Sand core removing system with aluminum casting water

A sand core and sand remover technology, applied in the field of foundry equipment, can solve the problems of high physical strength of operators, harsh operating environment, and long waiting time, and achieve the effects of reducing labor intensity, convenient and efficient operation, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

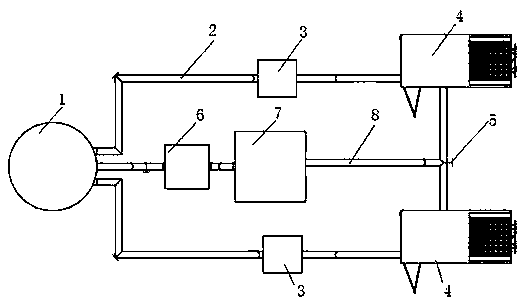

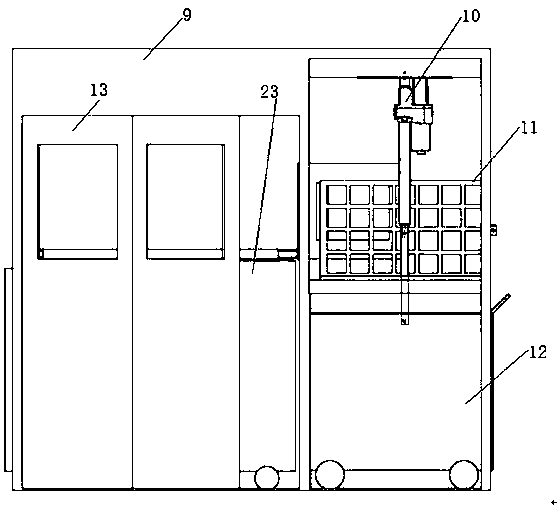

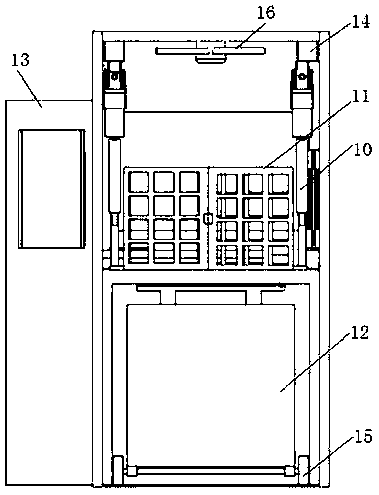

[0021] Specific embodiments: the present invention provides an aluminum casting water desander core system, including a water desander 4, a filter 7, a high temperature slurry pump 6, a water tank 1 and a water pump 3, the water desander 4 The water outlet is connected to the filter 7 and the high-temperature slurry pump 6 sequentially through the water outlet pipeline 8, the inlet of the water tank 1 is connected to the outlet of the high-temperature slurry pump 6, and the outlet 19 of the water tank 1 passes through the water inlet pipe The road 2 communicates with the water inlet of the water desander 4 , and the water pump 3 is arranged on the water inlet pipe 2 . The water desander 4 can be provided with one or more groups. Through this design, the present invention can control the water temperature in the water desander to ensure that the parts will not explode in the water to effectively remove the sand cores in the parts, and can realize self-cleaning and recycling of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap