Planetary gear transmission device with small tooth difference and decelerator

A planetary and gear transmission technology with less tooth difference, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of parts wear and complex structure, etc., and achieve the effect of long working life, large contact area and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

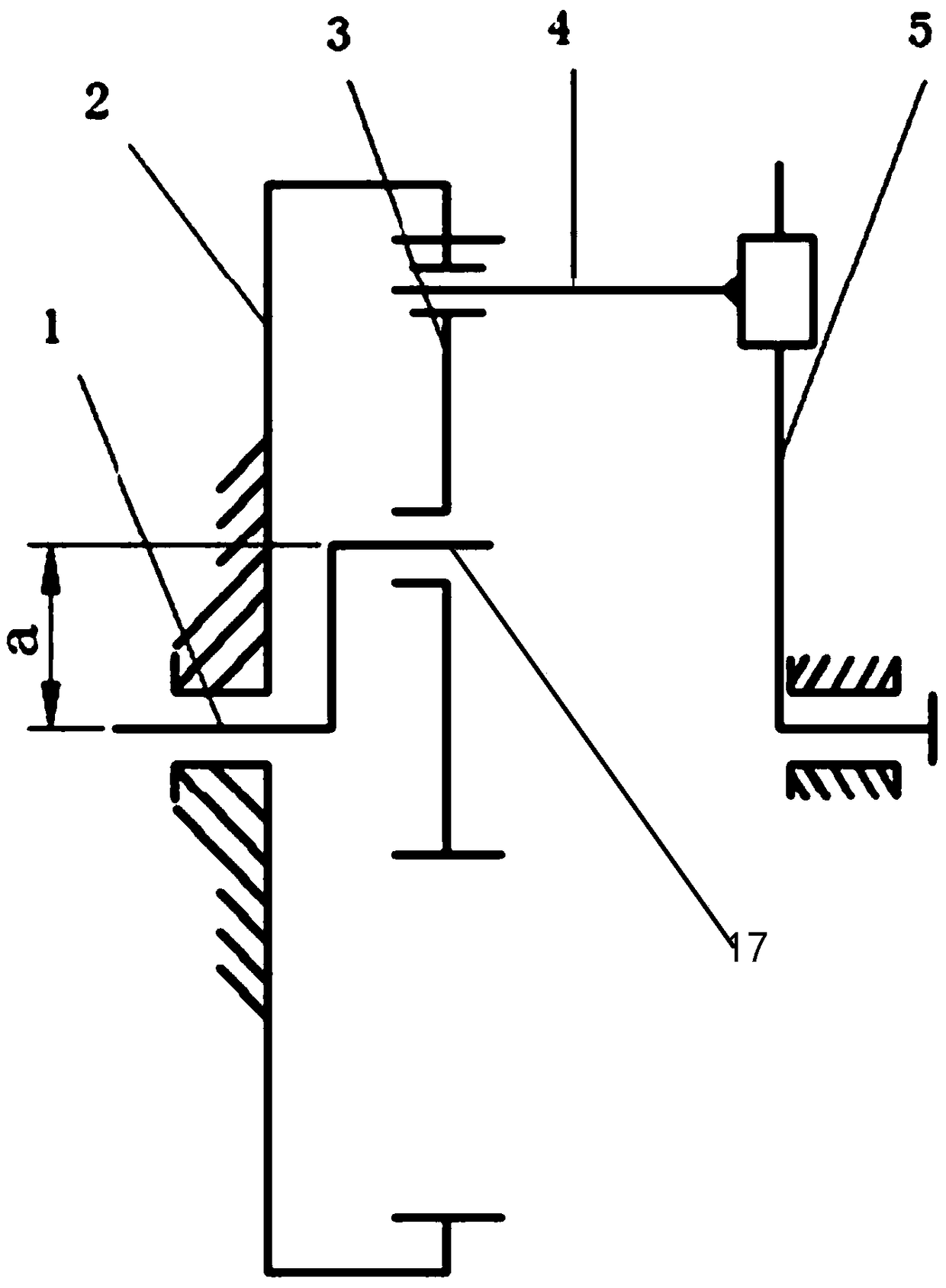

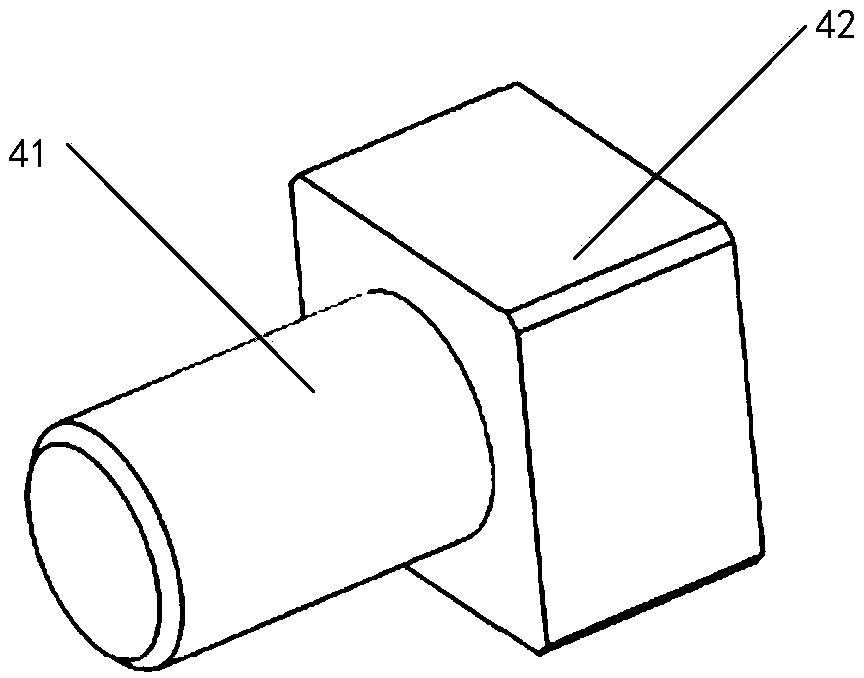

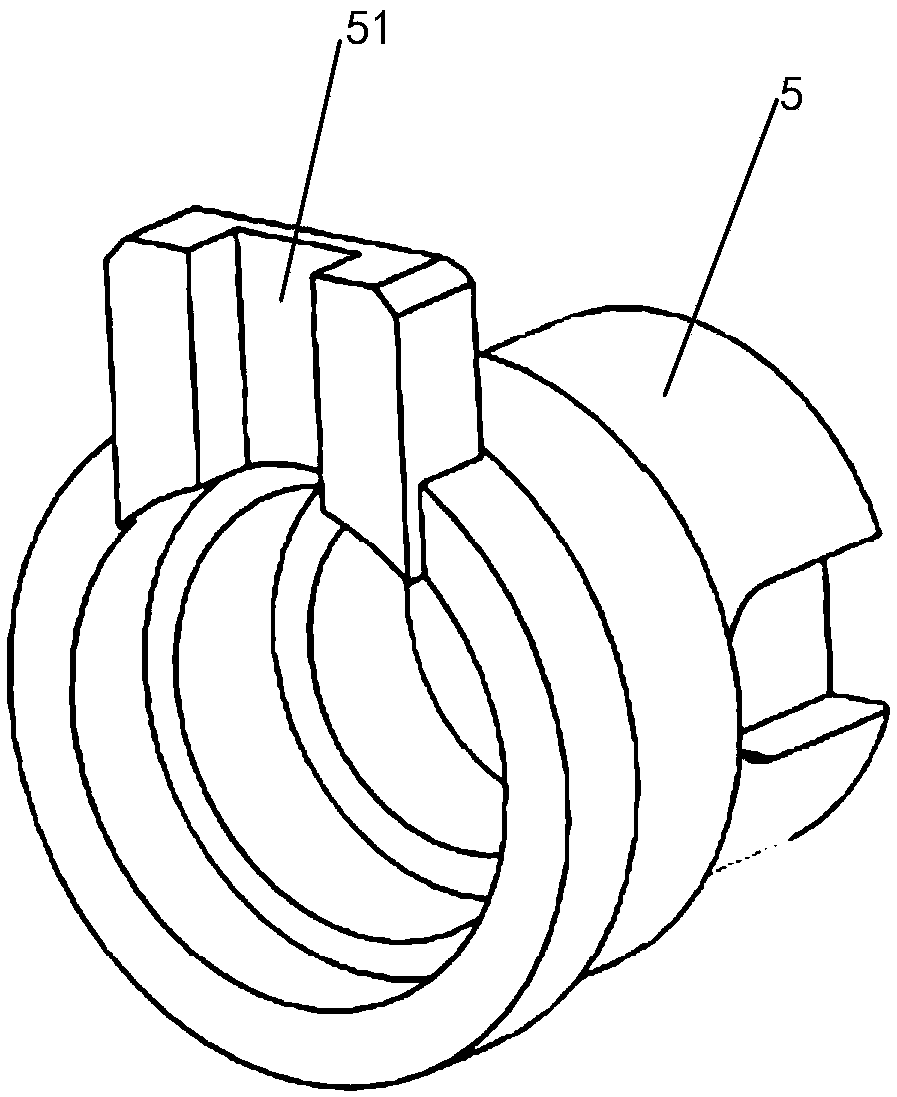

[0032] refer to Figure 1 to Figure 3 , the present invention provides a planetary gear transmission with small tooth difference, comprising an input shaft 1 for connecting to an external driving device and an output shaft 5 for connecting to an external driven device, the rotation axis of the input shaft 1 and The rotation axes of the output shaft 5 are collinear, and the input shaft 1 is sleeved with an eccentric journal 17, which also includes: an inner ring gear 2, which is fixed on the housing; a planetary gear 3, which is mounted on the On the eccentric journal 17; the planetary gear 3 and the ring gear 2 form an internal meshing gear pair; the planetary gear 3 is provided with a mounting hole in the axial direction; the transmission part 4 is installed on the one end of the In the mounting hole, the other end is installed on the output shaft 5; the transmission member 4 and the planetary gear 3 form a rotating pair, and the transmission member 4 and the output shaft 5 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com