Sewage processing control system and sewage processing method

A sewage treatment and control system technology, applied in water treatment parameter control, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of untimely water quality monitoring feedback, unstable effluent COD and effluent ammonia nitrogen values And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

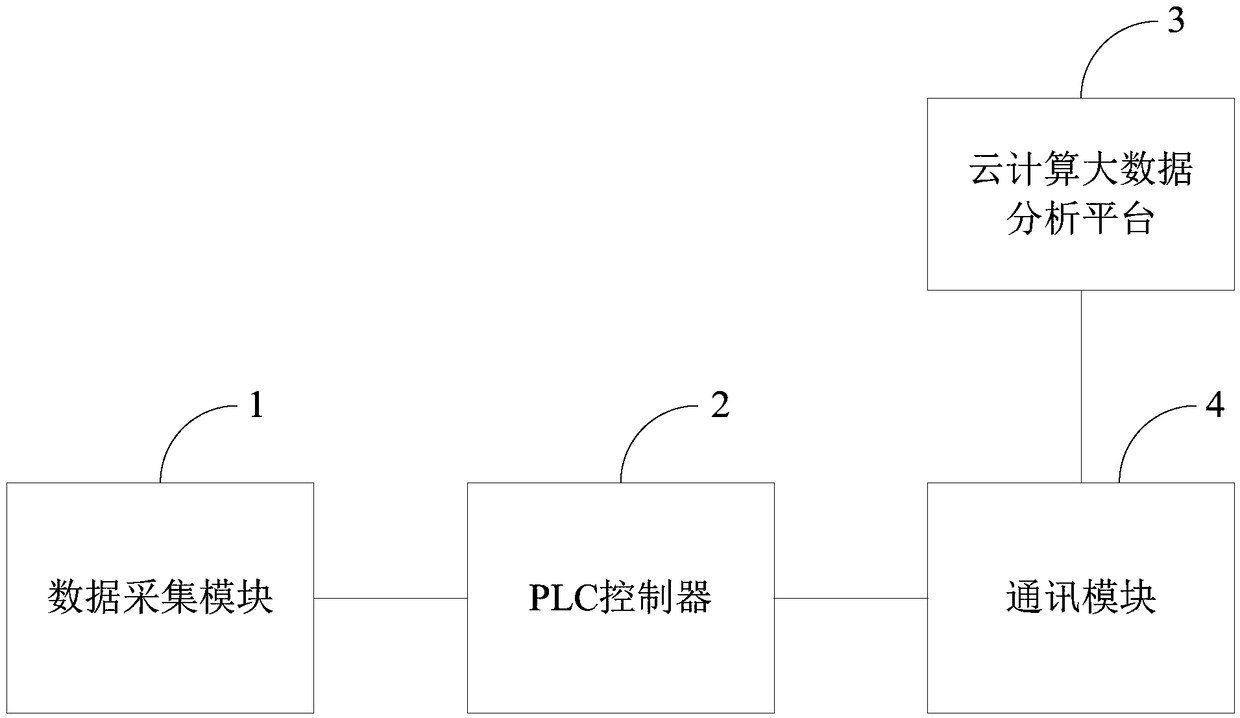

[0053] see figure 1 , figure 1 It is a structural schematic diagram of a sewage treatment control system provided in the embodiment of this application. Depend on figure 1 It can be seen that the sewage treatment control system in this application mainly includes: a data acquisition module 1, a PLC controller 2, a cloud computing big data analysis platform 3 and a communication module 4. Wherein, the data acquisition module 1 is set in the integrated sewage treatment equipment, and is used for collecting COD value, ammonia nitrogen value of water in the sewage treatment process, power parameters and water flow of the integrated sewage treatment equipment. The PLC controller 2 is connected to the cloud computing big data analysis platform 3 through the communication module 4, and the PLC controller 2 is also connected to the electric valve of the dosing tank in the integrated sewage treatment equipment for the data collection module 1. Perform preliminary processing and on-s...

