Food cooking equipment

A cooking equipment, food technology, applied in the direction of household utensils, roasters/barbecue grids, utensils for frying things in oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

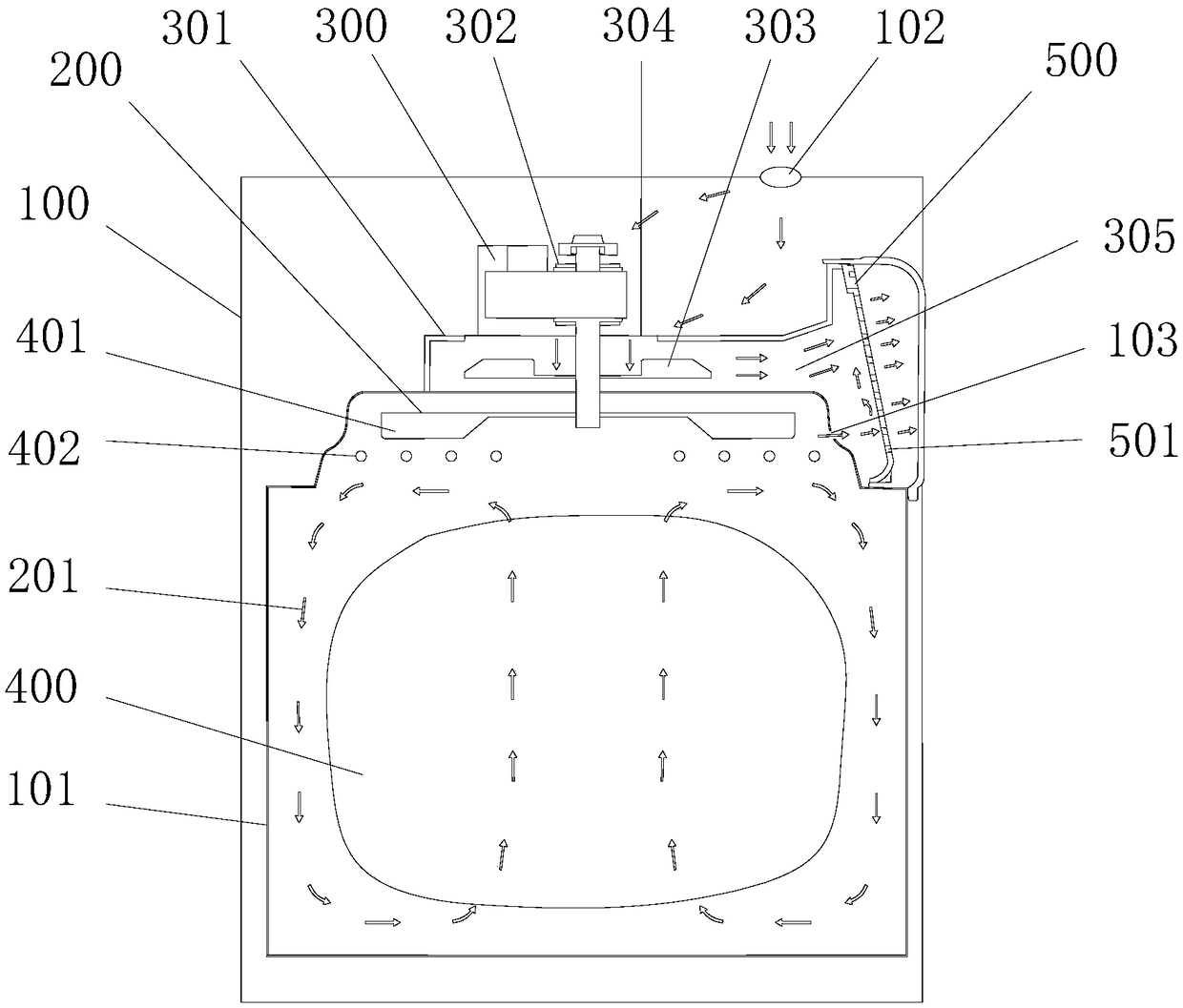

[0053] This embodiment provides a food cooking device, specifically a device for heating food by blowing high-temperature gas to the food, such as figure 1 As shown, it shows the working process of the air distribution device in the food cooking equipment, wherein the food cooking equipment includes: a casing 100, a hot air flow generating device 200 and a cold air flow device 300, specifically, the lower part of the inside of the casing The food cooking chamber 101 is provided at the position of the food cooking chamber 101, and the food cooking chamber 101 is used to heat the food 400 to be cooked. Preferably, the food 400 is placed in a drawer-type frying basket (or a rotating cage) for example, so as to evenly heat the food 400 .

