A portable ultrasonic cleaning device

A washing device and portable technology, applied in the field of washing, can solve the problems of poor cleaning effect, attenuation of ultrasonic energy, long laundry time, etc., and achieve the effects of improving decontamination effect, reducing energy attenuation and occupying less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

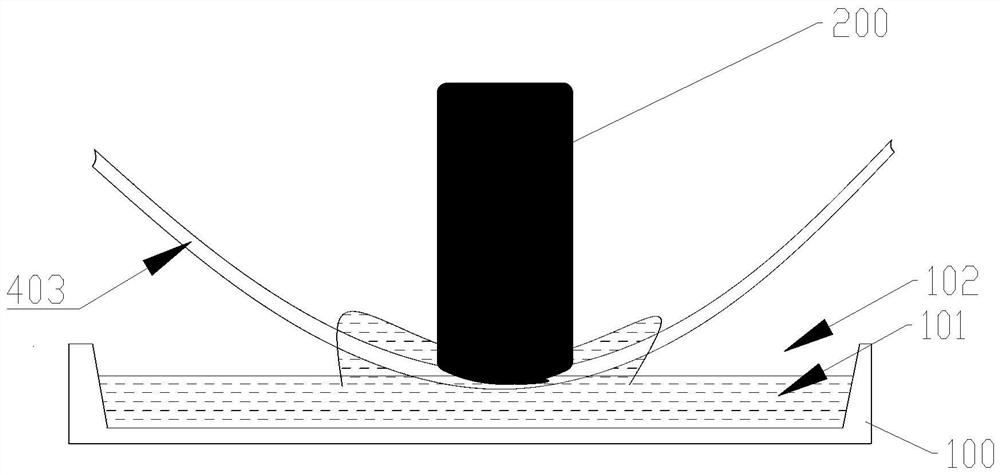

[0040] Such as figure 1 As shown, a portable ultrasonic washing device includes a washing tank 100 for soaking the to-be-washed parts of the laundry 403 and an ultrasonic generator 200 arranged above the washing tank 100. Between the washing tank 100 and the ultrasonic generating device 200 spaced at a certain distance,

[0041] During washing, the laundry 403 is located between the washing tank 100 and the ultrasonic generator 200, the upper part of the laundry 403 is in contact with the ultrasonic generator 200, and the lower part is in contact with the liquid in the washing tank 100.

[0042] After washing, the ultrasonic generator 200 is stored in the washing tank 100 .

[0043] The ultrasonic generating device has an ultrasonic vibration end 202-1. When washing, the laundry 403 is located between the washing tank 100 and the ultrasonic vibration end 202-1, and the upper part of the laundry 403 is in contact with the ultrasonic vibration end 202-1. The lower part is in c...

Embodiment 2

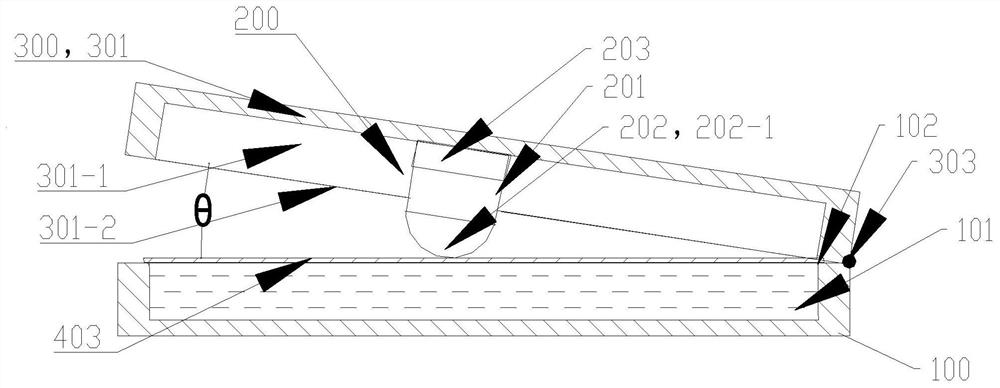

[0056] Such as Figure 2-3 As shown, this embodiment is a further limitation to Embodiment 1. The upper end of the support structure 300 is connected with the ultrasonic generator 200, the ultrasonic generator 200 is fixed on the support structure 300, and the lower end is movably connected with the washing tank 100, so that the support structure 300 can drive the ultrasonic generator 200 to move. When the washing is completed, the support structure 300 is moved to the washing tank 100, so that the ultrasonic generator 200 enters the washing tank 100, and the ultrasonic generating device 200 is stored in the washing tank 100.

[0057] Further, the support structure 300 is rotationally connected with the washing tank 100 through a rotating mechanism. When the washing is completed, the support structure 300 rotates toward the washing tank 100, and the support structure 300 drives the ultrasonic generating device 200 to move, and the support structure 300 and the washing tank The...

Embodiment 3

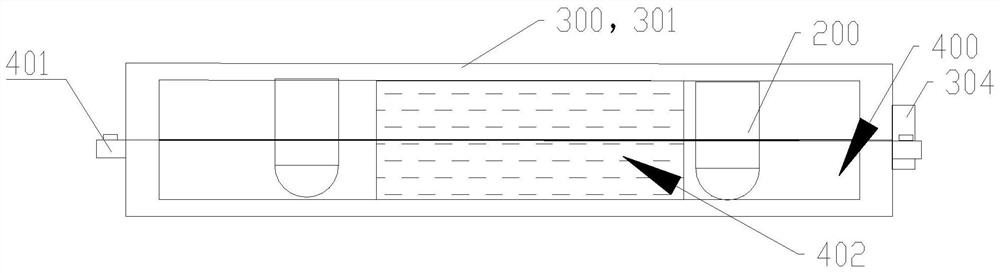

[0074] Such as Figure 4 As shown, this embodiment is a further limitation of Embodiment 1. The upper part of the support structure 300 is connected to the ultrasonic generating device 200, and the lower end is connected to the washing tank 100, and the ultrasonic generating device 200 is supported above the sink. The supporting structure 300 The length can be adjusted. After washing, the length of the support structure 300 is shortened to store the ultrasonic generator 200 in the washing tank 100 .

[0075] The length of the support structure 300 is adjustable. After washing, the support structure 300 is shortened, and the ultrasonic generator 200 fixed on the support structure 300 is stored in the washing tank 100. When washing, the shortened support structure 300 is elongated, and the ultrasonic generating device 200 fixed on the supporting structure 300 protrudes from the washing tank 100 , and the supporting structure 300 supports it above the washing tank 100 .

[0076]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com