made of high-strength steel with strong bearing capacity, and storage area 2 and hoisting area 1 are arranged side by side in the storage platform 01 , the storage area 2 is responsible for storing the steel plate, the storage area 2 is horizontally provided with a plurality of storage positions 4, preferably 5 storage positions 4, and the storage positions 2 are mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com