A Method for Predicting Chatter in NC Milling of Mold Cavities

A CNC milling and cavity technology, applied in milling machine equipment, manufacturing tools, milling machine equipment details, etc., can solve the problems of low accuracy of milling chatter prediction, affect the quality of mold cavity processing, and speed up tool failure, etc., to achieve the prediction process Convenience and quickness, accurate chatter prediction, and guaranteed processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific implementation manner 1: The specific process of a method for predicting chatter vibration in CNC milling of a mold cavity in this implementation manner is as follows:

[0032] Step 1. Establish the relative transfer function of the tool-workpiece system;

[0033] Obtaining the dynamic characteristics of the tool-workpiece system, that is, the transfer function matrix, is an important prerequisite for the stability prediction of the milling process. Most of the previous studies only considered the dynamic characteristics of the tool system, and ignored the influence of the workpiece system on the dynamic characteristics of the overall machining system. The present invention comprehensively considers the dynamic characteristics of the tool subsystem and the workpiece subsystem, based on the relative transfer function. The overall dynamic model of the tool-workpiece system.

[0034] Obtain the transfer function of the tool subsystem and the workpiece subsystem respecti...

specific Embodiment approach 2

[0042] Second embodiment: This embodiment is different from the first embodiment in that in the second step, the relative transfer function of the tool-workpiece system obtained in step one is introduced into the three-dimensional milling stability model to obtain the milling chatter frequency of the milling cutter The critical axial cutting depth at, the specific process is:

