Immobilized ionic liquid magnetic functional material and method for preparing same

A technology of ionic liquids and functional materials, which is applied in the field of immobilized ionic liquid magnetic functional materials and their preparation, can solve the problems that it is difficult to meet the requirements of ionic liquid catalysts, there are few types, and the performance of ionic liquid functional materials needs to be improved, so as to achieve easy separation Effects of recycling, easy separation, easy washing and drying transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

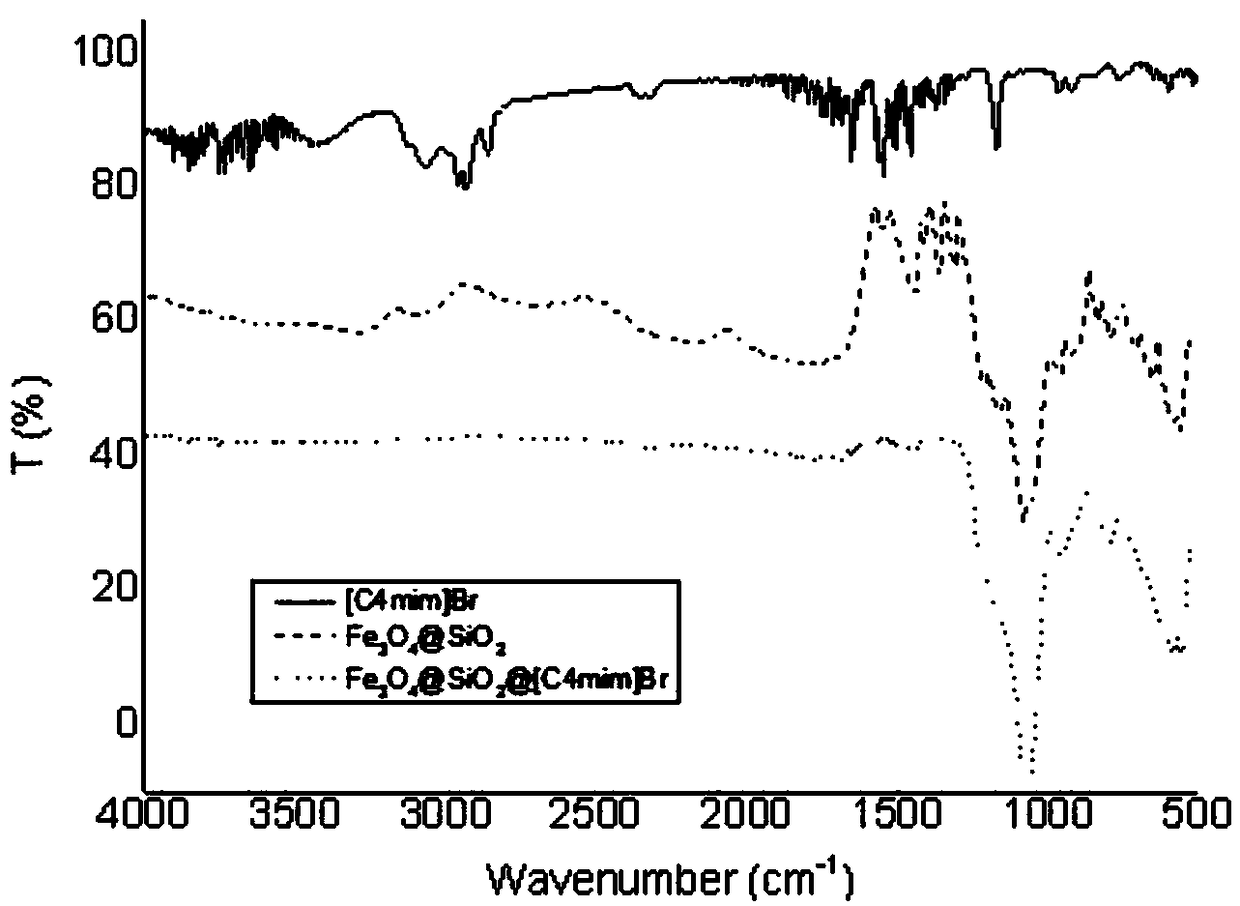

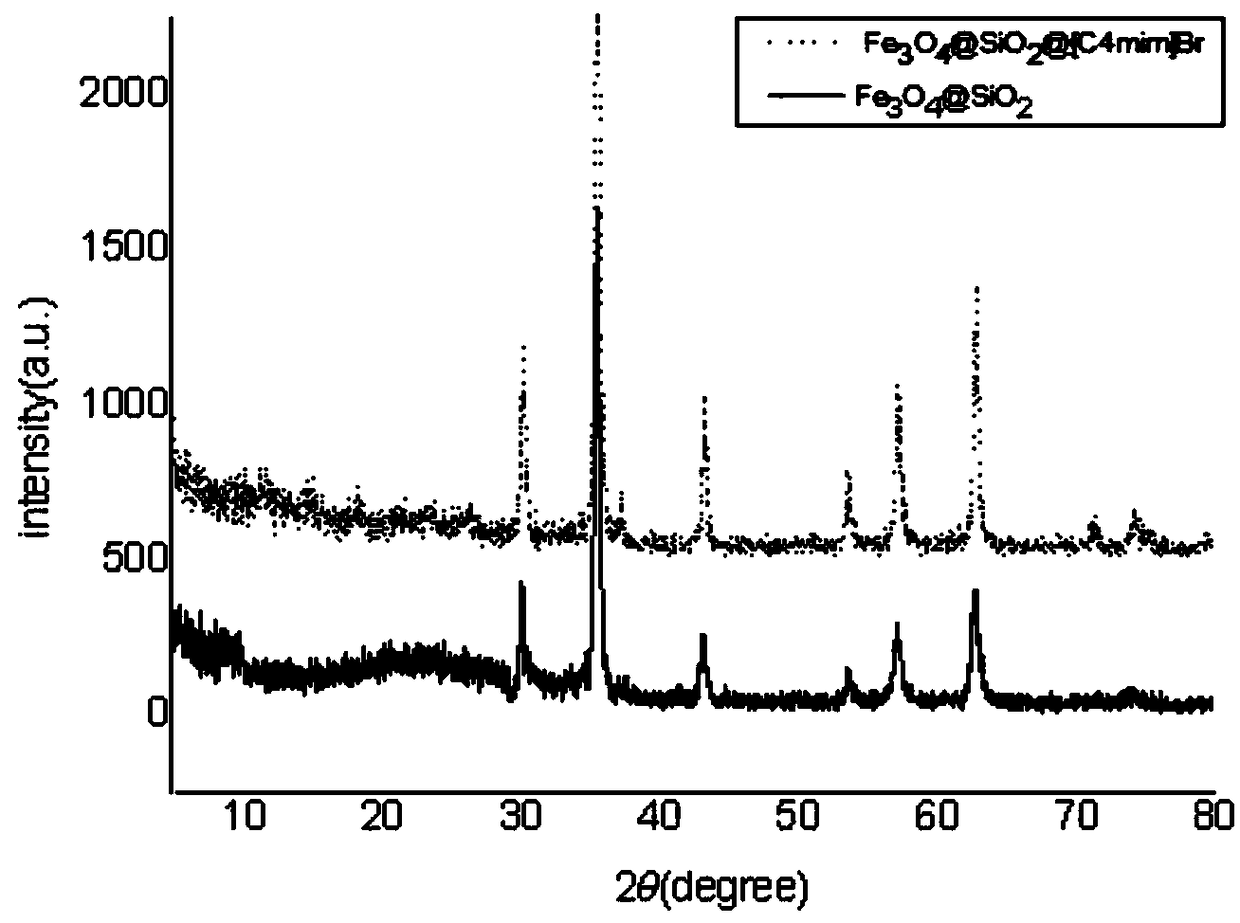

[0031] The present invention provides a preparation method of immobilized ionic liquid magnetic functional material, including the following steps:

[0032] (1) Under ultrasonic conditions, the Fe 3 O 4 Mix with ethanol to get Fe 3 O 4 Dispersions;

[0033] (2) The Fe 3 O 4 The dispersion is mixed with ethyl orthosilicate, ammonia and water, and hydrolyzed under stirring conditions to obtain Fe 3 O 4 @SiO 2 Particles

[0034] (3) The Fe 3 O 4 @SiO 2 The particles are mixed with vinyl triethoxy silane, and the surface is functionalized under the catalysis of triethylamine to obtain Fe 3 O 4 @SiO 2 @VTEs particles;

[0035] (4) The Fe 3 O 4 @SiO 2 @VTEs particles are mixed with ionic liquid, azobisisobutyronitrile, and a chlorine-containing organic solvent, and subjected to coupling treatment under stirring conditions to obtain a solid-supported ionic liquid magnetic functional material.

[0036] In the present invention, under ultrasonic conditions, Fe 3 O 4 Mix with ethanol to get Fe 3 ...

Example Embodiment

[0047] Example 1

