A method and implementation system for deviation control of molten iron quantity in converter

A control method and water volume technology, applied in the control/adjustment system, non-electric variable control, liquid level control, etc., can solve the problem that the real-time status information of the iron ladle cannot be grasped and effectively utilized in a timely manner, and cannot meet the requirements of one-key intelligent steelmaking For problems such as the amount of molten iron, it is impossible to automatically control the amount of iron loaded in real time, to achieve the effect of realizing system self-learning, ensuring safety, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be described in further detail with reference to the drawings.

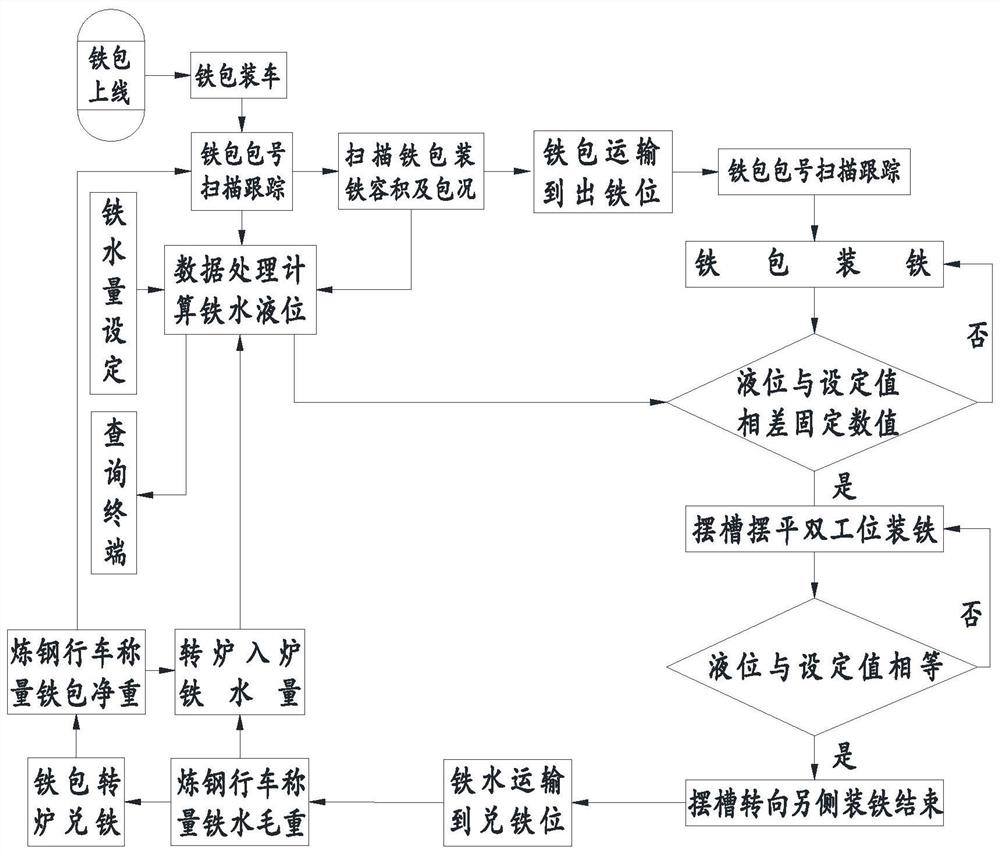

[0031] according to figure 1 The process shown in the converter is incorporated in the process, the steps are as follows:

