Test system and method for joint destruction effect of laser and surface airflow

A test system and airflow technology, applied in the field of laser applications, can solve the problems of narrow application range, large volume, high cost of the test system, etc., and achieve the effect of wide application range, small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

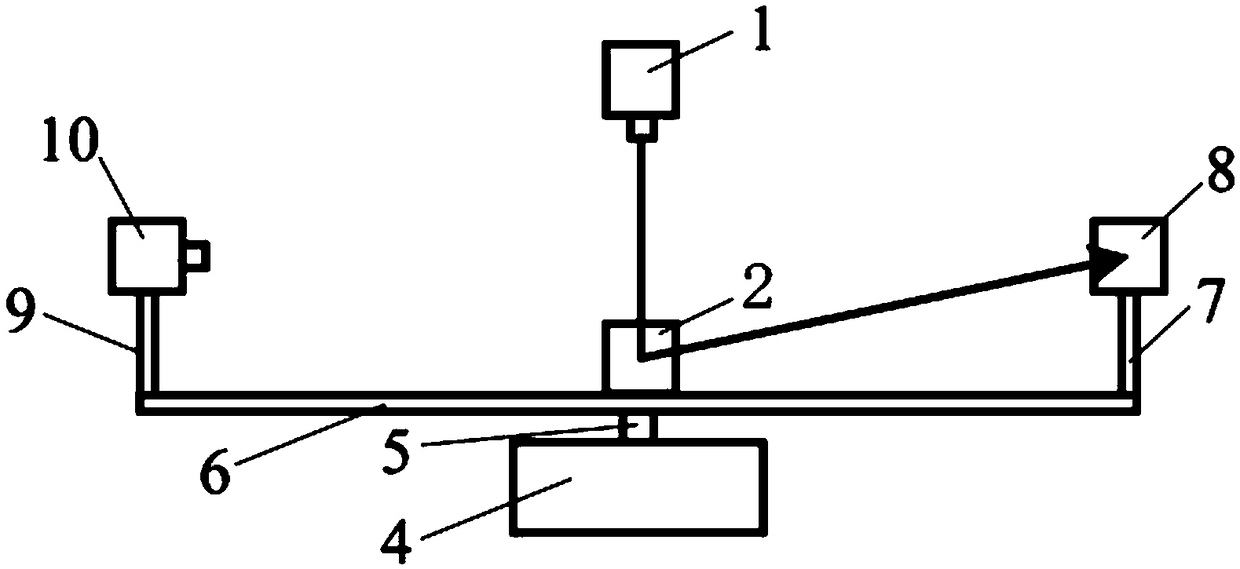

[0033] see figure 1 and image 3 , a test system for the combined destructive effect of laser and surface airflow, including a target 8, a beam module, an airflow simulation module and a monitoring device 10, the beam module includes a laser 1 and a first total reflection mirror 2, and the first total reflection mirror 2 is set on the exit optical path of the laser 1; the airflow simulation module includes a rotating support assembly, the rotation support assembly includes a motor 4 and a support assembly, and the motor shaft 5 is fixedly connected to the middle of the support assembly; the optical axis of the laser 1 exits through the Through the center of the first total reflection mirror 2 and the axis of the motor rotating shaft 5.

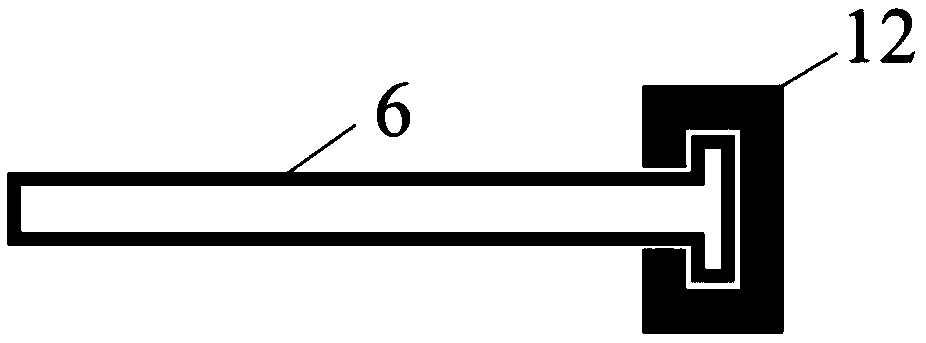

[0034] The support assembly includes a rotating rod 6 and a target support rod 7 and a monitoring equipment support rod 9 vertically installed at the two ends of the rotating rod 6. The first full reflection mirror 2 is fixed on the middle pa...

