Shoe sole cleaning machine with spray disinfection function for high-heeled shoes

A technology for cleaning soles and high-heeled shoes, which is applied in disinfection, cleaning of boots and shoes, household cleaning devices, etc. It can solve the problems of unsuitable cleaning of high-heeled shoe soles, affecting cleaning efficiency and effect, and incompleteness. The effect of abnormal burning and eliminating the hidden danger of ankle sprain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

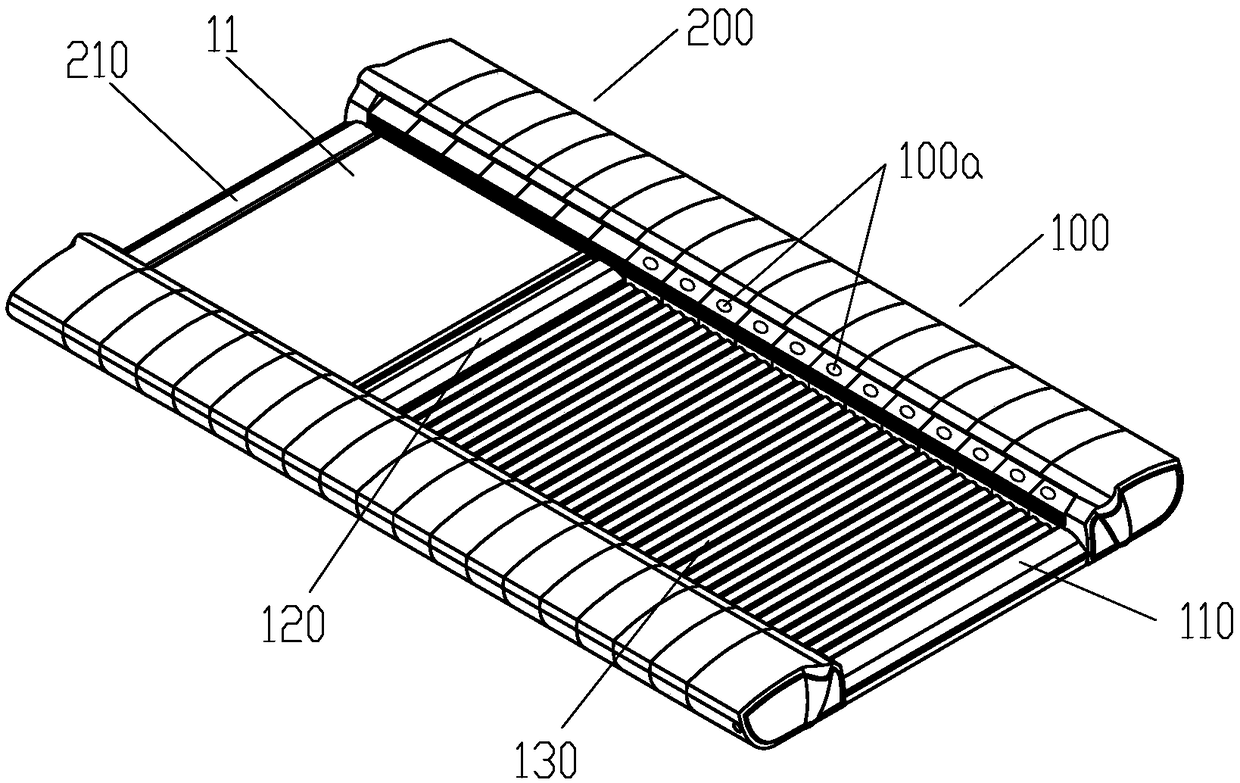

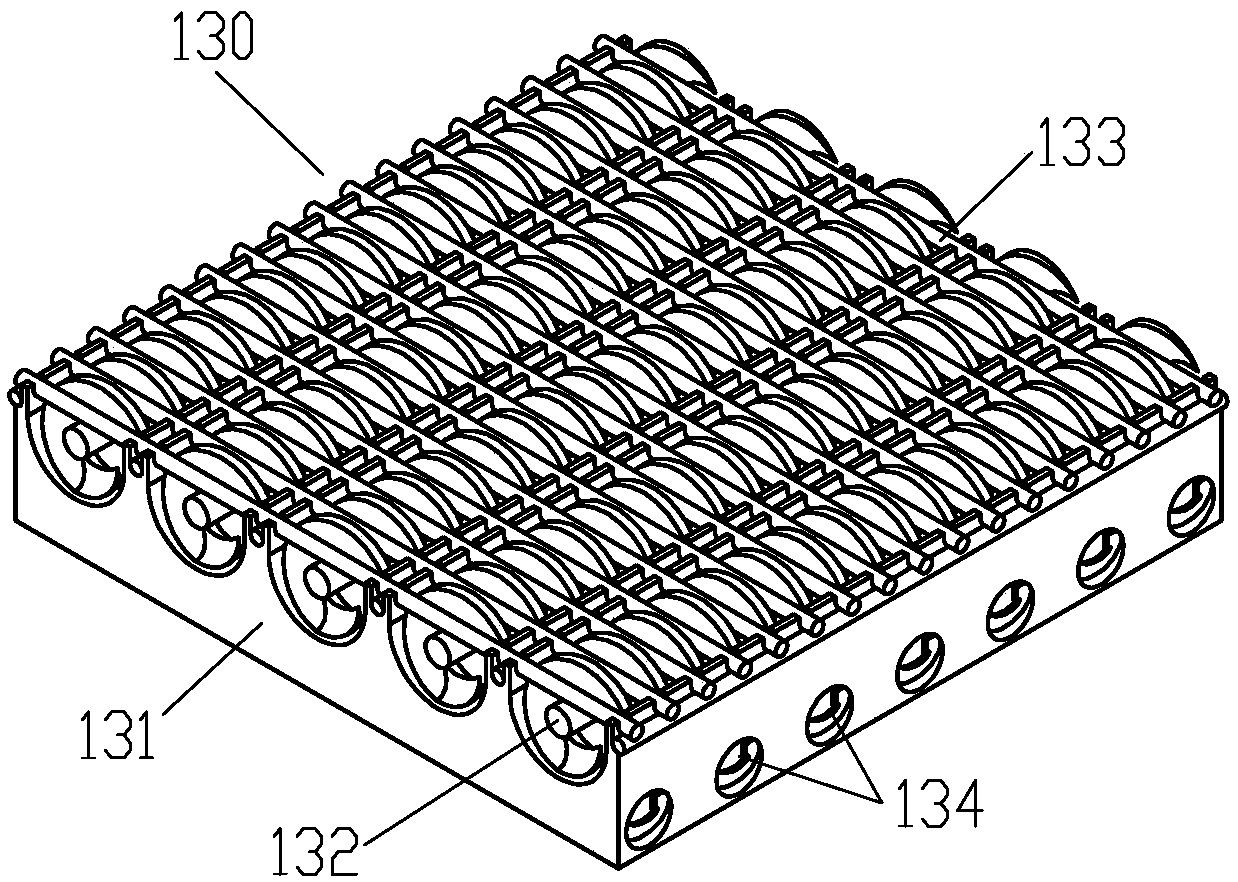

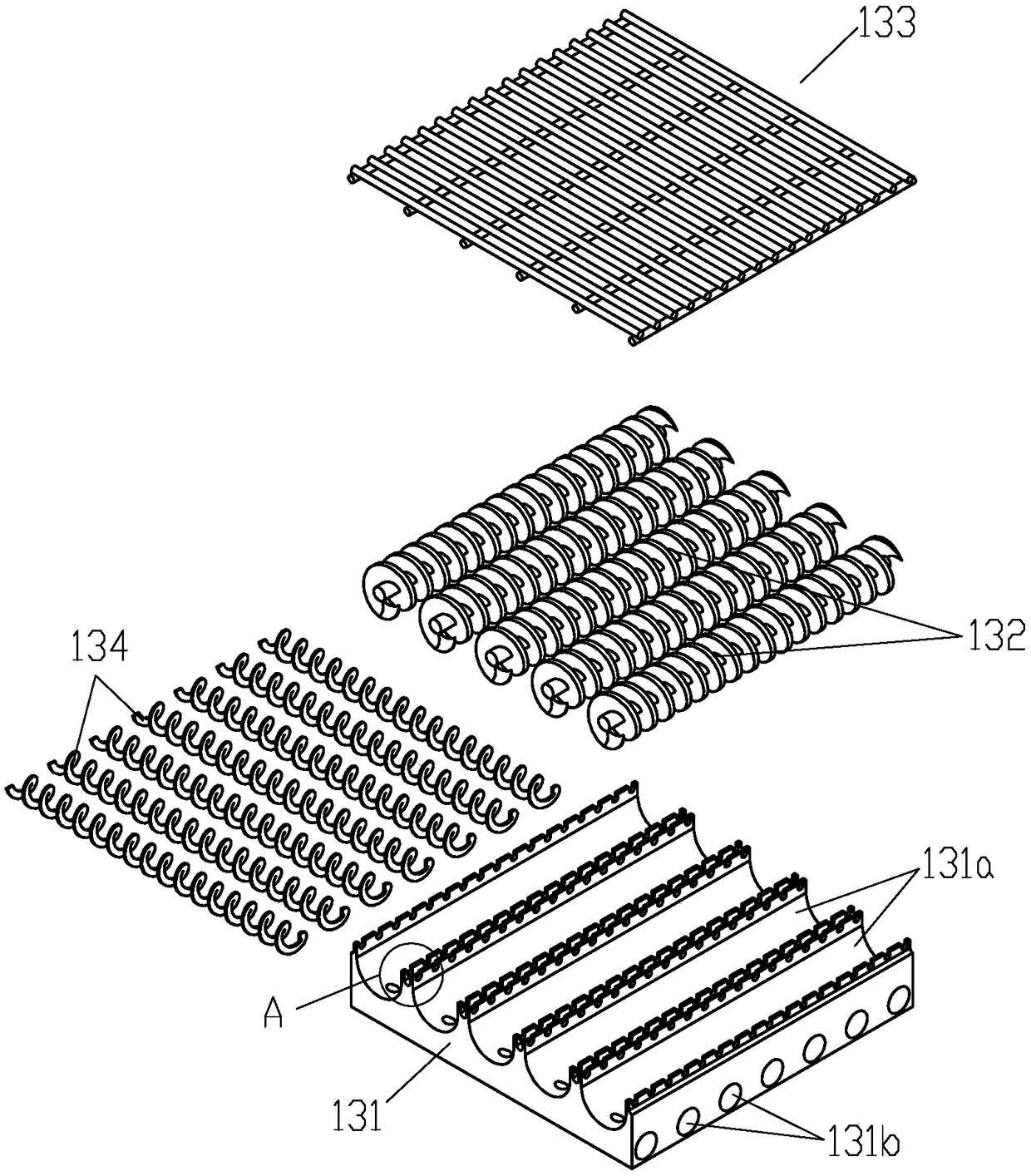

[0028] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7, a cleaning machine for high-heeled shoes with spray disinfection, comprising a cleaning unit 100, the outlet end of the cleaning unit 100 is assembled and connected with a sole drying