[0048] 1.50g Fe 3 O 4 Mixed with 400mL ethanol and added to a 500mL three-necked flask, the mixture was sonicated for 10min under the condition of ultrasonic power of 200W. Add 60mL of water, 30mL of ammonia and 5mL of ethyl orthosilicate (TEOs) to the above mixture in sequence, and carry out the hydrolysis reaction for 5h under stirring at room temperature, the speed of the stirrer is 350r / min, and the obtained hydrolysate is successively used with ethanol and distilled water Repeated washing, applying an external magnetic field for magnetic separation, and then vacuum drying the obtained solid material at 35°C for 5 hours to obtain Fe 3 O 4 @SiO 2 Particles

[0049] 3.00g Fe 3 O 4 @SiO 2 The particles and 10 mmol vinyl triethoxy silane (VTEs) were mixed and put into a 250 mL three-necked flask. Under the catalysis of 40 mL of triethylamine, the reaction was refluxed and condensed in an oil bath at 110°C for 12 hours to perform surface functional modification. T...

Example Embodiment

[0051] Example 2

[0052] Put 150g Fe 3 O 4 Mix with 40L ethanol, and the mixture is sonicated for 20min under the condition of ultrasonic power of 200W. 6L of water, 3L of ammonia and 500mL of ethyl orthosilicate (TEOs) were sequentially added to the above mixed solution, and the hydrolysis reaction was carried out under stirring conditions at room temperature for 6h, and the rotation speed of the stirrer was 450r / min. The obtained hydrolysate was washed repeatedly with ethanol and distilled water successively, applied an external magnetic field for magnetic separation, and then the obtained solid material was vacuum dried at 40°C for 8 hours to obtain Fe 3 O 4 @SiO 2 Particles

[0053] 300g Fe 3 O 4 @SiO 2 Mix with 1 mol of vinyl triethoxy silane (VTEs), catalyzed by 4L triethylamine, reflux and condense in an oil bath at 110°C for 24 hours to perform surface functional modification. The modified product is repeatedly washed with ethanol to remove impurities. Magnetic field sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com