Inflatable airtight isolation valve

An isolation valve, inflatable technology, applied in the direction of inflatable valves, valve details, valve devices, etc., can solve the problems of circular airtight isolation valve valve weight, reduced facility sealing, large ventilation, etc., to achieve mechanical The effect of low strength requirement, simple structure and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

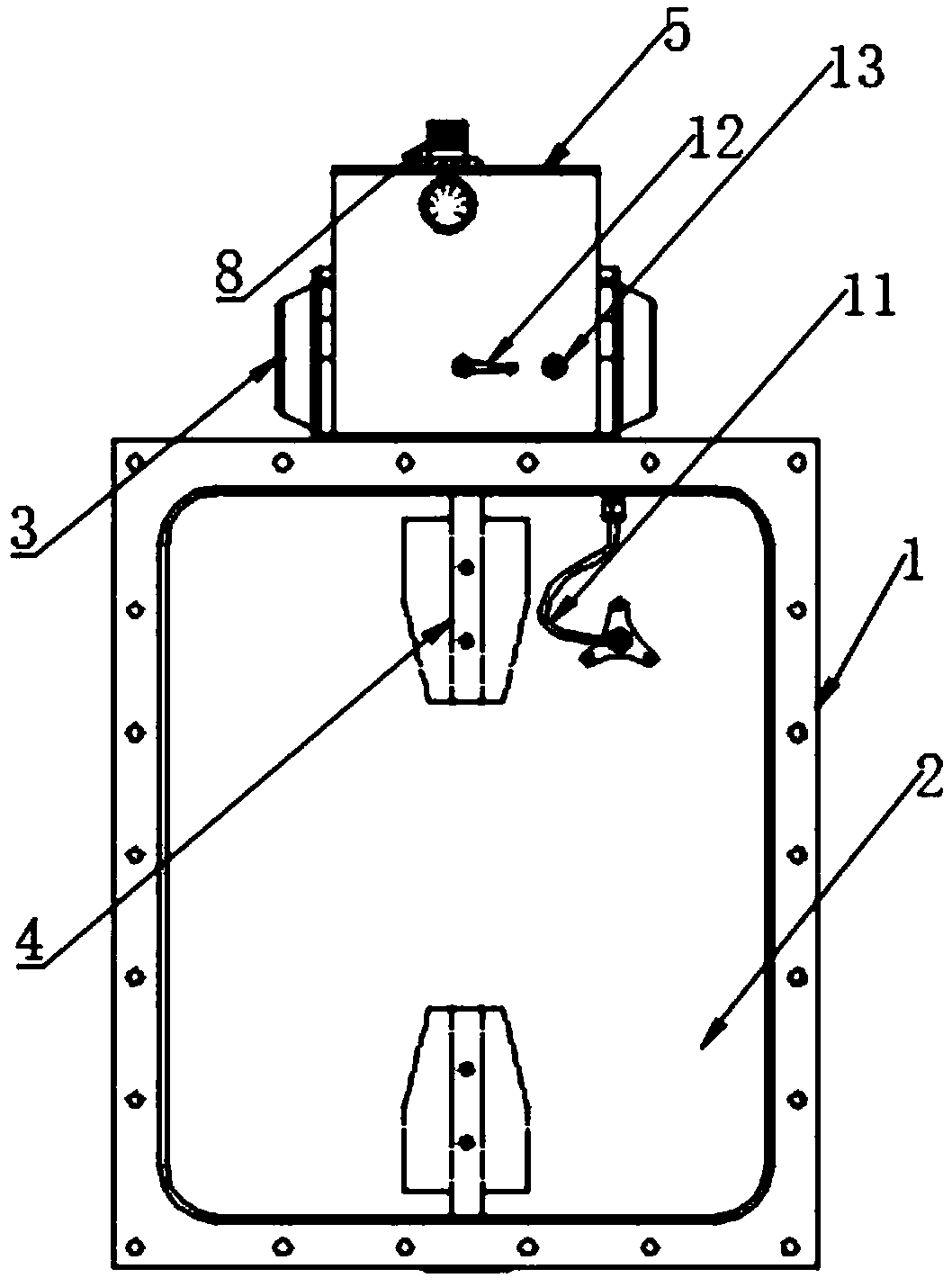

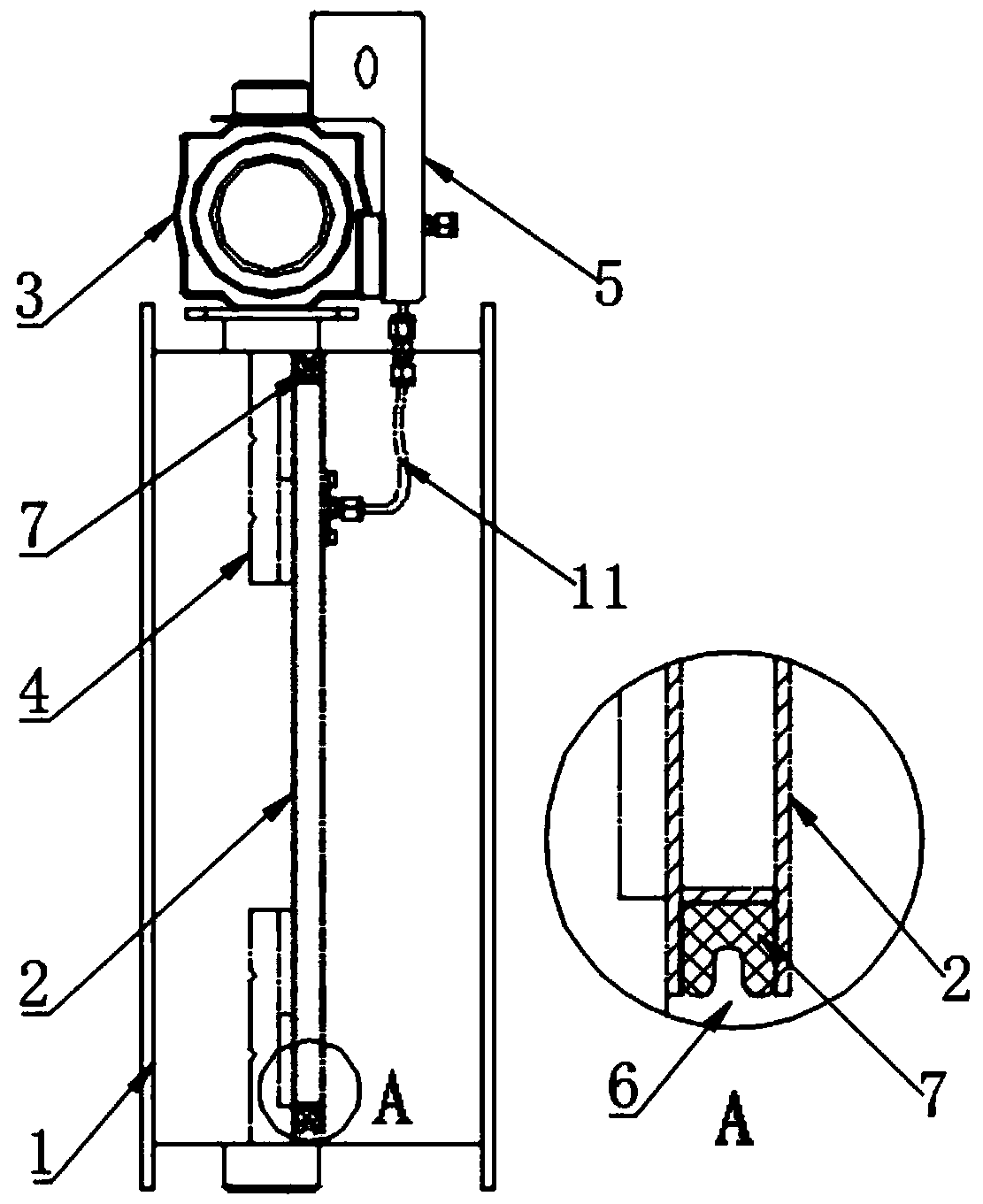

[0030] First refer to Figure 1~3 The inflatable airtight isolation valve of the present invention will be described. Such as figure 1 and 2 As shown, the inflatable airtight isolation valve of the present invention includes a valve body 1, a valve plate 2, a switch actuator 3, a rotating shaft 4, an inflatable air bag 7 and an inflation system; The rotating shaft 4, the rotating shaft 4 passes through the valve body 1 and is connected with the switch actuator 3 arranged outside the valve body 1, the valve plate 2 is located in the valve body 1 and is connected with the rotating shaft 4, the switch actuator 3 controls the rotation of the rotating shaft 4 to control Rotation of the valve plate 2; the inflatable air bag 7 surrounds the periphery of the valve plate 2, the inflation system communicates with the inflatable air bag 7, and is used to inflate the inflatable air bag 7, the groove 6 is set on the periphery of the valve plate 2, and the inflatable air bag 7 is arranged...