unit 200; the cleaning unit 100 includes a cleaning unit skeleton, and the cleaning unit skeleton is opened upward Rectangular groove shape, cleaning member 130 is arranged in the rectangular groove of cleaning unit skeleton; The cleaning brush roller 132 of cleaning brush roller 132, the cleaning driving motor that is used to drive cleaning brush roller 132 is arranged in the side wall of cleaning unit skeleton side, and the output shaft of cleaning driving motor is coaxially connected with driving shaft, and the driving shaft is connected in series with A plurality of driving bevel gears, the driving bevel gear meshes with a driven bevel gear, the driven bevel gear is fixedly connected to...

Embodiment 2

[0032] Example 2, see Figure 10 , The twisted shaft 2 forms a one-way rotation structure through an overrunning clutch structure. The overrunning clutch structure includes a mandrel composed of a twisted shaft 2, on which an outer ring 6 is sleeved, and the outer ring 6 is rotatably arranged on the corresponding frame segment, and the corresponding frame segment is provided with a The locking screw 8 of the outer ring 6; the outer ring 6 is provided with a rolling body 9 through the receiving groove, and the rolling body 9 is in contact with the first spring 7, the first spring 7 is installed on the outer ring 6, and the first spring 7 is Push the rolling body 9 to one end of the receiving groove so that when the mandrel rotates in the set direction, the mandrel maintains the position of the rolling body 9 through friction, and the mandrel forms a combined state with the outer ring 6 through the rolling body 9; When the mandrel rotates in the opposite direction to the set di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com