Embodiment 2

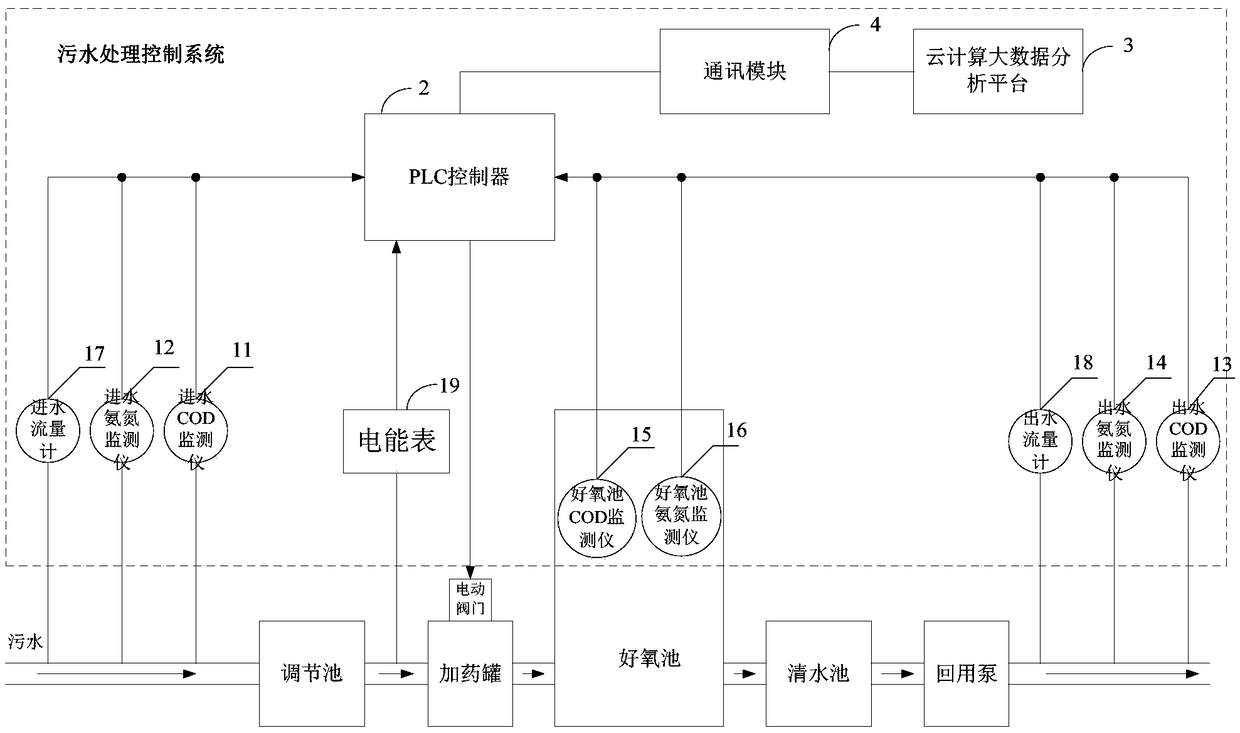

[0057] exist figure 1 On the basis of the illustrated embodiment see figure 2 , figure 2 It is a schematic structural diagram of another sewage treatment control system provided in the embodiment of the present application. Depend on figure 2 It can be seen that the data acquisition module 1 in this embodiment mainly includes: an influent COD monitor 11, an influent ammonia nitrogen monitor 12, an effluent COD monitor 13, an effluent ammonia nitrogen monitor 14, an aerobic pool COD monitor 15, an aerobic pool Ammonia nitrogen monitor 16, water inlet flow meter 17, water outlet flow meter 18 and electric energy meter 19.

[0058] The inlet water COD monitor 11, the inlet water ammonia nitrogen monitor 12 and the inlet water flowmeter 17 are all arranged on the pipeline where the sewage enters the adjustment tank, that is, the pipeline upstream of the adjustment tank. In this embodiment, in order to avoid the interference of the water inlet flowmeter 17 by other equipment...

