Method for detecting blending proportion of components in cut tobacco

A shredded tobacco and proportioning technology, which is applied in measuring devices, analyzing materials, and analyzing materials through optical means, can solve the problems of components whose mixing uniformity difference cannot be known, the application range is limited, and the operation is cumbersome, etc., to achieve Good practical value and promotion and application significance, improved stability and accuracy, and simple scanning method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

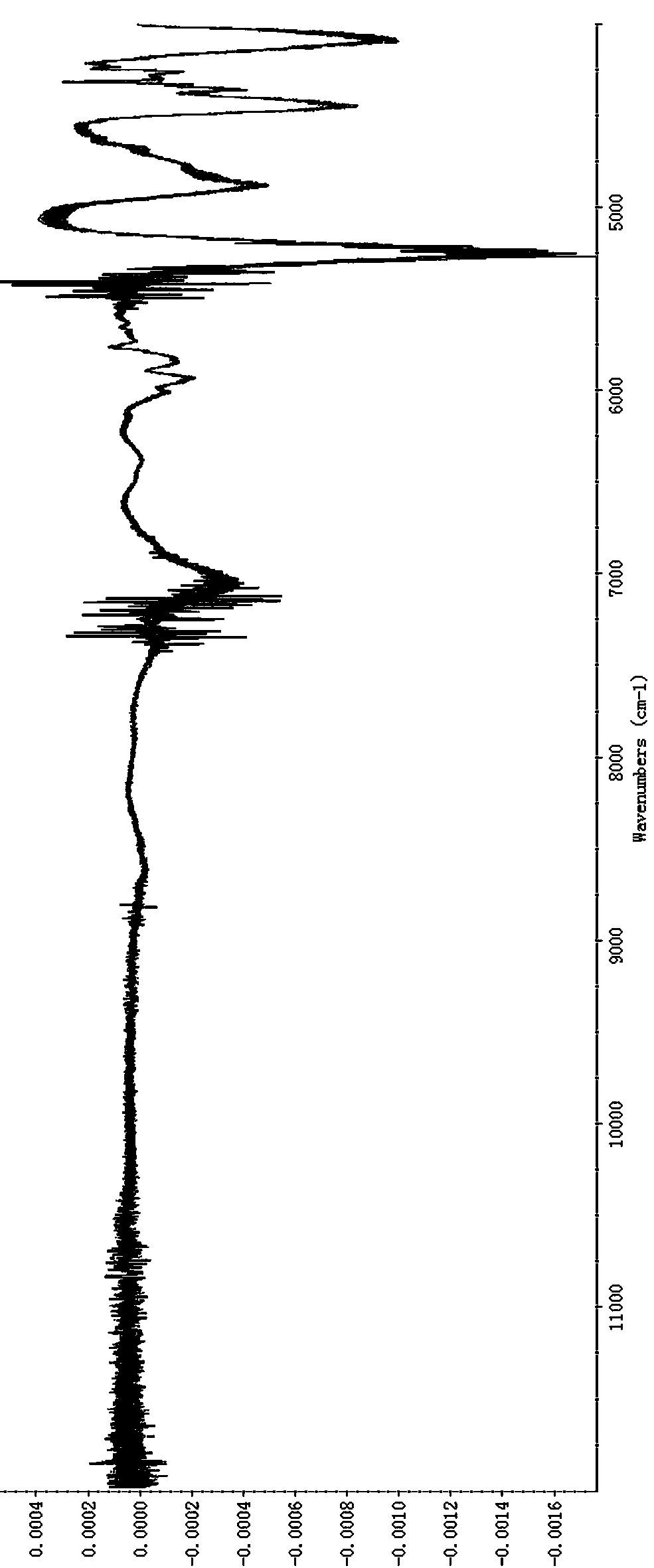

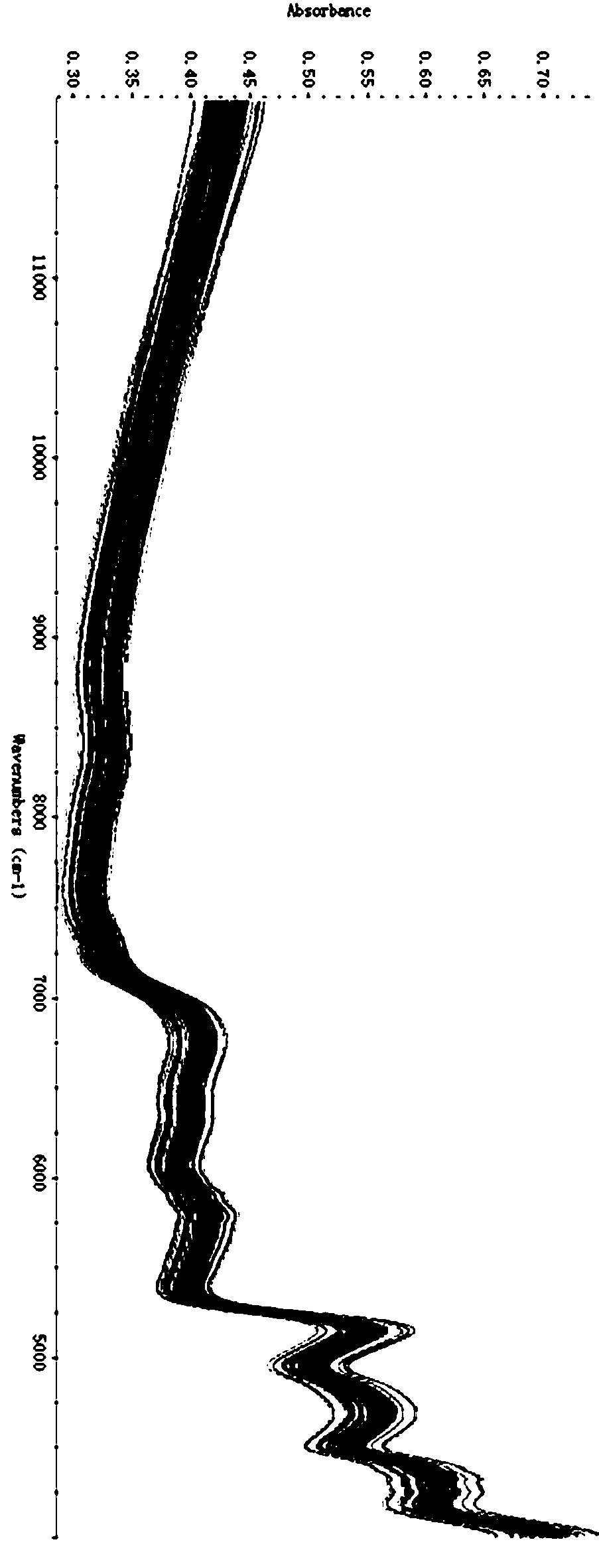

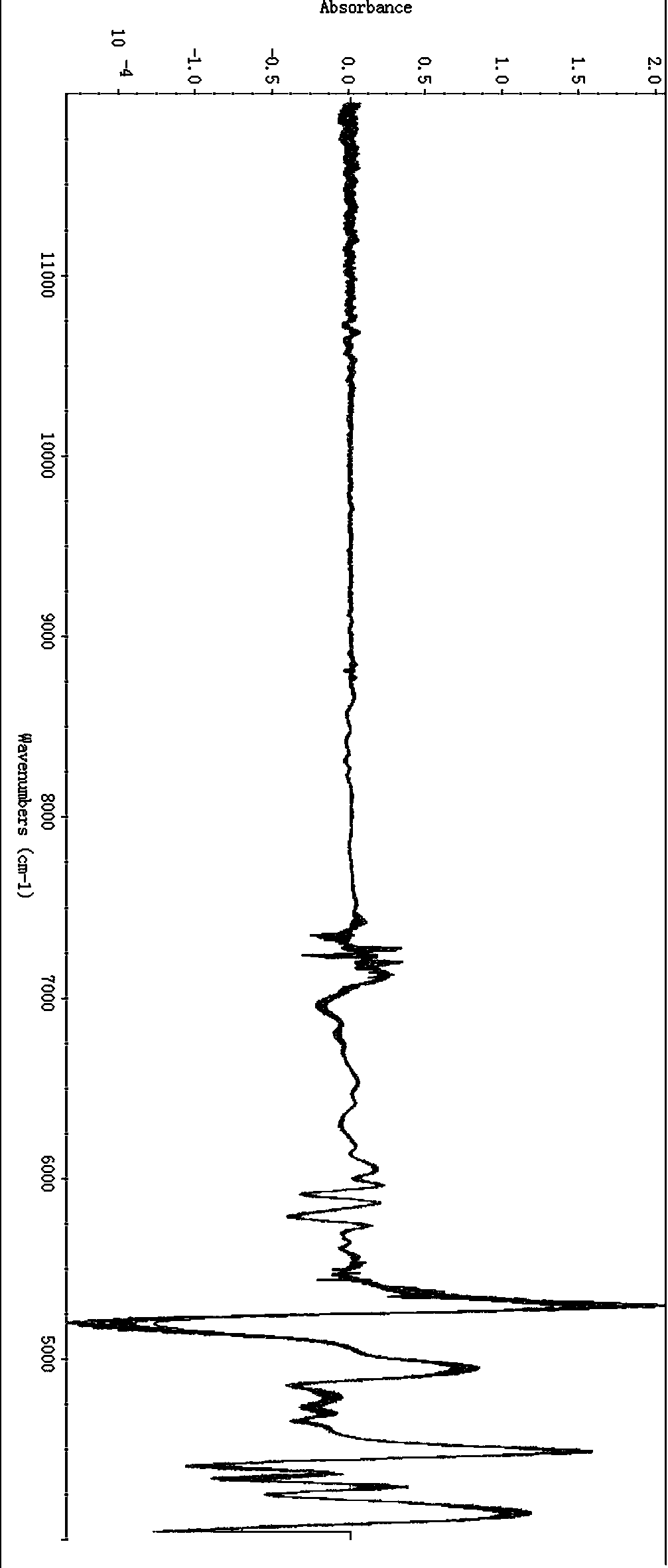

Image

Examples

Embodiment 1

[0060] Since the preparation of multi-component shredded tobacco samples is relatively complicated, this example only takes two kinds of shredded tobacco components (shredded leaves + shredded