Preparation method of white tea

A technology for white tea and tea leaves, applied in the field of white tea preparation, can solve problems such as difficulty in meeting daily consumption, unsustainable aroma of white tea, uneven quality, etc., so as to improve the yield of tea leaves, enhance nutritional value and aroma perception, and maintain the quality of tea leaves. The effect of shape integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

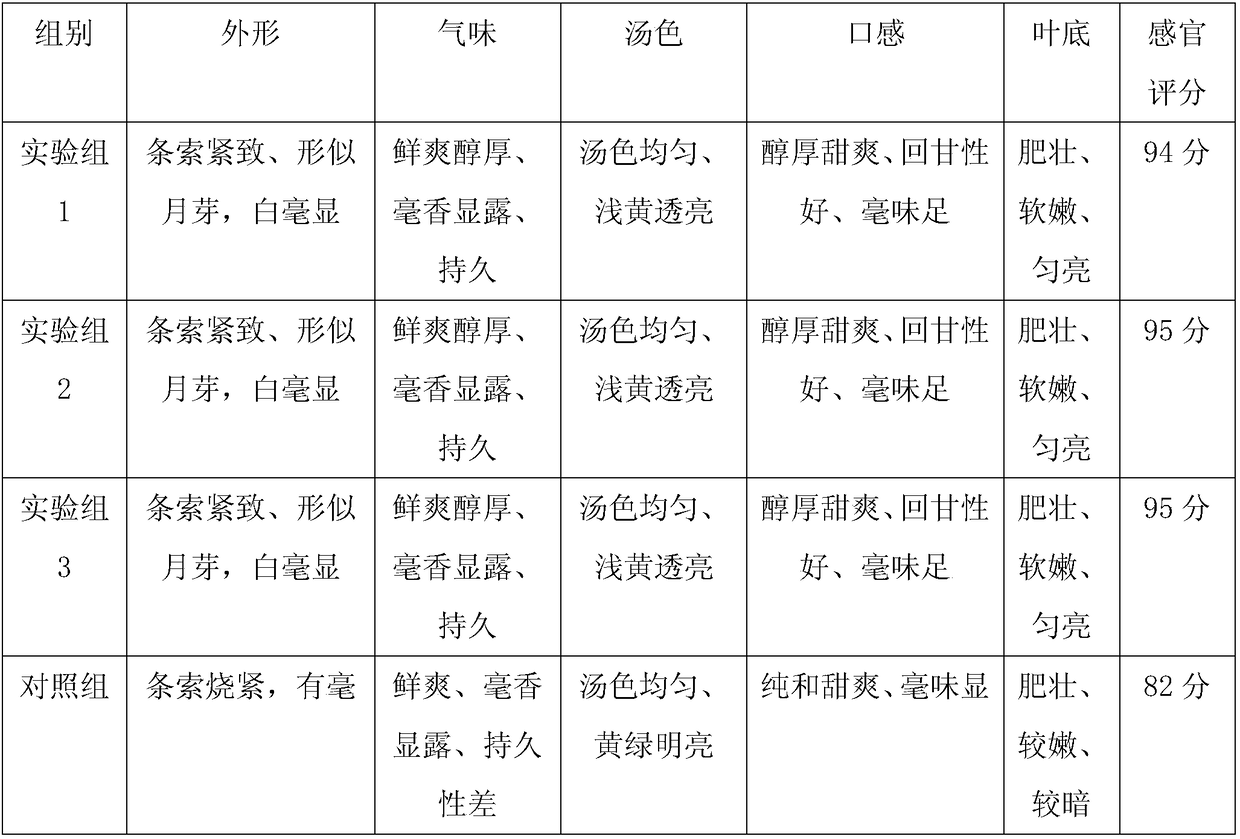

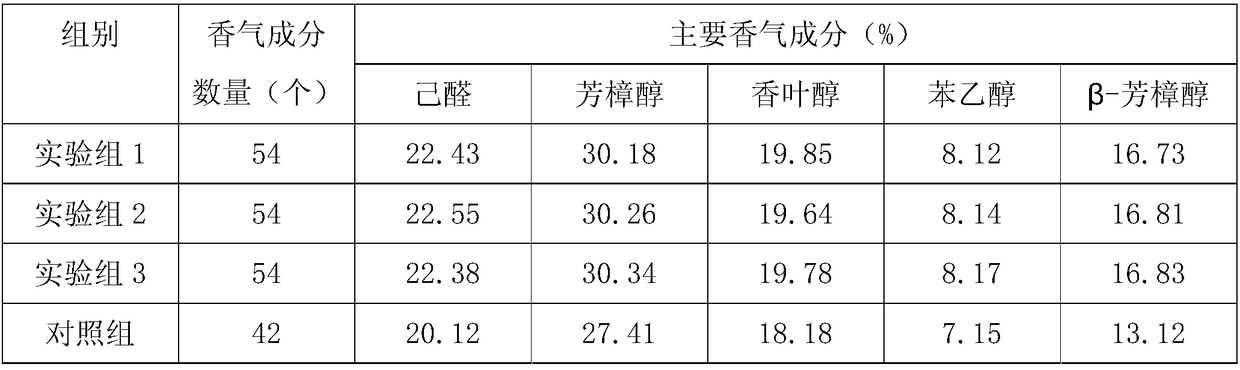

Examples

Embodiment 1

[0025] A preparation method of white tea, comprising the following steps:

[0026] (1) Circular withering and micro-fermentation treatment: extract fresh leaf single buds as tea raw material, spread the tealeaves evenly on the withering tank with a thickness of 8cm, and ventilate and add a wavelength of 540nm, an illumination height of 10cm, and an illumination intensity of 250Lx. After a green light irradiates the tea leaves until they lose 4% of their weight, spread them evenly in a fermentation chamber with a thickness of 10 cm to ferment for 1.5 hours to obtain the first fermented tea leaves;

[0027] Put the first fermented tea leaves into a kneading machine, treat them with a pressure of 10N and a rotating speed of 5r / min for 10min, continue to spread them in the withering tank, continue to ventilate and add a wavelength of 540nm, a light height of 15cm, and a light intensity of 540nm. The second green light of 180Lx is irradiated to the weight loss of the first fermente...

Embodiment 2

[0033] A preparation method of white tea, comprising the following steps:

