Coil stripping method for steel coil trolley

A steel coil trolley and trolley technology, which is applied in the field of unloading steel coil trolleys, can solve the problems that the steel coil cannot be removed from the coiling mandrel, easily deformed, and the trolley lateral movement is blocked, etc., so as to improve the success rate and stability. , Improve productivity and ensure stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

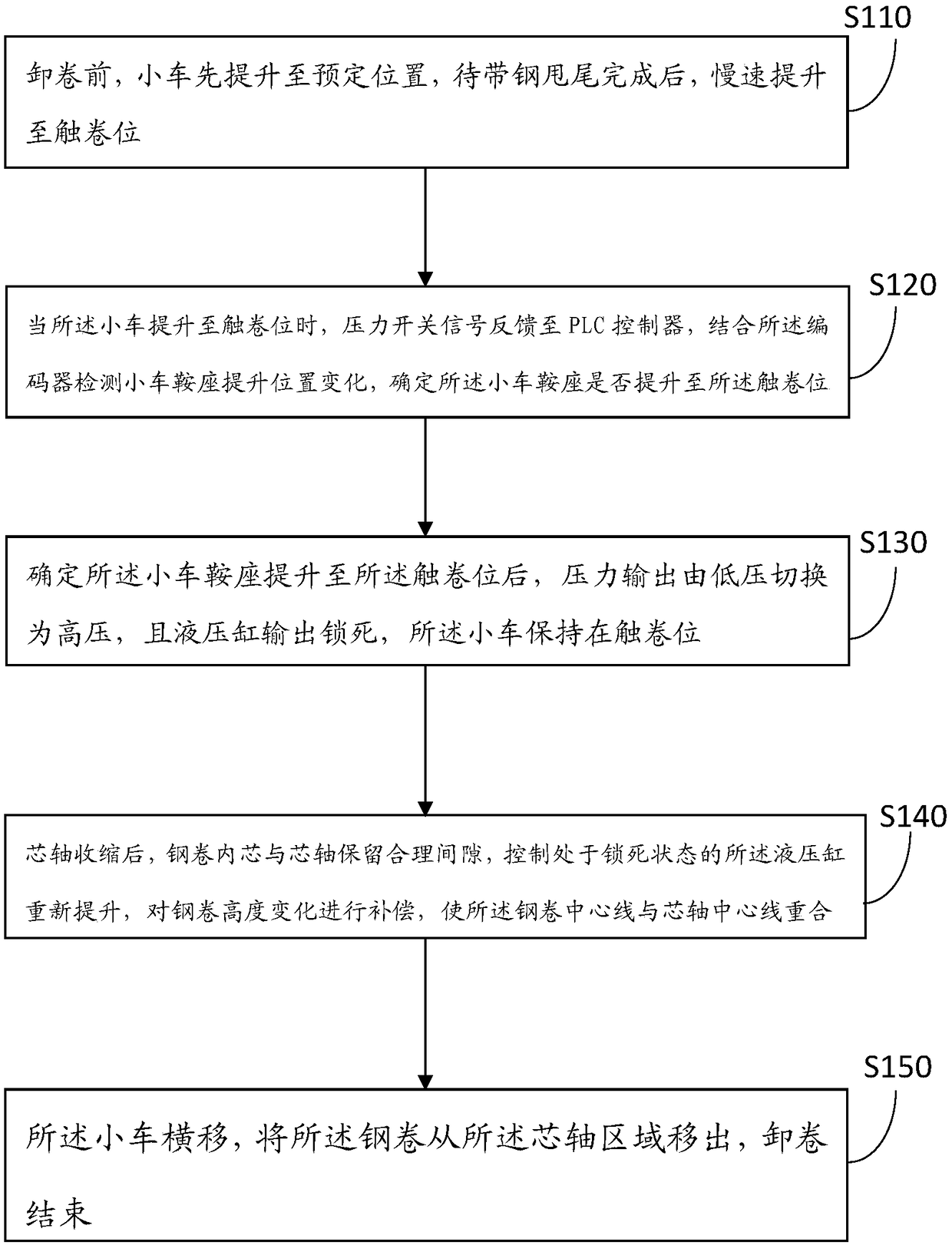

[0023] Such as figure 1 As shown, the embodiment of the present invention provides a method for unloading a steel coil trolley, the method comprising:

[0024] Step 110: Before unloading the coil, the trolley is first lifted to the predetermined position, and after the strip steel flick is completed, it is slowly lifted to the roll touching position;

[0025] Specifically, the saddle of the coil unloading trolley is lowered to a low position and enters under the coiler. After the tailing of the strip steel is completed, the trolley starts to lift slowly. Location. The traversing action is driven by a variable frequency motor, and the traversing position measuring device is a laser range finder, which measures the displacement of the trolley in real time. The hoisting position of the trolley is calculated by the encoder, and the judgment of the rolling position of the saddle of the trolley is realized by simultaneous detection of the encoder and the hydraulic pressure switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com