[0054]The hot air flow generating device 200 is arranged on the top of the food cooking chamber 101, and it is used to generate a flowing hot air flow 201, and the generated hot air flow 201 can circulate in the food cooking chamber 101, constan...

Embodiment 2

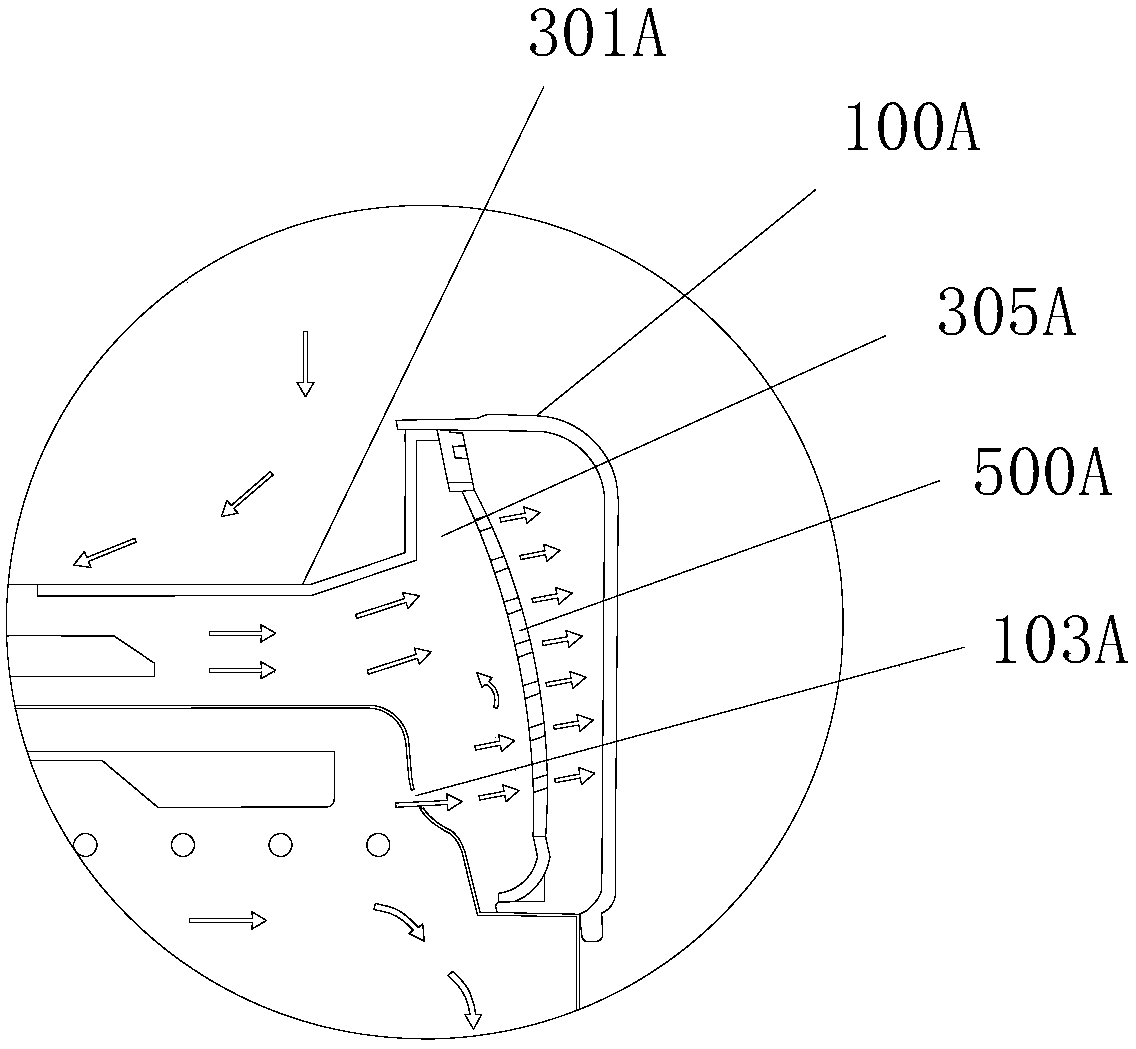

[0059] The difference between this embodiment and Embodiment 1 is that another air distribution device 500A is provided, such as figure 2 As shown, it specifically shows the working process of the high-temperature gas discharged from the water vapor outlet passing through the air distribution device 500A, wherein the air distribution device 500A completely covers the air discharge channel 305A, and the air distribution device 500A is along the direction of the gas in the air discharge channel. Flowing to the concave arc-shaped structure, the high-temperature gas discharged from the water vapor outlet 103A flows to the air distribution device 500A, a part of the high-temperature gas directly passes through the air distribution device 500A, and flows out to the outside of the housing 100A, and the other part of the high-temperature gas is in the air. Under the action of the flow distribution device 500A, the direction is changed to flow upwards, and it merges with the cold air f...

