Manufacturing process of crispy and chewy salty oil chicken leaving lingering fragrance in mouth

A production process, a technology of bad oil chicken, applied in the direction of the function of food ingredients, food ingredients as taste improvers, food ingredients as odor improvers, etc., can solve the problem of affecting the taste, not being able to store for a long time, single taste of bad oil chicken, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

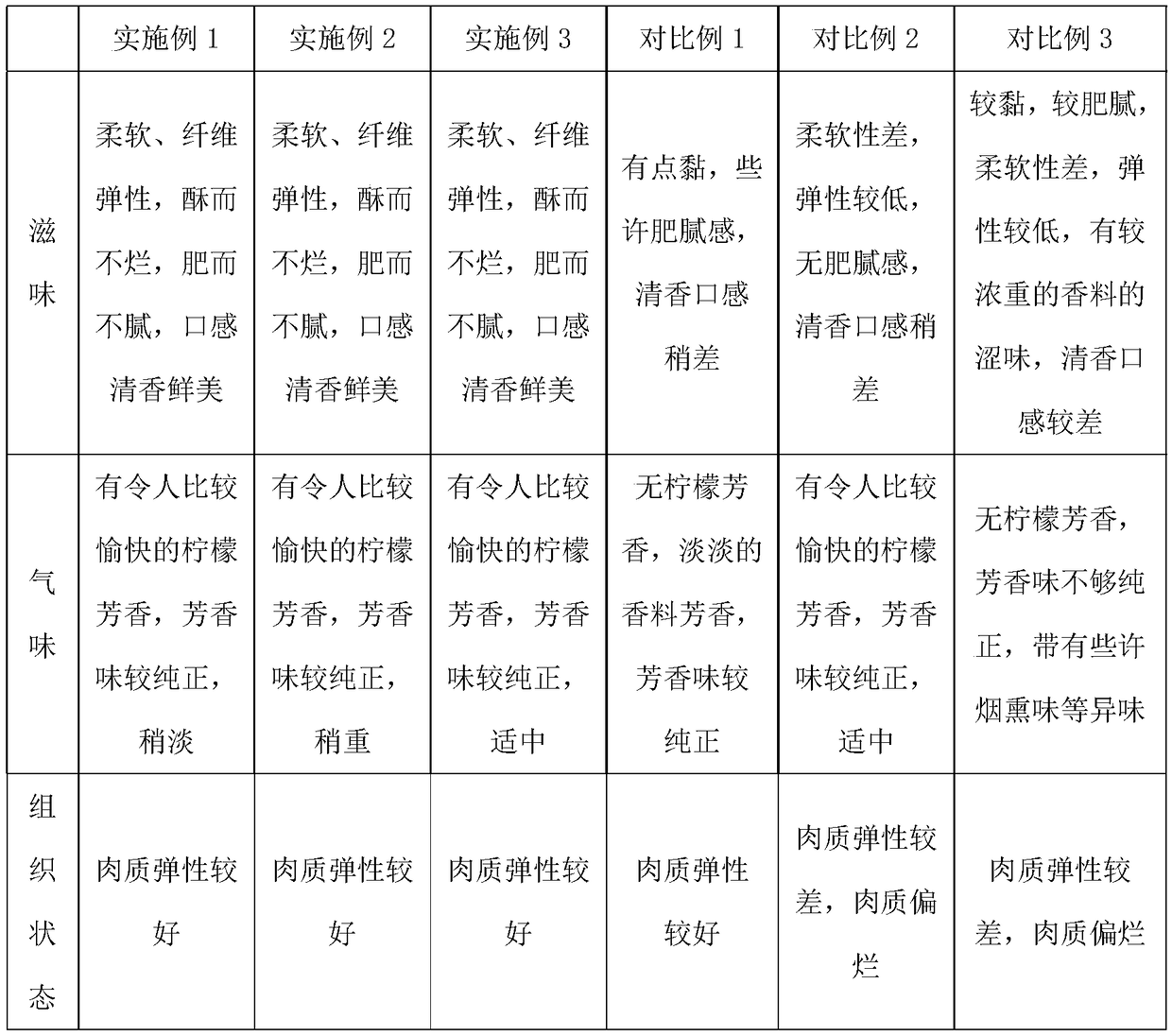

[0061] The invention discloses a production process of crispy but not rotten savory chicken, which comprises the following steps:

