Bifunctional coupling catalyst realizing medium-temperature hydrolysis conversion of carbonyl sulfide and deoxygenation and preparation method

A catalyst and carbonyl sulfide technology, which is applied in the field of medium temperature gas purification and catalyst preparation, can solve the problems of overall performance decline, poisoning, expensive price of precious metal catalysts, etc., and achieve the effect of improving the anti-oxygen and sulfur poisoning performance and stabilizing the medium temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

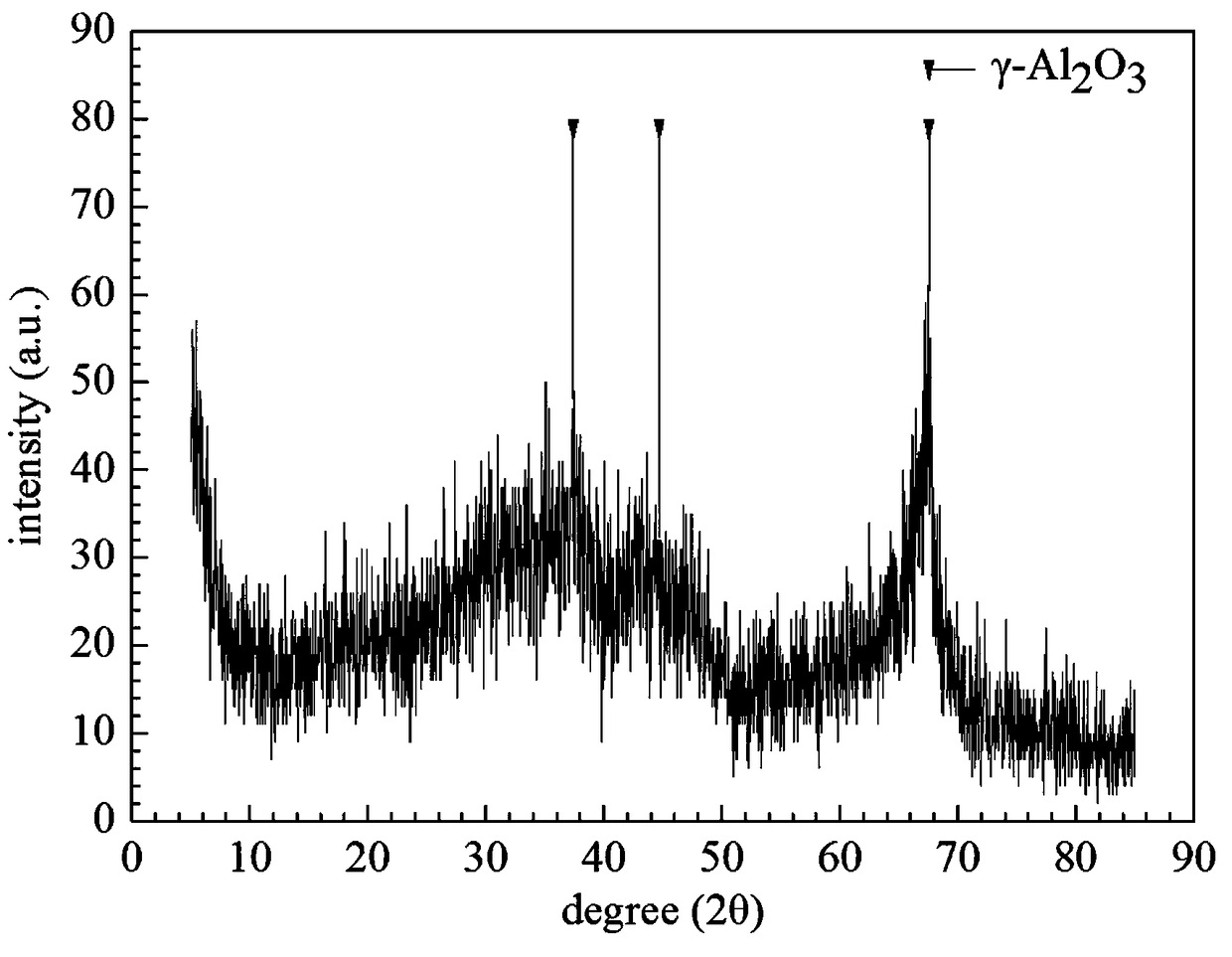

Image

Examples

Embodiment 1

[0020] A method for preparing a catalyst capable of simultaneously removing oxygen and hydrolyzing and converting carbonyl sulfide under moderate temperature conditions is as follows:

[0021] (1), Weigh 15g potassium carbonate and 12.24g ammonium molybdate in distilled water to fully dissolve it to make a mixed solution, put the made mixed solution in a magnetic stirrer and stir continuously at high speed, so that the ions in the solution are evenly mixed;

[0022] (2) Dip the mixed solution into 75g of a spherical alumina carrier with a particle size of φ3~5mm with a water absorption rate of 55%, and seal the container containing the alumina carrier and let it stand for 12h;

[0023] (3) Open and seal the container after standing for 12 hours, place it in an oven, and dry it at 120°C for 4 hours;

[0024] (4) Pour the dried sample into the crucible, put the crucible with the sample into the muffle furnace, and roast it in the air atmosphere at 550°C for 5 hours to obtain the roasted ...

Embodiment 2

[0028] A method for preparing a catalyst capable of simultaneously removing oxygen and hydrolyzing and converting carbonyl sulfide under moderate temperature conditions is as follows:

[0029] (1) Weigh 10g potassium carbonate and 6.12g ammonium molybdate and dissolve them in distilled water to make a mixed solution. Place the mixed solution in a magnetic stirrer and stir continuously at high speed, so that the ions in the solution are evenly mixed. ;

[0030] (2) Dip the mixed solution into 85g of a spherical alumina carrier with a particle size of φ3~5mm with a water absorption rate of 55%, and seal the container containing the alumina carrier and let it stand for 12h;

[0031] (3) Open and seal the container after standing for 12 hours, place it in an oven, and dry it at 120°C for 4 hours;

[0032] (4) Pour the dried sample into the crucible, put the crucible with the sample into the muffle furnace, and roast it in the air atmosphere at 550°C for 5 hours to obtain the roasted sampl...

Embodiment 3

[0036] A method for preparing a catalyst capable of simultaneously removing oxygen and hydrolyzing and converting carbonyl sulfide under moderate temperature conditions is as follows:

[0037] (1) Weigh 15g potassium carbonate and 12.24g ammonium molybdate and dissolve them fully in distilled water to make a mixed solution. Place the mixed solution in a magnetic stirrer and stir continuously at high speed, so that the ions in the solution are evenly mixed. ;

[0038] (2) Dip the mixed solution into 75g of a spherical alumina carrier with a particle size of φ3~5mm with a water absorption rate of 55%, and seal the container containing the alumina carrier and let it stand for 12h;

[0039] (3) Open and seal the container after standing for 12 hours, place it in an oven, and dry it at 120°C for 4 hours;

[0040] (4) Pour the dried sample into the crucible, put the crucible with the sample into the muffle furnace, and roast it in the air atmosphere at 550°C for 5 hours to obtain the roaste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com