Embodiment 3

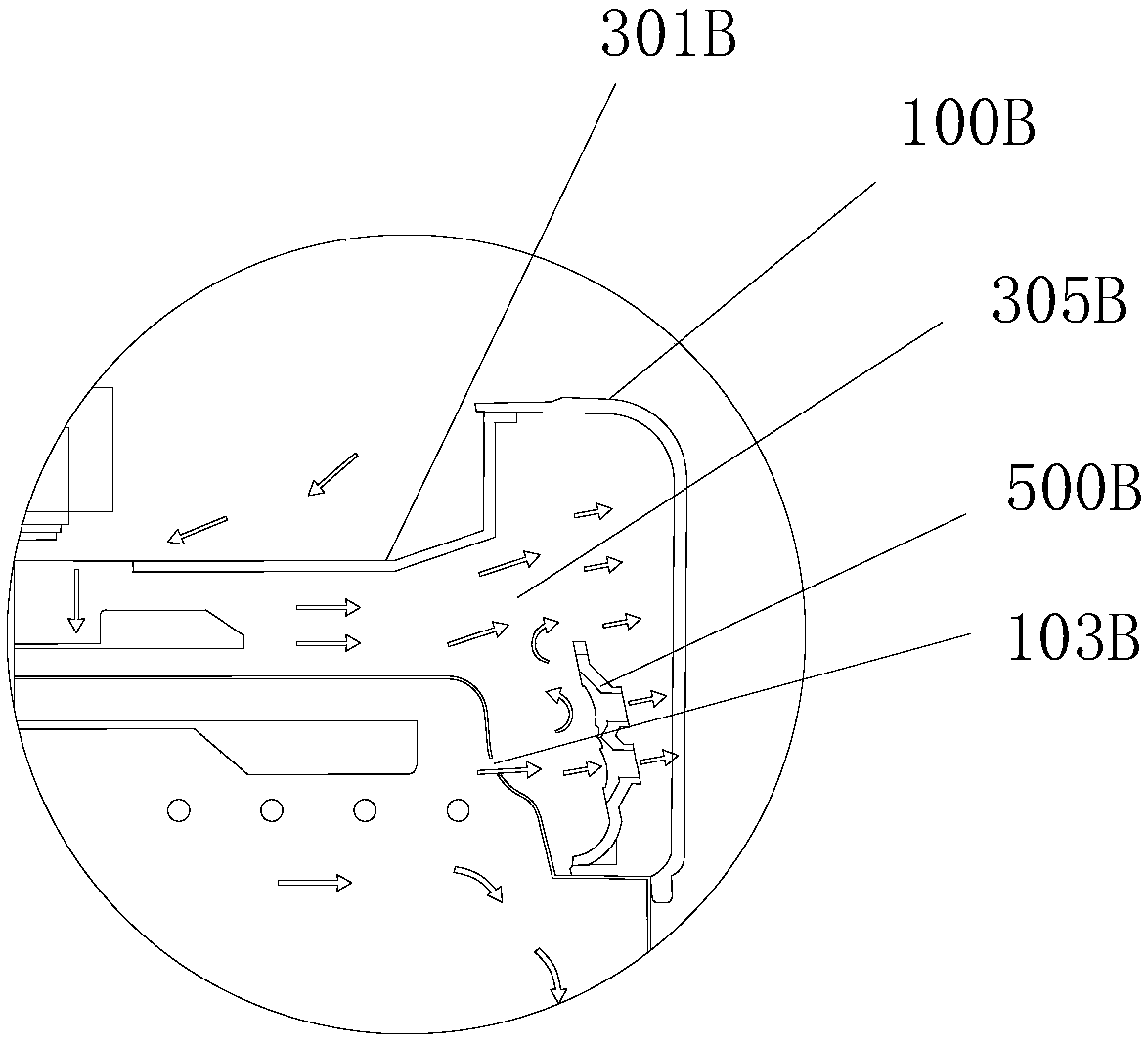

[0061] The difference between this embodiment and Embodiment 1 is that another air distribution device 500B is provided, such as image 3 As shown, it specifically shows the working process of the high-temperature gas discharged from the water vapor outlet passing through the air distribution device 500B, wherein the air distribution device 500B only partially covers the air discharge channel 305B, specifically, the air distribution device 500B completely covers the water vapor outlet 103B, and after the high-temperature gas discharged from the water vapor outlet 103B flows to the air distribution device 500B, almost all of the high-temperature gas changes direction and flows upward, and merges with the cold air flow discharged from the inside of the draft hood 301B to exchange heat After that, it passes through the air distribution device 500B and is discharged to the outside of the housing 100B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com