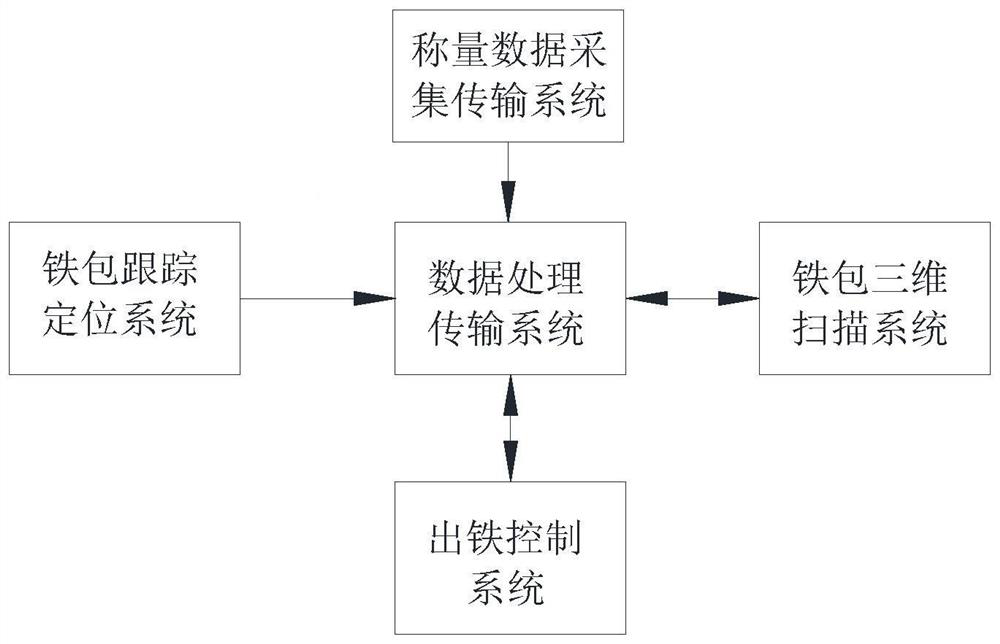

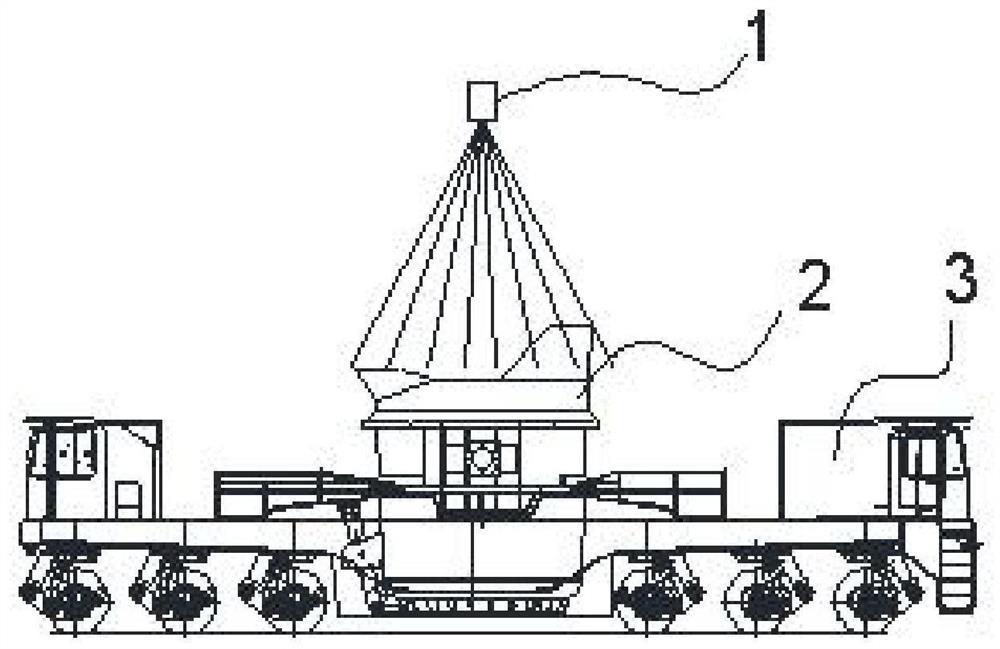

[0032] Step 1, by weighing the data acquisition and transmission subsystem, after the iron bag, the converter is obtained into the iron water transport vehicle 3, and the converter is obtained.

[0033] Step 2, through the iron bag tracking the positioning subsystem to obtain the iron package 2 package number and the iron water transport vehicle No. 3, bundle the data information and the package number, transfer to the data processing transmission system;

[0034] Step 3, through the three-dimensional scanning system, each scanned iron bag 2, iron bag 2, the iron bag 2, the iron bag 2, such as the iron bag, and the harvested iron bag 2, and transmit it to the data processing transmission system;

[0035] Specifically, after the three-dimensional scanning sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com