Embodiment 2

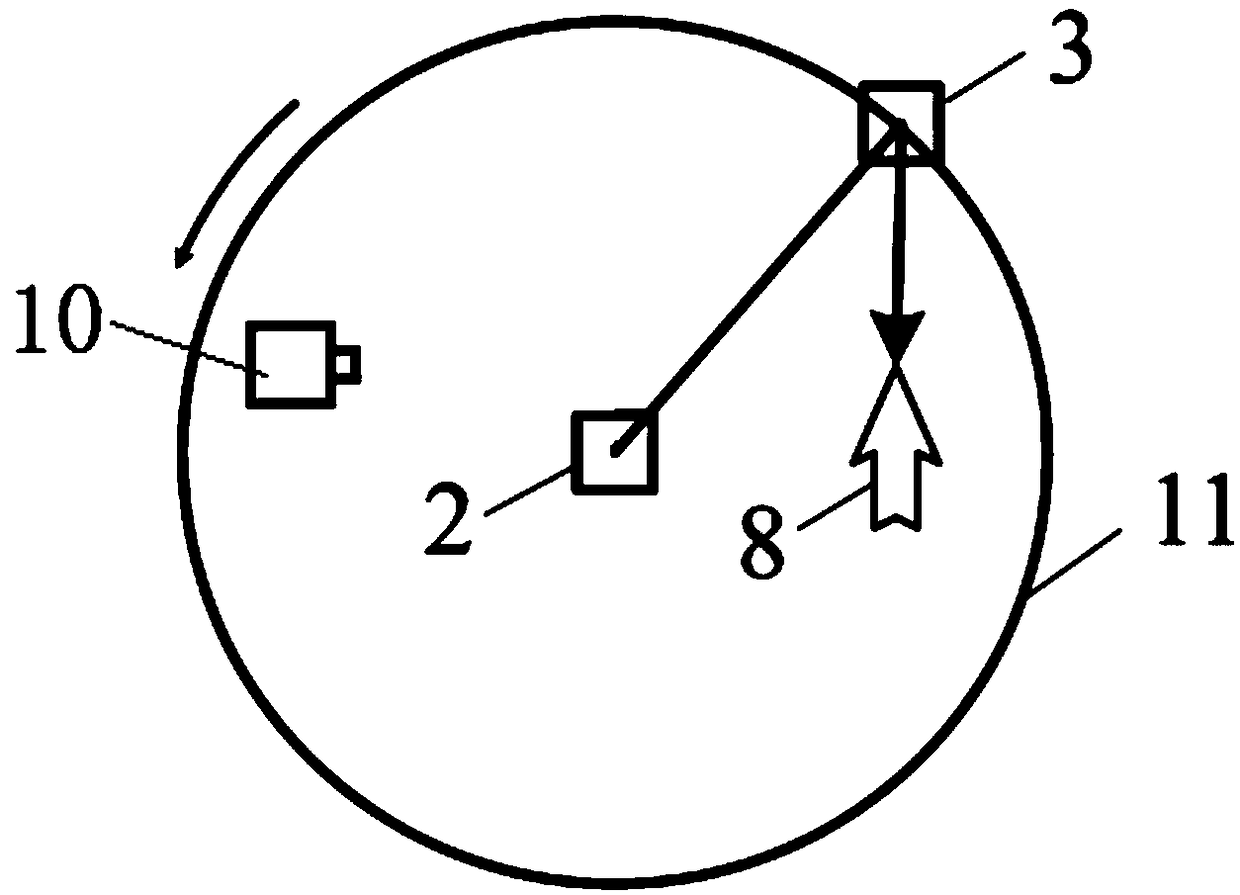

[0044] see figure 2 , a test system for the combined destructive effect of laser and surface airflow, including a target 8, a beam module, an airflow simulation module and a monitoring device 10, the beam module includes a laser 1 and a first total reflection mirror 2, and the first total reflection mirror 2 is set on the exit optical path of the laser 1; the airflow simulation module includes a rotating support assembly, the rotation support assembly includes a motor 4 and a support assembly, and the motor shaft 5 is fixedly connected to the middle of the support assembly; the optical axis of the laser 1 exits through the Through the center of the first total reflection mirror 2 and the axis of the motor rotating shaft 5.

[0045] The support assembly includes a turntable 11 and a target pole 7 and a monitoring equipment pole 9 installed on the outer edge of the turntable 11, the first total reflection mirror 2 is fixed at the center of the turntable 11, and the target 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com