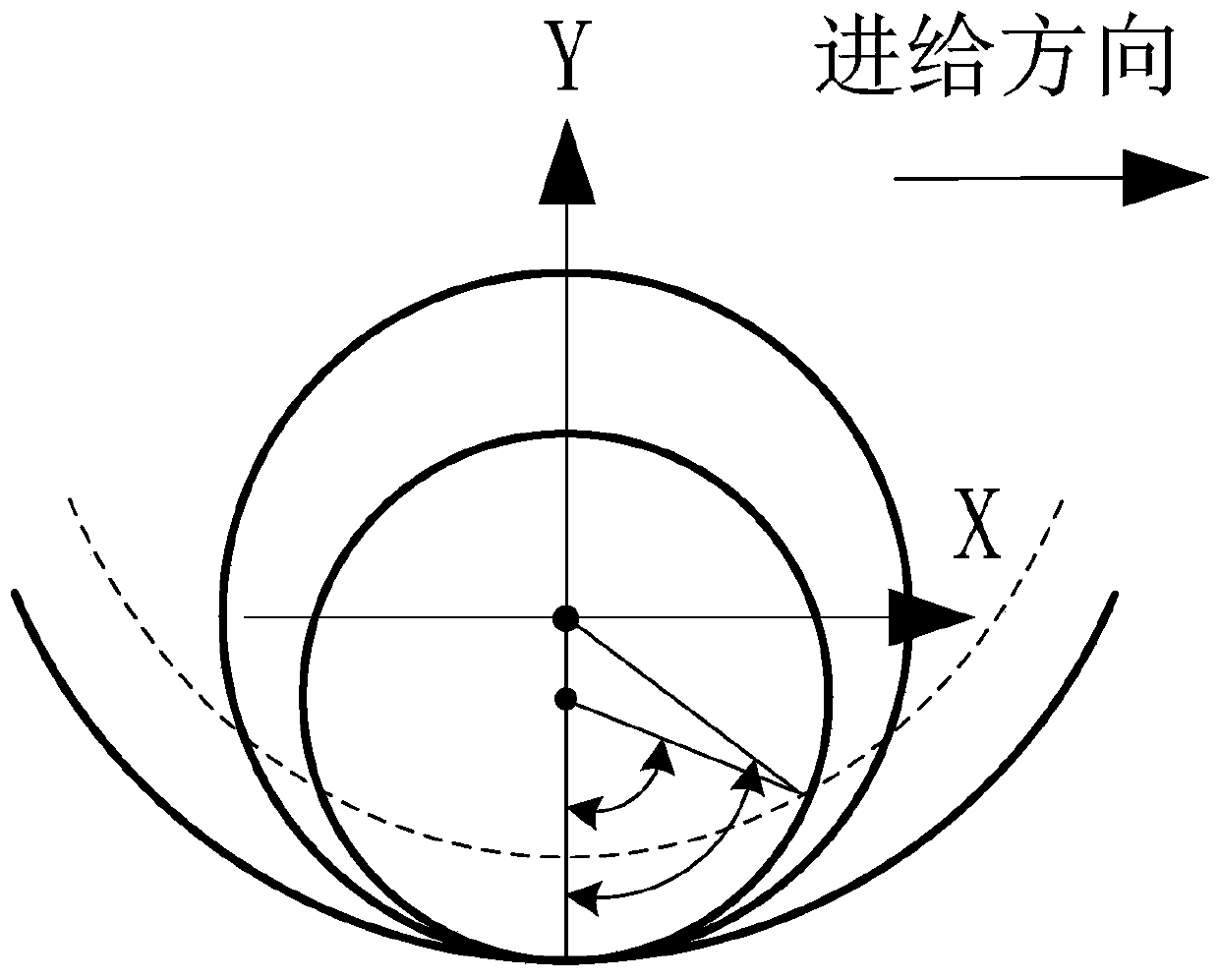

[0043] The three-dimensional milling stability model based on the frequency domain method. When the milling cutter mills the side surface of the mold groove, the tangential force F t Distributed along the milling speed direction of the milling edge of the milling cutter, radial force F r Is the radial direction of milling cutter feed, axial force F a Acts in the axial direction of the milling cutter; in order to consider the general situation, in the milling edge line, the milling edge is divided into a limited number of small differential units. The chip loads and the corresponding differential loads in th...