Embodiment 2

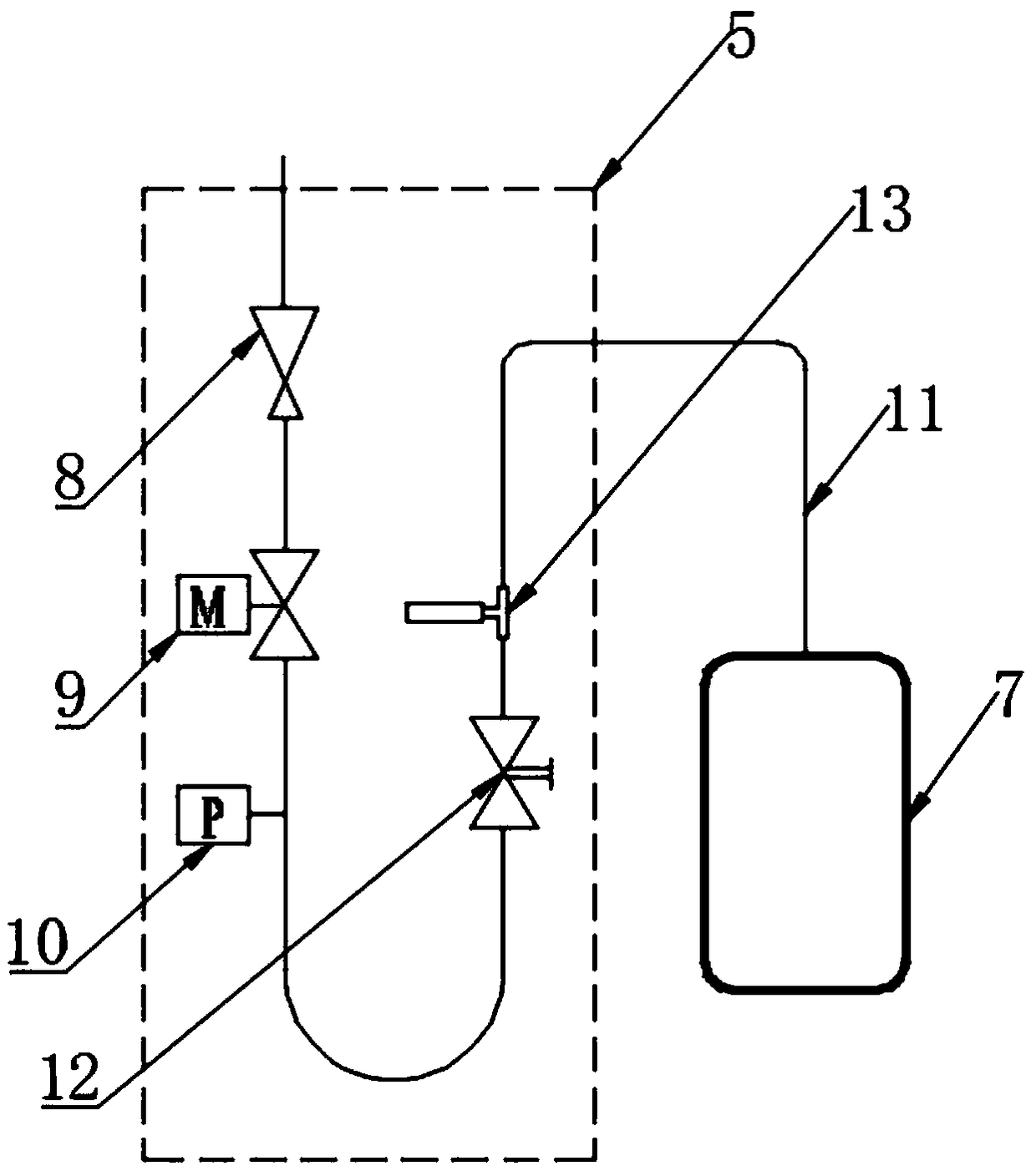

[0034] In another embodiment of the present invention, the inflatable air-tight isolation valve includes, in addition to the device in the first embodiment above, an air-tightness detection device, including a manual shut-off valve 12 and an air-tightness detection interface 13; the manual shut-off valve 12 and The differential pressure switch 10 is connected, and the air tightness detection interface 13 is arranged on the inflation pipeline 11 between the manual shut-off valve 12 and the inflation airbag 7, and is used to detect the The airtightness of the inflated airbag 7 is used to determine the tightness of the isolation valve. In addition, the manual stop valve 12 and the air tightness detection interface 13 can also be fixed on the control panel 5 as required.

Embodiment 3

[0036] The present invention also provides a method for detecting air tightness. The method adopts the inflatable air-tight isolation valve of Embodiment 2. After the switch actuator 3 controls the rotating shaft 4 to rotate the valve plate 2 to the set sealing position, it is opened. Solenoid valve 9, the gas inflates the inflatable airbag 7 through the inflation pipeline 11, and the inflatable airbag 7 expands out of the groove 6. After the inflation is completed, the inflatable airbag 7 closes the gap between the valve body 1 and the valve plate 2 to achieve a sealed state , the inflatable airtight isolation valve is normally closed;

[0037] After the inflatable airtight isolation valve reaches the normal closed state, the external pressure detection device is airtightly connected to the airtight detection interface 13. After the pressure is stable, close the manual shut-off valve 12, and observe the change value of the gas pressure of the inflatable airbag 7 per unit time....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com