stems) as examples, and briefly introduces the method for detecting the blending ratio of each component in shredded tobacco provided by this application as follows .

[0061] (1) Pretreatment of each component sample of shredded tobacco and construction of calibration set samples

[0062] Take an appropriate amount of shredded leaves and shredded stems, spread them on trays, put them in an oven and bake them at 40°C for 4 hours, then put them into sealed bags and store them for later use.

[0063] According to the needs of cigarette products, reasonably set the limit value of the blending ratio of each component (the blending ratio of shredded stems is set between 10% and 40% in this example) and the change gradient (the design of this example uses an equal gradient of 2% ) and prepare...

Embodiment 2

[0105]The method for detecting the blending ratio of shredded tobacco provided in this embodiment is generally the same as that in Embodiment 1, only some operations are adjusted. The details of the adjustments and results are as follows.

[0106] In step (2): select the three characteristic chemical components of total plant alkaloids, total sugars, and chlorine as the principal components, and then use SPSS to conduct principal component analysis (the coefficient matrix for calculating the scores of the principal components based on the contents of the three chemical components is shown in Table 2- 1), and output the factor score (which can be calculated by the comprehensive factor score calculation formula (2)). The specific chemical composition content detection and factor scoring results are shown in the following tables 2-2 to 2-6 (tables 2-2 to 2-6 represent the test results of a group of samples respectively);

[0107] Finally, through regression analysis, a linear re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com