[0062] (1) Materials

[0063] Select healthy hens with a chicken age of 360 days, weighing 1.7-2.1kg, after slaughtering, hair removal and evisceration;

[0064] (2) Preparation of soup stock:

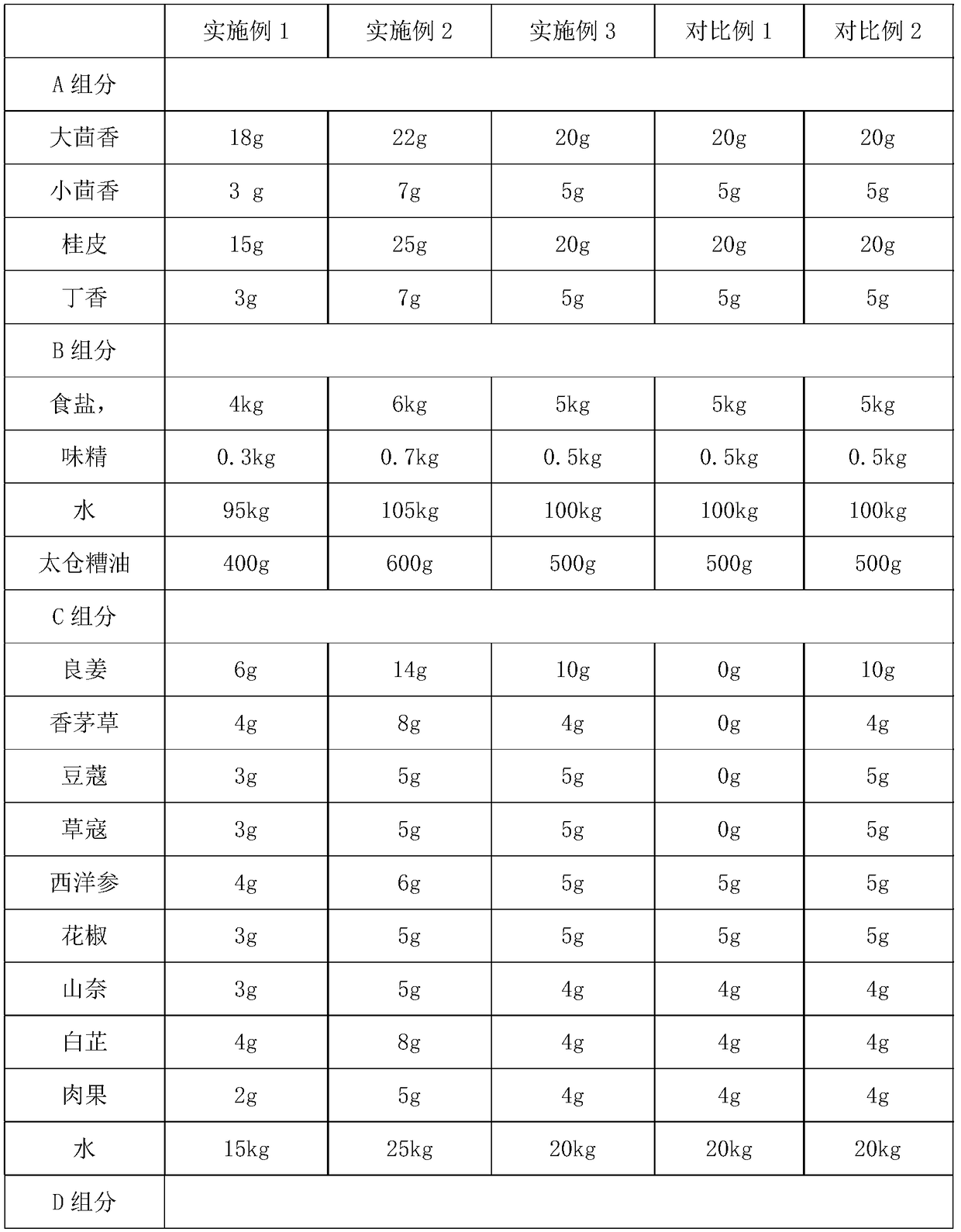

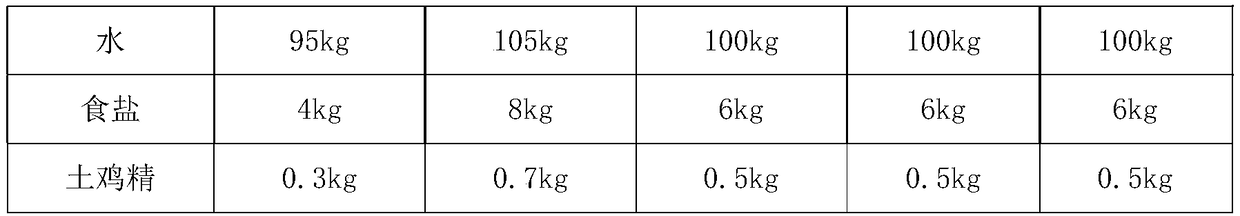

[0065] Prepare component A, component B, component C and component D respectively according to the formula quantity in Table 1;

[0066] (3) Preparation of marinated soup

[0067] Add component A to component B, mix the two soups to make a marinated soup, put 100kg of hen into the marinated soup, arrange it a little, so that the hen is completely immersed in the marinated soup. Marinate below 10°C for 7 hours;

[0068] (4) Cooking

[0069] Mix component C and D to make the cooking soup, take out the marinated hen in step (3) from the marinating soup, put it into the cooking soup and boil it, then simmer over low heat 1.2 hours;

[0070] (5) Vacuum p...

Embodiment 2

[0080] The invention discloses a production process of crispy but not rotten savory chicken, which comprises the following steps:

[0081] (1) Materials

[0082] Select healthy hens with a chicken age of 400 days, weighing 1.7-2.1kg, and remove hair and eviscerate after slaughtering;

[0083] (2) Preparation of soup stock

[0084] Prepare component A, component B, component C and component D respectively according to the formula quantity in Table 1;

[0085] (3) Preparation of marinated soup

