Chemical equipment cleaning device

A technology for cleaning devices and chemical equipment, applied to cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as inability to do all-round cleaning, complicated operation, and waste of electric energy, so as to avoid waste of electric power resources , saving water resources, all-round cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

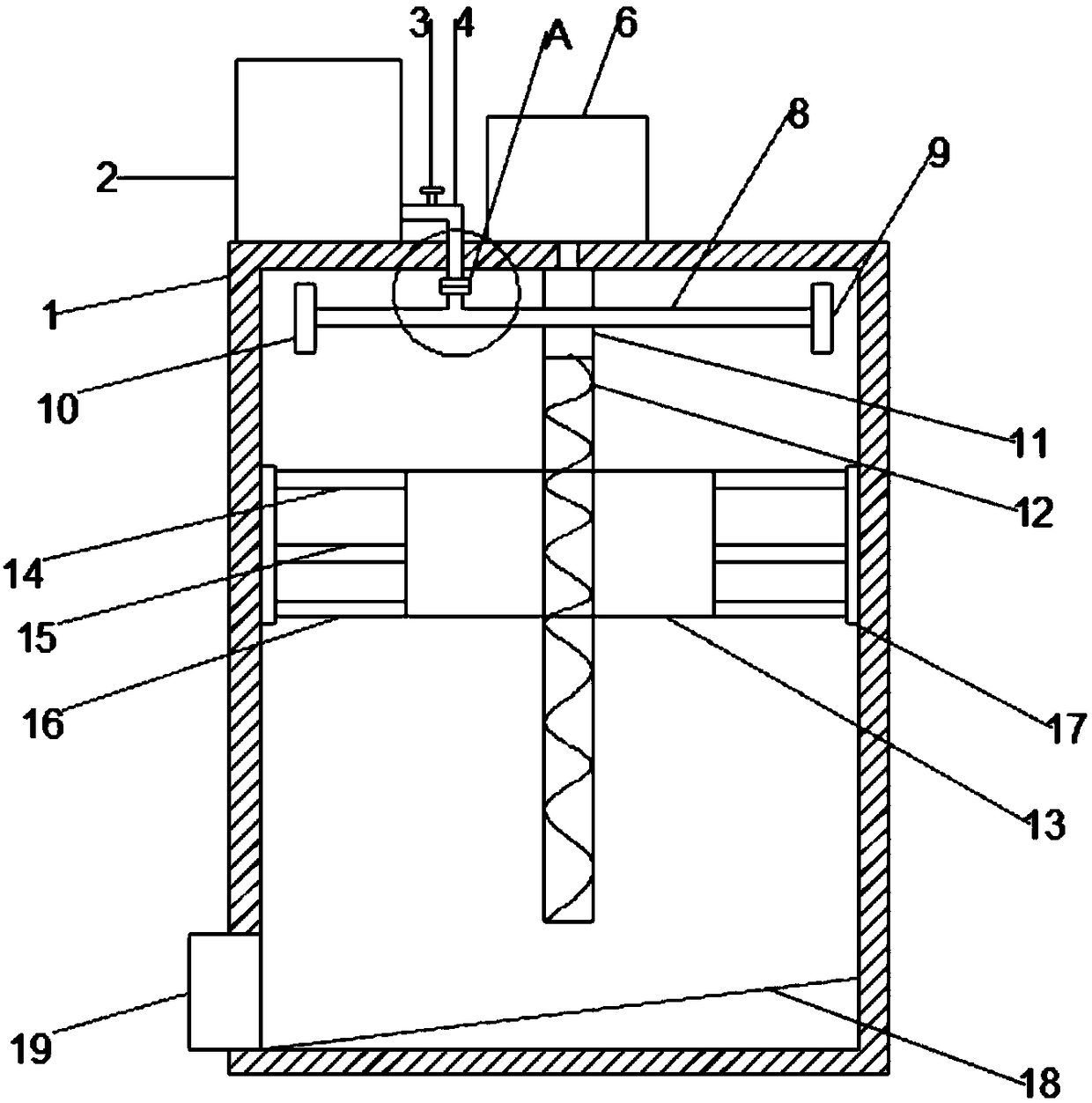

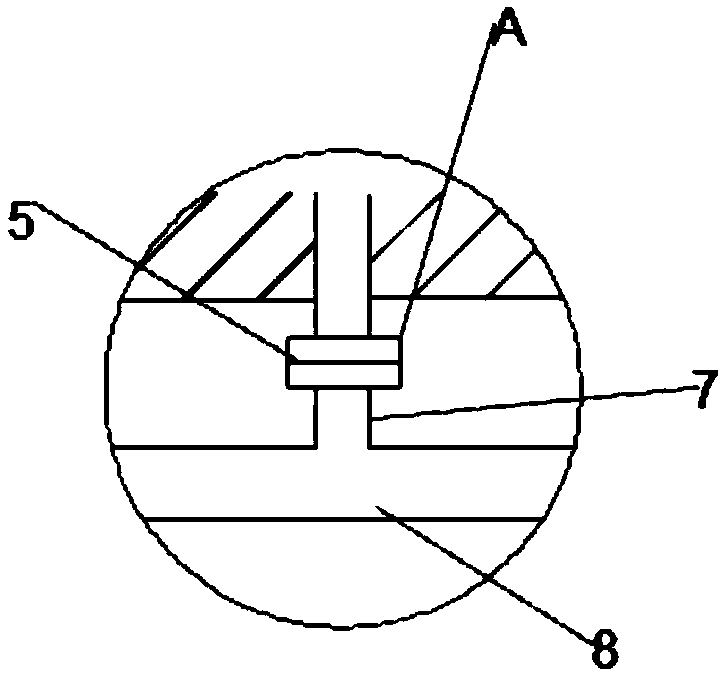

[0023] see Figure 1~2 , in an embodiment of the present invention, a chemical equipment cleaning device includes a main body 1, a water tank 2 is provided on the left side of the top outer surface of the main body 1, the water tank 2 is used to store water, and the bottom of the right wall of the water tank 2 It communicates with the left end of the first water pipe 4, the first water pipe 4 is "L" shaped, the right end of the transverse part of the first water pipe 4 is provided with a valve 3 on the outside of the water tank 2, the longitudinal direction of the first water pipe 4 The top part of the main body 1 is connected to the rotary connector 5, and the bottom of the rotary connector 5 is connected to the upper end of the second water pipe 7. The second water pipe 7 is arranged on the horizontal water pipe 8 and connected to the horizontal water pipe 8. Through, the middle outer surface of the horizontal water pipe 8 is fixedly connected with the middle outer surface o...

