MgAl2O4 base intermediate-temperature carbonyl sulfide hydrolysis catalyst and preparation method thereof

A hydrolysis catalyst, spar-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as deficiencies, resistance to oxygen and sulfur poisoning, achieve stable medium temperature activity, reasonable design, and improve resistance The effect of oxygen sulfur poisoning properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

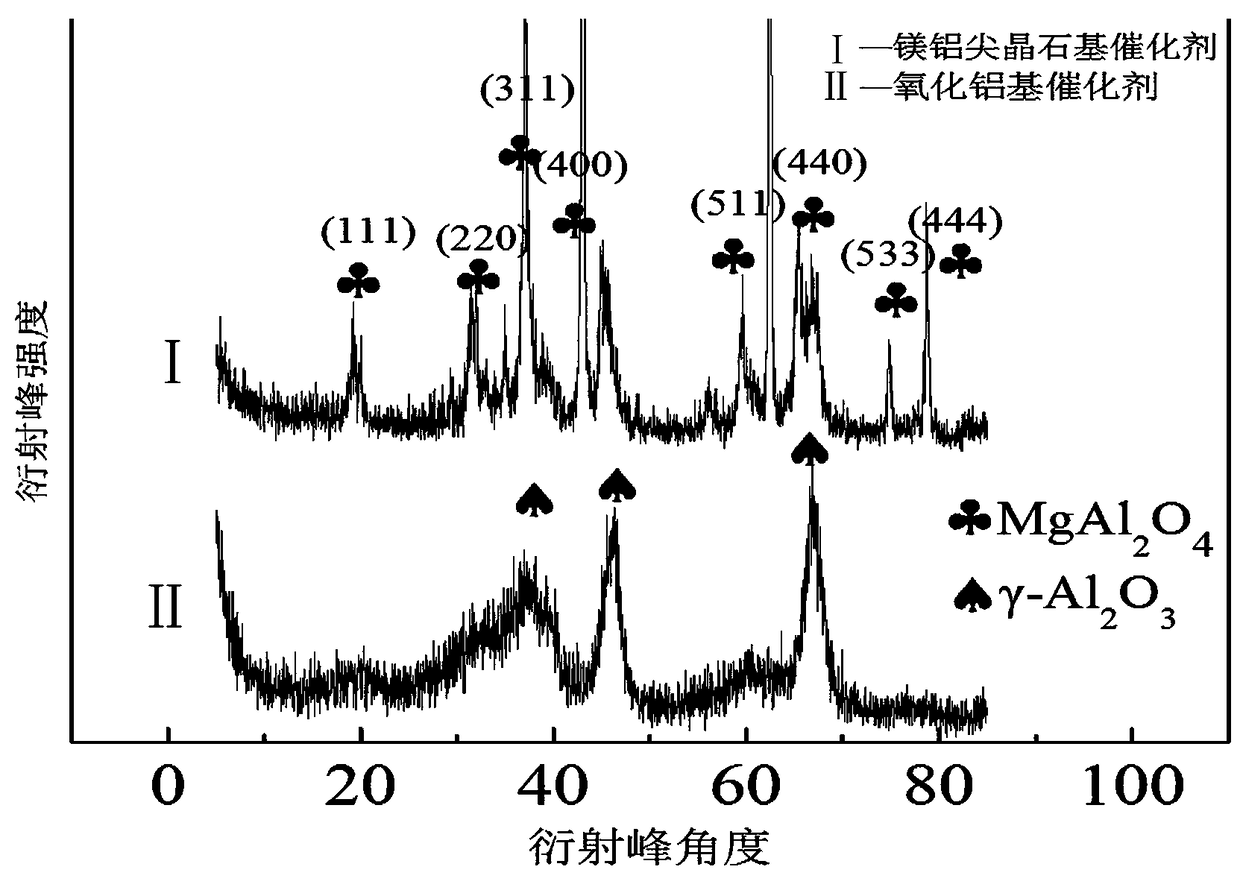

[0022] A kind of preparation method of magnesia-aluminum spinel-based medium-temperature carbonyl sulfide hydrolysis catalyst is as follows:

[0023] (1), 43.07wt.% magnesium carbonate and 56.93wt.% pseudo-boehmite mechanically and uniformly mixed samples were placed in a crucible, and the crucible containing the samples was placed in a muffle furnace at 1000°C in air Roasting in the atmosphere for 4h, the magnesium aluminum spinel (MgAl 2 o 4 )sample;

[0024] (2), the 71wt.% MgAl prepared above 2 o 4 , 15wt.%K 2 CO 3 , 14wt.% TiO 2 After mixing evenly, add an appropriate amount of distilled water, knead, and extrude at room temperature;

[0025] (3) Place the prepared molded sample in an oven and dry it at 120°C for 2 hours;

[0026] (4) Pour the dried sample into a crucible, put the crucible containing the sample into a muffle furnace, and roast it in an air atmosphere at 600°C for 4 hours to obtain a catalyst sample. The MgAl in the catalyst sample 2 o 4 71wt.%, ...

Embodiment 2

[0029] A kind of preparation method of magnesia-aluminum spinel-based medium-temperature carbonyl sulfide hydrolysis catalyst is as follows:

[0030] (1), 43.07wt.% magnesium carbonate and 56.93wt.% pseudo-boehmite mechanically and uniformly mixed samples were placed in a crucible, and the crucible containing the samples was placed in a muffle furnace at 1000°C in air Roasting in the atmosphere for 4h, the magnesium aluminum spinel (MgAl 2 o 4 )sample;

[0031] (2), the 71wt.% MgAl prepared above 2 o 4 , 14wt.% K 2 CO 3 , 15wt.% TiO 2 After mixing evenly, add an appropriate amount of distilled water, knead, and extrude at room temperature;

[0032] (3) Place the prepared molded sample in an oven and dry it at 120°C for 2 hours;

[0033](4) Pour the dried sample into a crucible, put the crucible containing the sample into a muffle furnace, and roast it in an air atmosphere at 600°C for 4 hours to obtain a catalyst sample. The MgAl in the catalyst sample 2 o 4 71wt.%, ...

Embodiment 3

[0036] A kind of preparation method of magnesia-aluminum spinel-based medium-temperature carbonyl sulfide hydrolysis catalyst is as follows:

[0037] (1), 43.07wt.% magnesium carbonate and 56.93wt.% pseudo-boehmite mechanically and uniformly mixed samples were placed in a crucible, and the crucible containing the samples was placed in a muffle furnace at 1000°C in air Roasting in the atmosphere for 4h, the magnesium aluminum spinel (MgAl 2 o 4 )sample;

[0038] (2), the 85wt.% MgAl prepared above 2 o 4 , 10wt.% K 2 CO 3 , 5wt.% TiO 2 After mixing evenly, add an appropriate amount of distilled water, knead, and extrude at room temperature;

[0039] (3) Place the prepared molded sample in an oven and dry it at 120°C for 2 hours;

[0040] (4) Pour the dried sample into a crucible, put the crucible containing the sample into a muffle furnace, and roast it in an air atmosphere at 600°C for 4 hours to obtain a catalyst sample. The MgAl in the catalyst sample 2 o 4 85wt.%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com