specific Embodiment approach 3

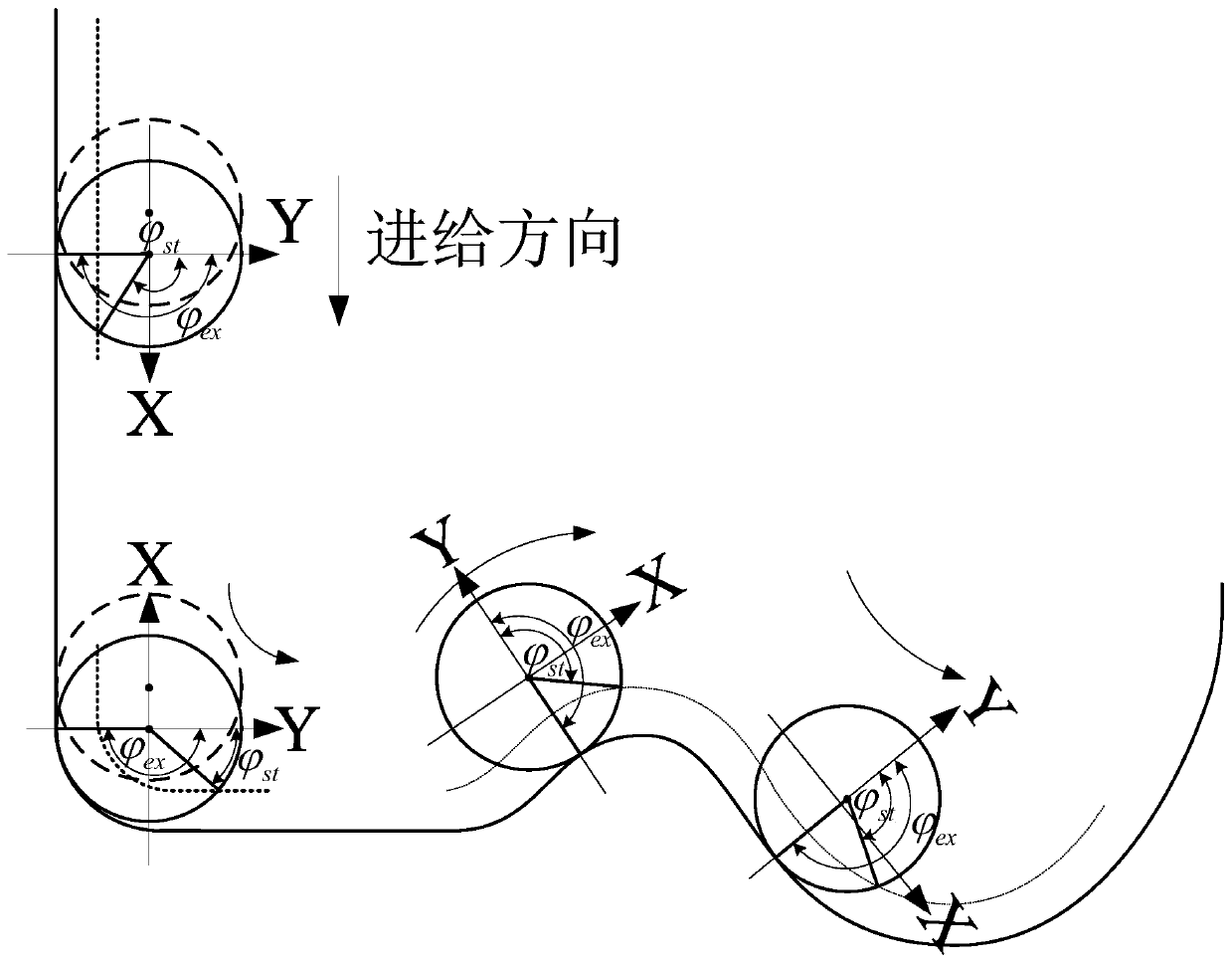

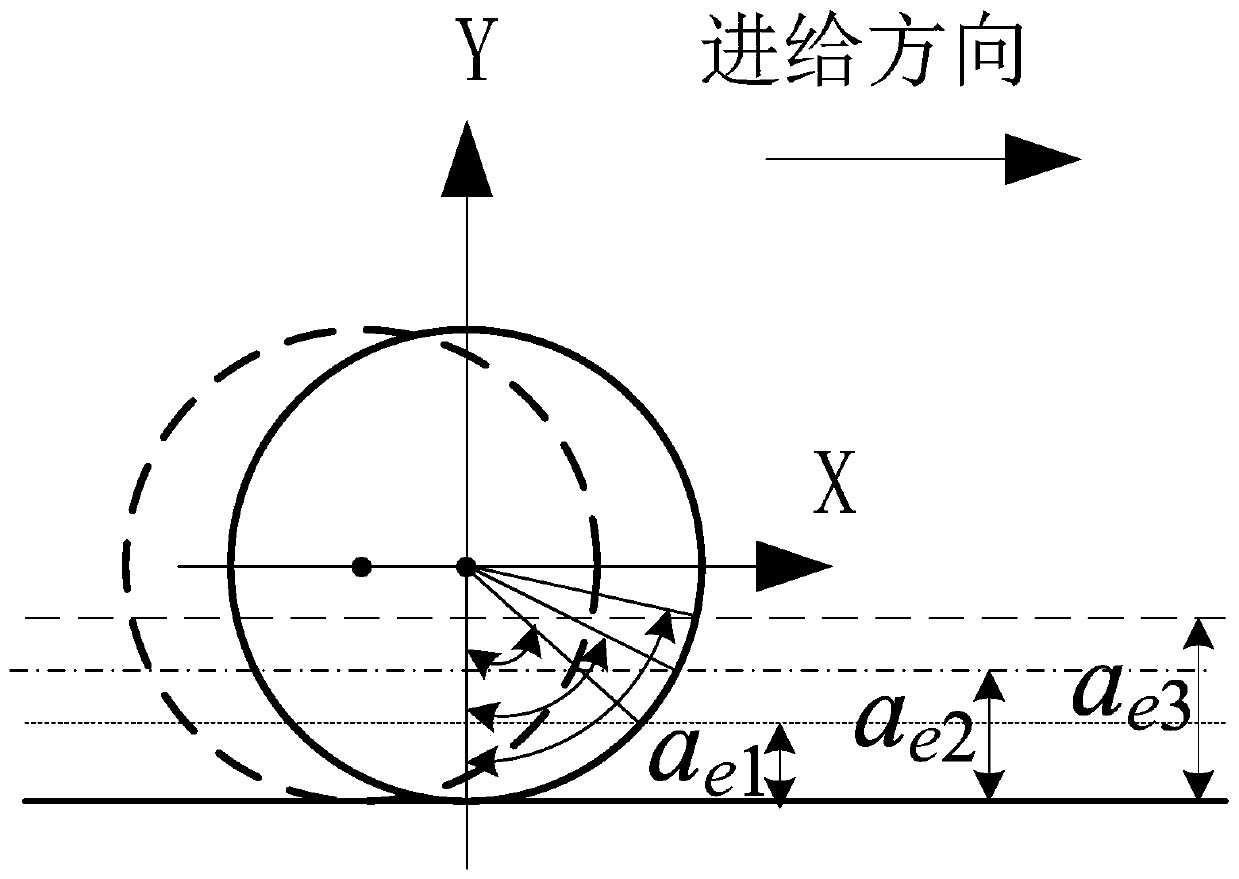

[0100] Specific embodiment three: This embodiment is different from specific embodiment one or two in that when the tool is down milling, the horizontal cut-in angle and cut-out angle of the cutter tooth are respectively with The formula is:

[0101]

[0102] Where R c Is the tool radius, a e Is the radial depth of cut;

[0103] When the tool is up-milling, the horizontal cut-in angle and cut-out angle of the tooth are respectively with The formula is:

[0104]

[0105] Other steps and parameters are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com