[0034] (1) Circular withering, micro-fermentation treatment: extract fresh leaf single bud as tea raw material, spread said tealeaves evenly on the withering tank by the thickness of 9cm, ventilation plus wavelength is 545nm, light height is 10cm, and light intensity is 255Lx the first After a green light is illuminated until the tea leaves lose 5% of their weight, they are evenly spread in a fermentation chamber with a thickness of 12 cm and fermented for 1.7 hours to obtain the first fermented tea leaves;

[0035] Put the first fermented tea leaves into a kneading machine, treat them with a pressure of 13N and a speed of 8r / min for 12min, continue to spread them in the withering tank, continue to ventilate and add a wavelength of 545nm, a light height of 15cm, and a light intensity of 545nm. The second green light of 190Lx is irradiated to the weight loss of the first fermented tea leaves by 6%, and ...

Embodiment 3

[0041] A preparation method of white tea, comprising the following steps:

[0042](1) Circular withering, micro-fermentation treatment: extract fresh leaf single bud as tea raw material, spread said tealeaves evenly on the withering tank by the thickness of 10cm, ventilation plus wavelength is 550nm, light height is 10cm, and light intensity is the second day of 260Lx After a green light irradiates the tea leaves to lose 6% of their weight, spread them evenly in a fermentation chamber with a thickness of 15 cm to ferment for 2 hours to obtain the first fermented tea leaves;

[0043] Put the first fermented tea leaves into a kneading machine, treat them with a pressure of 15N and a rotating speed of 10r / min for 15 minutes, continue to spread them in the withering tank, continue to ventilate and add a wavelength of 550nm, a light height of 15cm, and light intensity The second green light of 200 Lx is irradiated to the weight loss of the first fermented tea leaves by 8%, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com