Embodiment 2

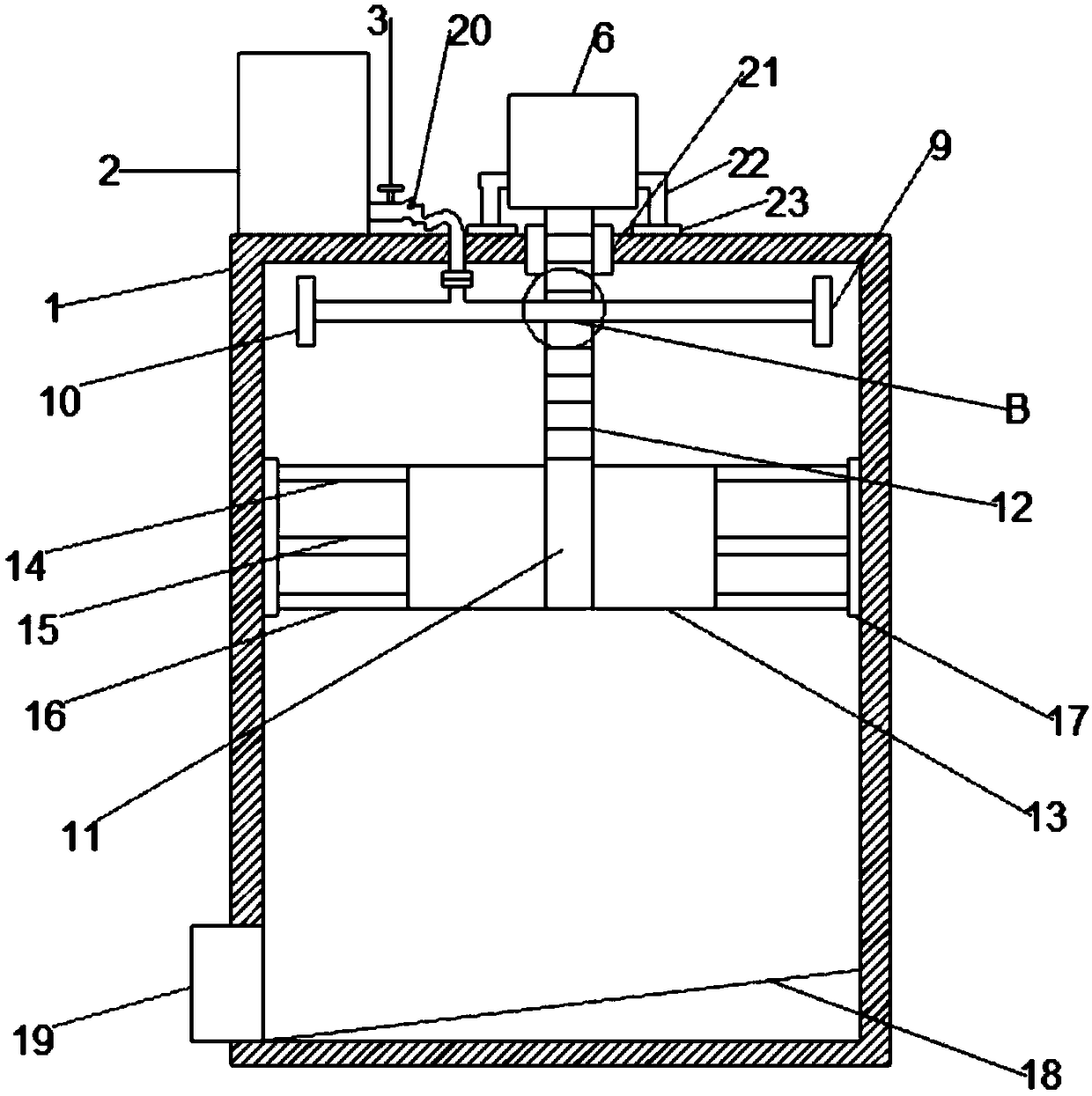

[0025] see Figure 3-4 The difference between embodiment 2 and embodiment 1 is that the first water pipe 4 is replaced by a hose 20, the length of the hose 20 can satisfy the motor 6 to move up and down, and the lower ends of the left and right sides of the motor 6 are symmetrically provided with L Rod 22, the lower end of the L rod 22 is fixedly connected with a limit block 23, and the limit block 23 is made of elastic material, which plays the role of buffering and protecting the motor 6, and the output shaft of the motor 6 is fixedly connected with a threaded rod 12. The threaded rod 12 is provided with a threaded connecting threaded plate 24, the connecting threaded plate 24 is provided with a through hole 25 penetrating with the matching threaded rod 12, the front side of the connecting threaded plate 24 is connected to the horizontal water pipe 8 The outer surface of the threaded rod 12 is fixedly connected, the threaded rod 12 runs through the top of the main body 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com