Embodiment 3

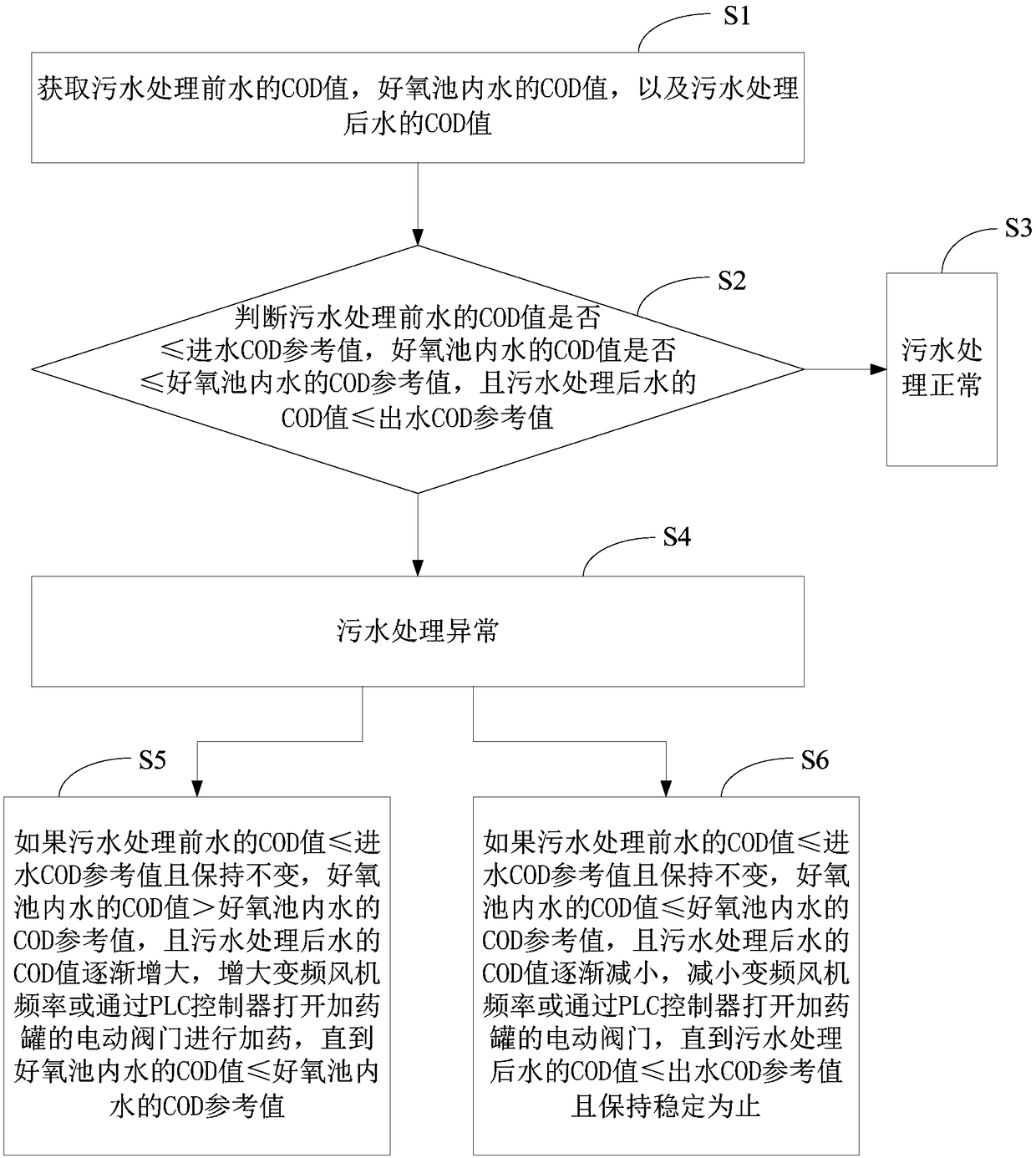

[0069] exist figure 1 and figure 2 On the basis of the illustrated embodiment see image 3 , image 3 It is a schematic flow chart of a sewage treatment method provided in the embodiment of this application. Depend on image 3 It can be seen that the sewage treatment method in this implementation mainly includes the following processes:

[0070] S1: Obtain the COD value of the water before sewage treatment, the COD value of the water in the aerobic pool, and the COD value of the water after sewage treatment.

[0071] In this implementation, after the COD values of water in different water treatment stages are obtained, they are also stored and real-time curves are generated for intuitive understanding.

[0072] S2: Determine whether the COD value of the water before sewage treatment is ≤ the COD reference value of the influent water, whether the COD value of the water in the aerobic pool is ≤ the COD reference value of the water in the aerobic pool, and whether the COD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com