Novel sheet processing method

A processing method and a new type of plate technology, applied in metal processing, other household appliances, flat products, etc., can solve the problems of insufficient environmental protection, many processes, and high ink costs, and achieve the effect of fewer processes, improved production efficiency, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of processing method of novel plate is characterized in that, comprises the following steps:

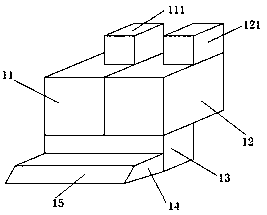

[0032] S1. Add two different raw materials into the mixing mechanism 1, and obtain the composite plate structure 7 through the forming mechanism;

[0033] S2. Sending the composite sheet into the punching device to form a through hole on one side of the composite sheet;

[0034] S3. The composite sheet is further pressed into shape by a pressing mechanism.

[0035] Further, the composite board includes a diffusion layer 71 and a transparent layer 72, and the transparent layer is located in the middle area of the diffusion layer.

[0036] Further, the diffusion layer is an opaque diffusion layer.

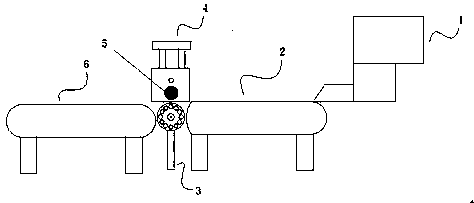

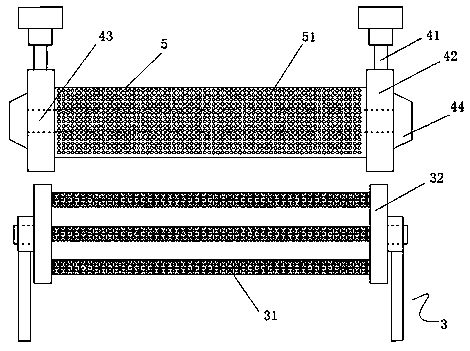

[0037] Further, the punching device includes a first transmission mechanism 2, a roller mechanism 3, and a lifting mechanism 4, and it is characterized in that the lifting mechanism is connected with a pressure roller 5, and the surface of the pressure roller is symmetrica...

Embodiment 2

[0049] A kind of processing method of novel plate is characterized in that, comprises the following steps:

[0050] S1. Add two different raw materials into the mixing mechanism 1, and obtain the composite plate structure 7 through the forming mechanism;

[0051] S2. Sending the composite sheet into the punching device to form a through hole on one side of the composite sheet;

[0052] S3. The composite sheet is further pressed into shape by a pressing mechanism.

[0053] Further, the composite board includes a diffusion layer 71 and a transparent layer 72, and the transparent layer is located in the middle area of the diffusion layer.

[0054] Further, the diffusion layer is an opaque diffusion layer.

[0055] Further, the punching device includes a first transmission mechanism 2, a roller mechanism 3, and a lifting mechanism 4, and it is characterized in that the lifting mechanism is connected with a pressure roller 5, and the surface of the pressure roller is symmetrica...

Embodiment 3

[0065] A kind of processing method of novel plate is characterized in that, comprises the following steps:

[0066] S1. Add two different raw materials into the mixing mechanism 1, and obtain the composite plate structure 7 through the forming mechanism;

[0067] S2. Sending the composite sheet into the punching device to form a through hole on one side of the composite sheet;

[0068] S3. The composite sheet is further pressed into shape by a pressing mechanism.

[0069] Further, the composite board includes a diffusion layer 71 and a transparent layer 72, and the transparent layer is located in the middle area of the diffusion layer.

[0070] Further, the diffusion layer is an opaque diffusion layer.

[0071] Further, the punching device includes a first transmission mechanism 2, a roller mechanism 3, and a lifting mechanism 4, and it is characterized in that the lifting mechanism is connected with a pressure roller 5, and the surface of the pressure roller is symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com