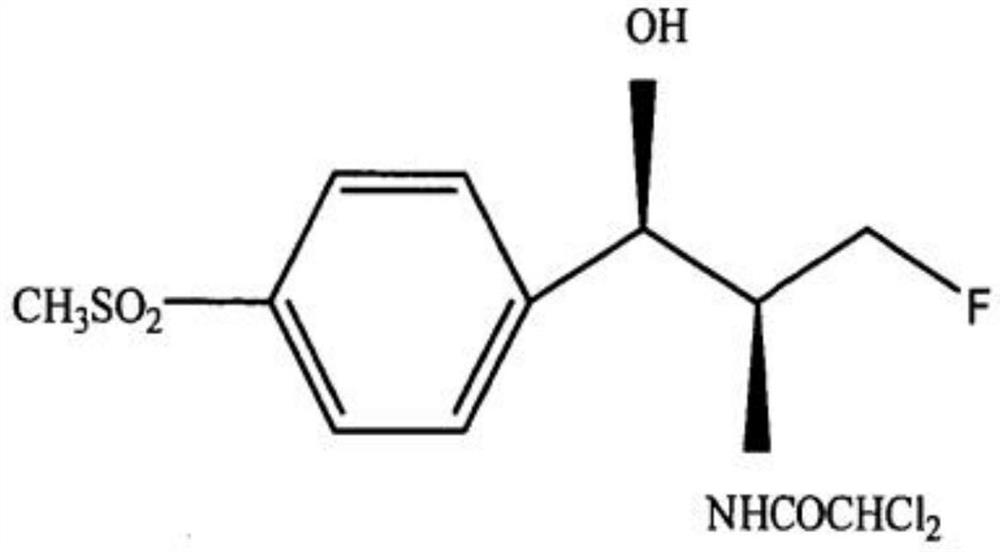

A kind of preparation method of florfenicol injection

A technology of florfenicol and injection, which is applied in the field of preparation of florfenicol injection, can solve the problems of recurrent infection, complicated process, large dosage, etc., and achieves reducing the pressure of filtration, prolonging the use period, and preparing the process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

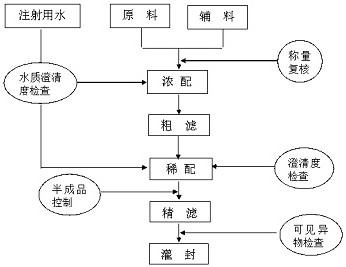

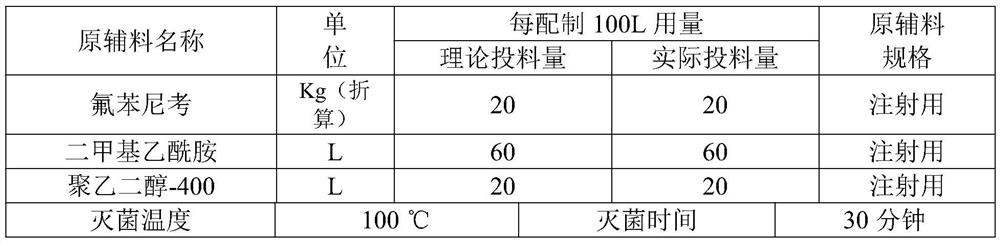

[0040] The preparation process of Florfenicol Injection:

[0041] Concentrated liquid:

[0042] 1) Wash the containers and utensils used for liquid preparation twice with water for injection.

[0043] 2) The water for injection used for dosing must be kept fresh (not exceeding 8 hours).

[0044] 3) Add florfenicol, dimethylacetamide, and polyethylene glycol-400 according to the prescription and stir to fully dissolve and mix well. Add water to 100L, stir for another 15 minutes, mix well, and filter.

[0045] 3) The concentrated medicinal liquid passes through a titanium rod filter and is filtered to a dilute tank.

[0046] Dilute solution:

[0047] 1) Notify the QA personnel to take samples and test the content. After passing the test, nitrogen protection is introduced into the liquid mixing tank.

[0048] filter:

[0049] 1) Before filtering, a complete inspection of the sterilizing filter should be carried out, and it should be cleaned after passing the test.

[0050]...

Embodiment 2

[0060] A preparation method of Florfenicol, the specific preparation steps are as follows:

[0061] Add 300L of methanol to the 2000L reaction kettle, start stirring, add the crude product of Florfenicol, heat to 80°C, and wait until the solid dissolves completely to form a methanol mixture with a concentration of 50mg / ml of Florfenicol, and pump the mixture to In the refining tank, start stirring and add 900L water dropwise, start stirring and cool down to 25°C at a rate of 6°C / h, keep stirring at 25°C for 30 minutes, then cool down to the initial 5°C at a rate of 6°C / h, keep stirring at 5°C for 40 minutes Afterwards, centrifuge. The solid obtained by centrifugation was rinsed with 180Kg of water. The wet product is vacuum-dried at 60°C for 6 hours, and the vacuum degree is ≥0.08MPa. The refined yield of the final product is 93.1%, the solvent residual methanol is 120ppm, and the Dv(90) is controlled to be 56 μm. The solubility of the florfenicol crystals prepared by the m...

Embodiment 3

[0063] A preparation method of Florfenicol, the specific preparation steps are as follows:

[0064] Add 300L of acetamide to the 2000L reaction kettle, start stirring, add the crude product of Florfenicol, heat to 80°C, wait until the solid is completely dissolved and configure the concentration of the methanol mixture of Florfenicol to be 80mg / ml, pump the mixture To the refining tank, start stirring and add 1200L water dropwise, start stirring and cool down to 28°C at a rate of 10°C / h, keep stirring at 28°C for 40min, then cool down to the initial 7°C at a rate of 10°C / h, keep stirring at 7°C After 60 min, centrifuge. The solid obtained by centrifugation was rinsed with 200Kg of water. The wet product is vacuum-dried at 70°C for 6-10h, and the vacuum degree is ≥0.08MPa. The refined yield of the final product is 94.8%, the solvent residual acetamide is 107ppm, and the Dv(90) is controlled to be 40μm. The solubility of the florfenicol crystals prepared by this method in wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com