Rubber supply device for low-pressure injection molding equipment

A technology of forming equipment and glue supply device, applied in the field of wire harness processing, can solve the problems of limited heating area and clogging, and achieve the effect of reducing clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

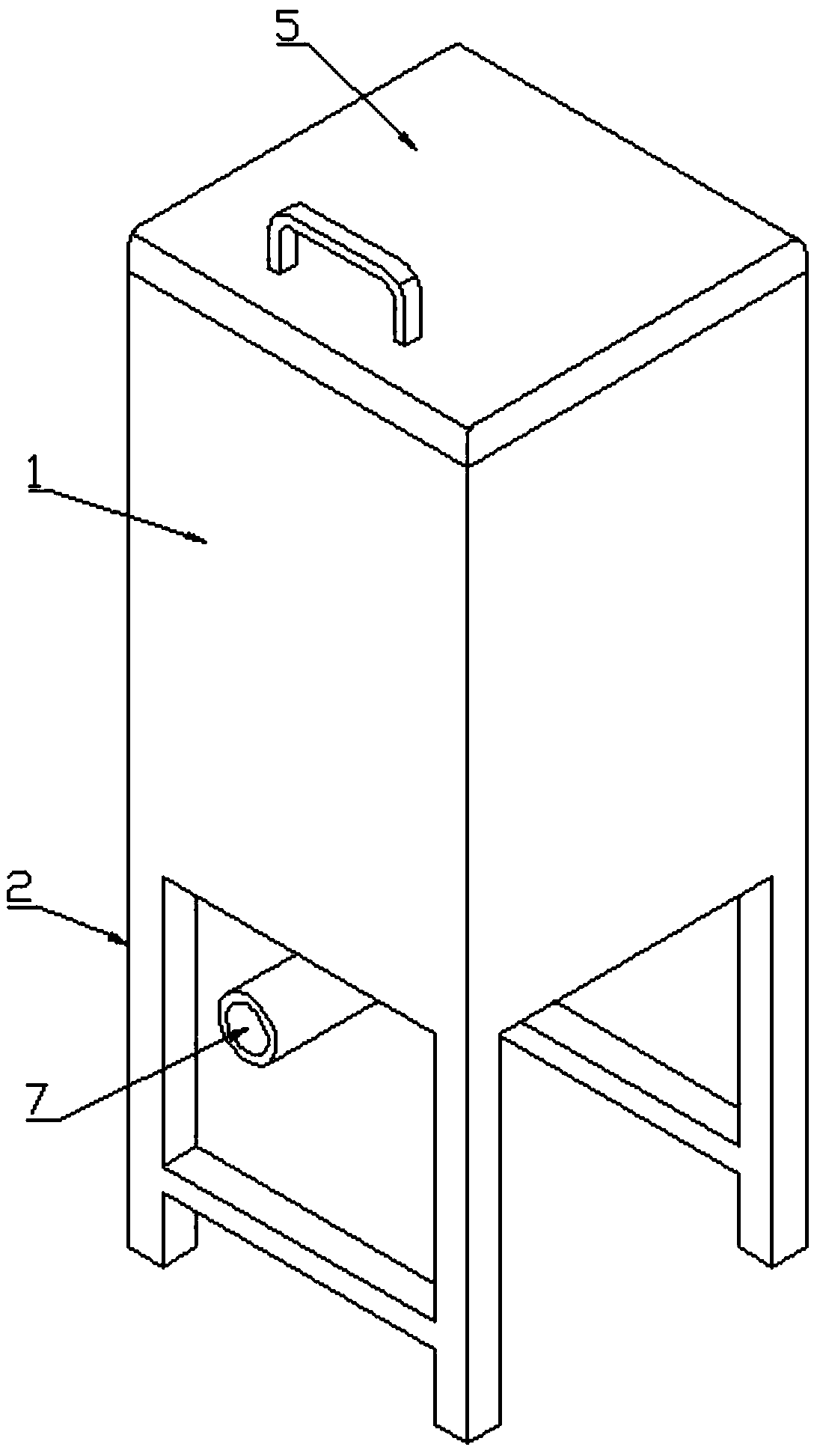

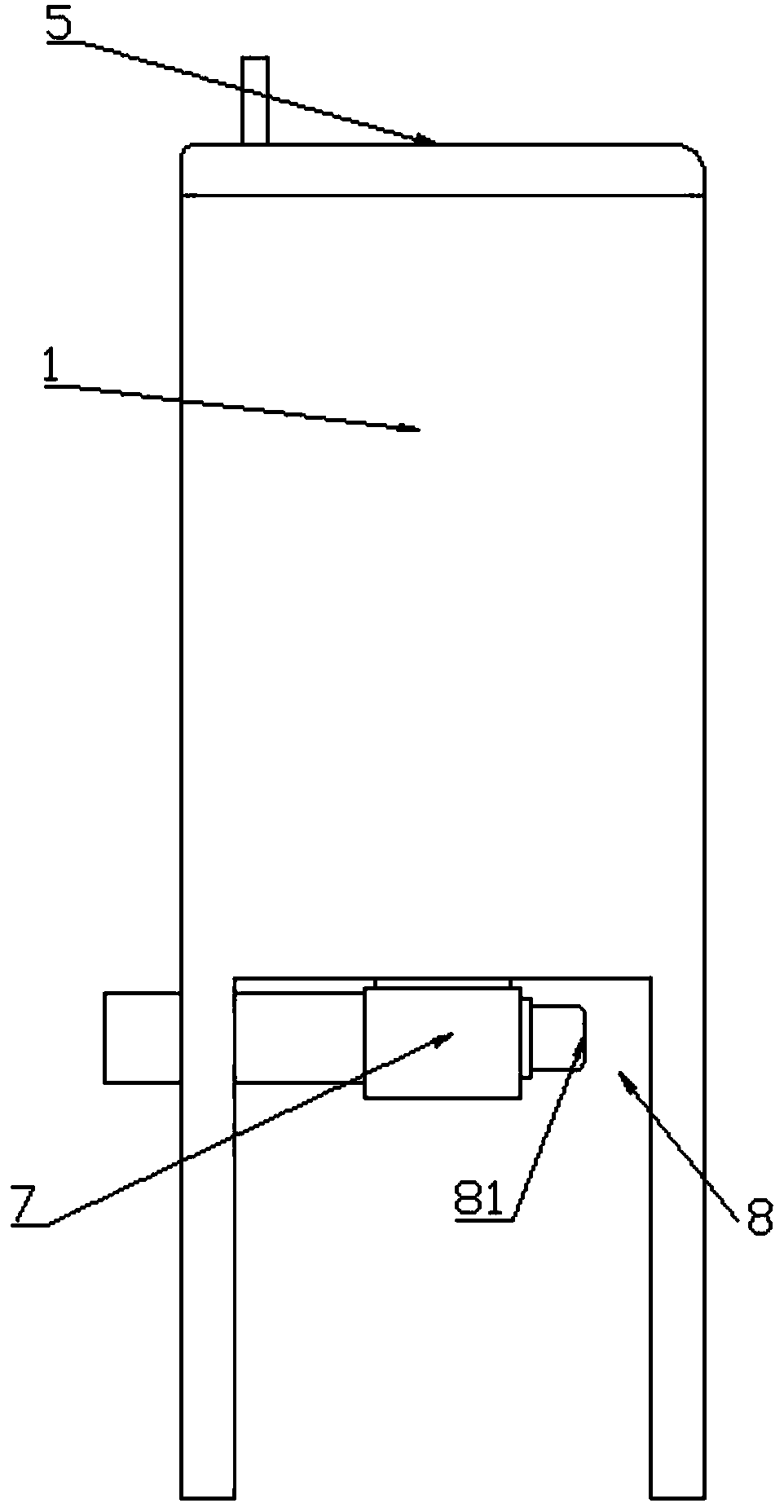

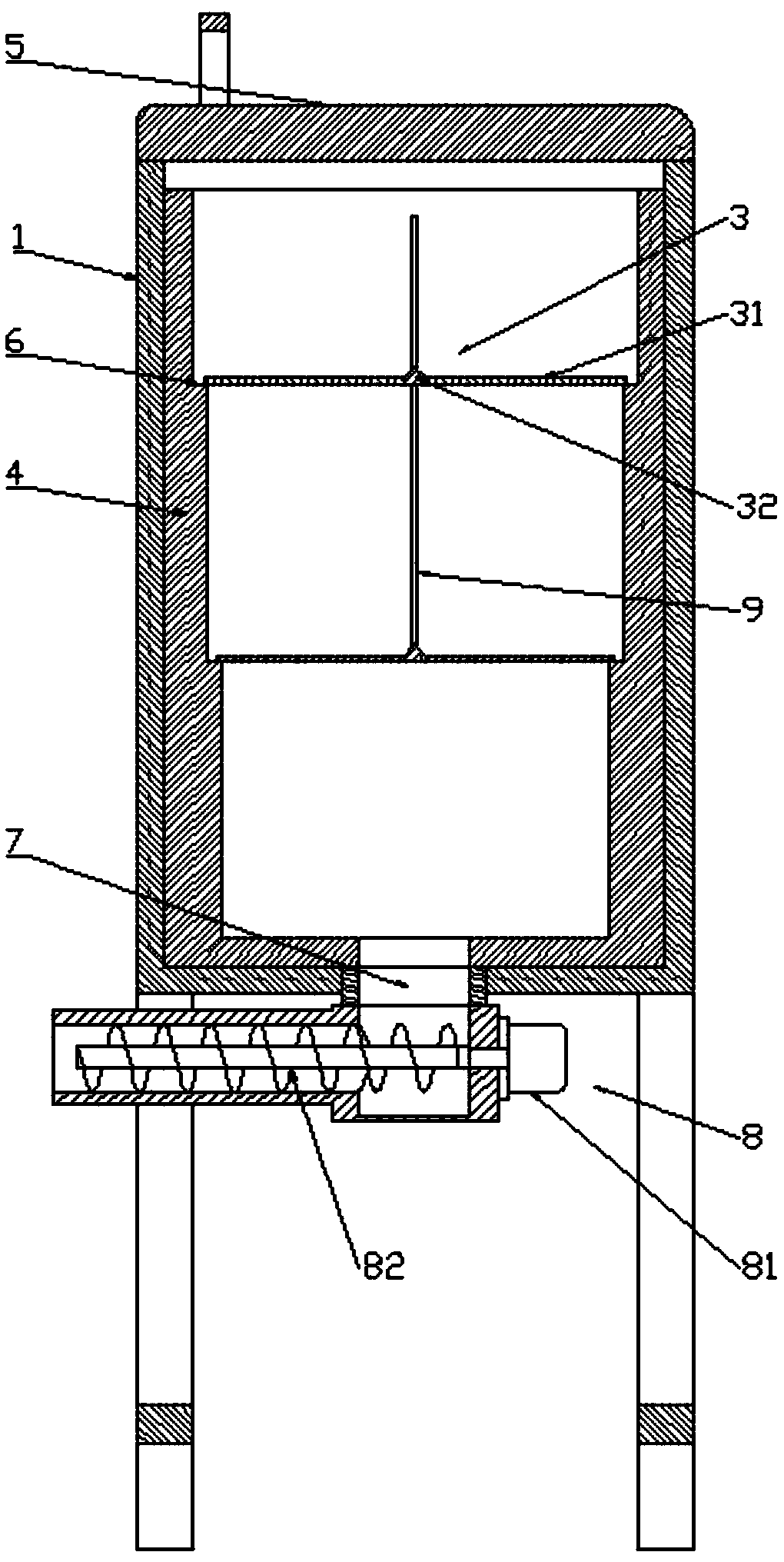

[0025] Such as Figure 1 to Figure 6 As shown, a glue supply device for low-pressure injection molding equipment includes a body 1, a support frame 2, an electric heating grid plate 3 and a heat-insulating liner 32, the support frame 2 is connected to the bottom of the body 1, and the The heat-insulating liner 32 is installed in the body 1. The top of the body 1 is provided with