[0086] Add component A to component B, mix the two soups to make a marinated soup, put 100kg of hen into the marinated soup, arrange it a little, so that the hen is completely immersed in the marinated soup. Marinate below 10°C for 8 hours;

[0087] (4) Cooking

[0088] Mix component C and D to make the cooking soup, take out the marinated hen in step (3) from the marinating soup, put it into the cooking soup and boil it, then simmer over low heat 1.5 hours;

[0089] (5) Vacuum pa...

Embodiment 3

[0098] The invention discloses a production process of crispy but not rotten savory chicken, which comprises the following steps:

[0099] (1) Materials

[0100] Select healthy hens with a chicken age of 380 days, weighing 1.7-2.1kg, and remove hair and eviscerate after slaughtering;

[0101] (2) Preparation of soup stock

[0102] Prepare component A, component B, component C and component D respectively according to the formula quantity in Table 1;

[0103] (3) Preparation of marinated soup

[0104] Add component A to component B, mix the two soups to make a marinated soup, put 100kg of hen into the marinated soup, arrange it a little, so that the hen is completely immersed in the marinated soup. Marinate below 10°C for 6 hours;

[0105] (4) Cooking

[0106] Mix component C and D to make the cooking soup, take out the marinated hen in step (3) from the marinating soup, put it into the cooking soup and boil it, then simmer over low heat 1 hour;

[0107] (5) Vacuum packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com