a feed port and hinged with a top cover 5. The heat-insulating liner 32 is cylindrical, and the inner wall of the heat-insulating liner 32 is provided with several steps. surface 6, and from bottom to top, the inner diameter of the step surface 6 increases sequentially, the electric heating grid plate 3 is placed on the step surface 6, and from bottom to top, the aperture of the electric heating grid plate 3 increases successively, the said The bottom of the heat-insulating liner 32 is provided with a glue discharge port 7, and a spiral discharge mechanism 8 is installed at the glue discharge port 7; ...

Embodiment 2

[0031] Such as Figure 7 As shown, a glue supply device for low-pressure injection molding equipment includes a body 1, a support frame 2, an electric heating grid plate 3 and a heat-insulating liner 32, the support frame 2 is connected to the bottom of the body 1, and the The heat-insulating liner 32 is installed in the body 1. The top of the body 1 is provided with a feed port and hinged with a top cover 5. The heat-insulating liner 32 is cylindrical, and the inner wall of the heat-insulating liner 32 is provided with several steps. surface 6, and from bottom to top, the inner diameter of the step surface 6 increases sequentially, the electric heating grid plate 3 is placed on the step surface 6, and from bottom to top, the aperture of the electric heating grid plate 3 increases successively, the said The bottom of the heat-insulating liner 32 is provided with a glue discharge port 7, and a spiral discharge mechanism 8 is installed at the glue discharge port 7;

[0032] Des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com